USB (universal serial bus) connector capable of being positively and negatively plugged and manufacturing method for USB connector

A connector, positive and negative insertion technology, applied in the direction of connection, connecting device parts, connecting parts protective grounding/shielding device, etc. Overcome the inability to release the mold and ensure the effect of electrical contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

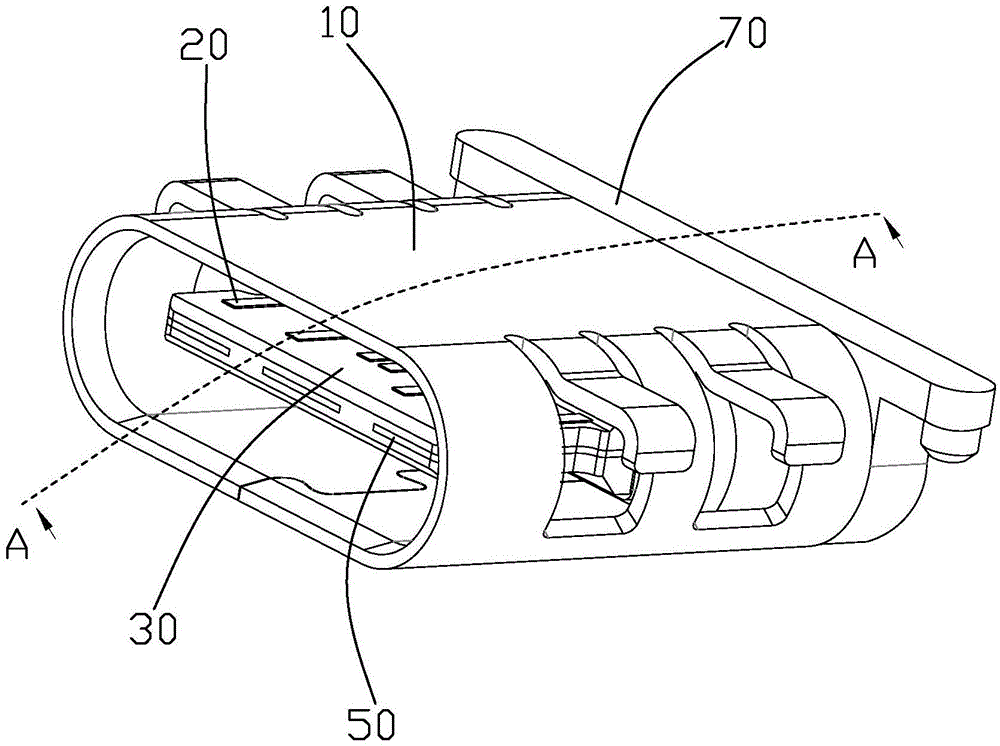

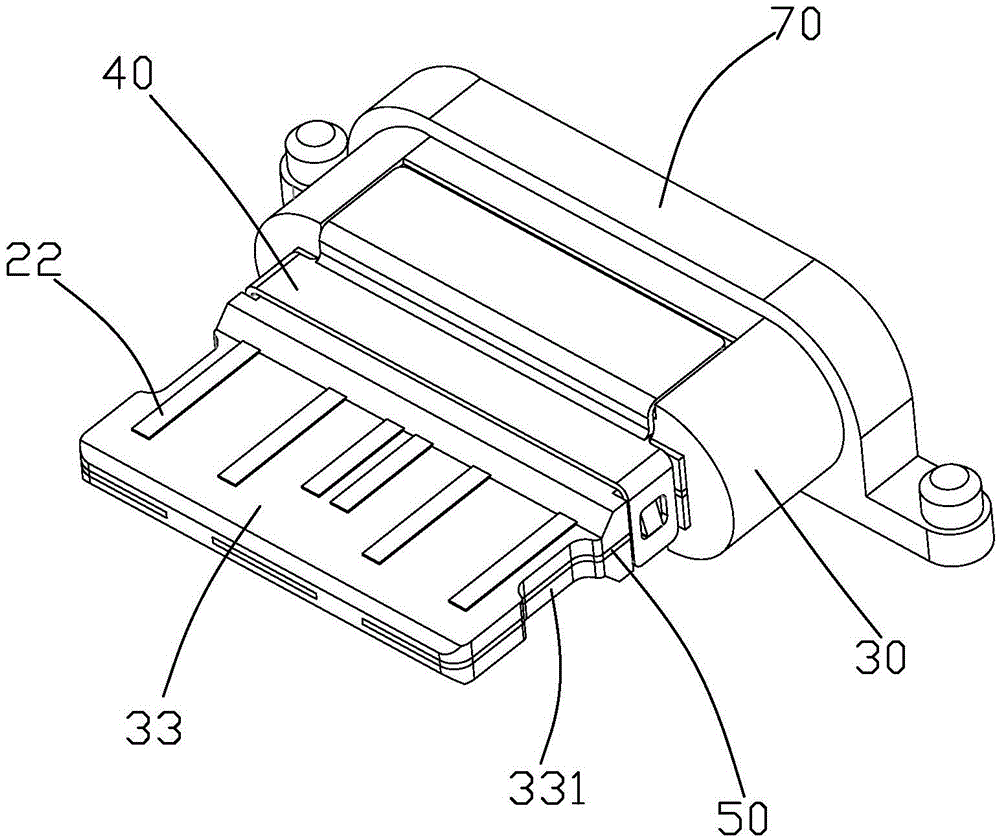

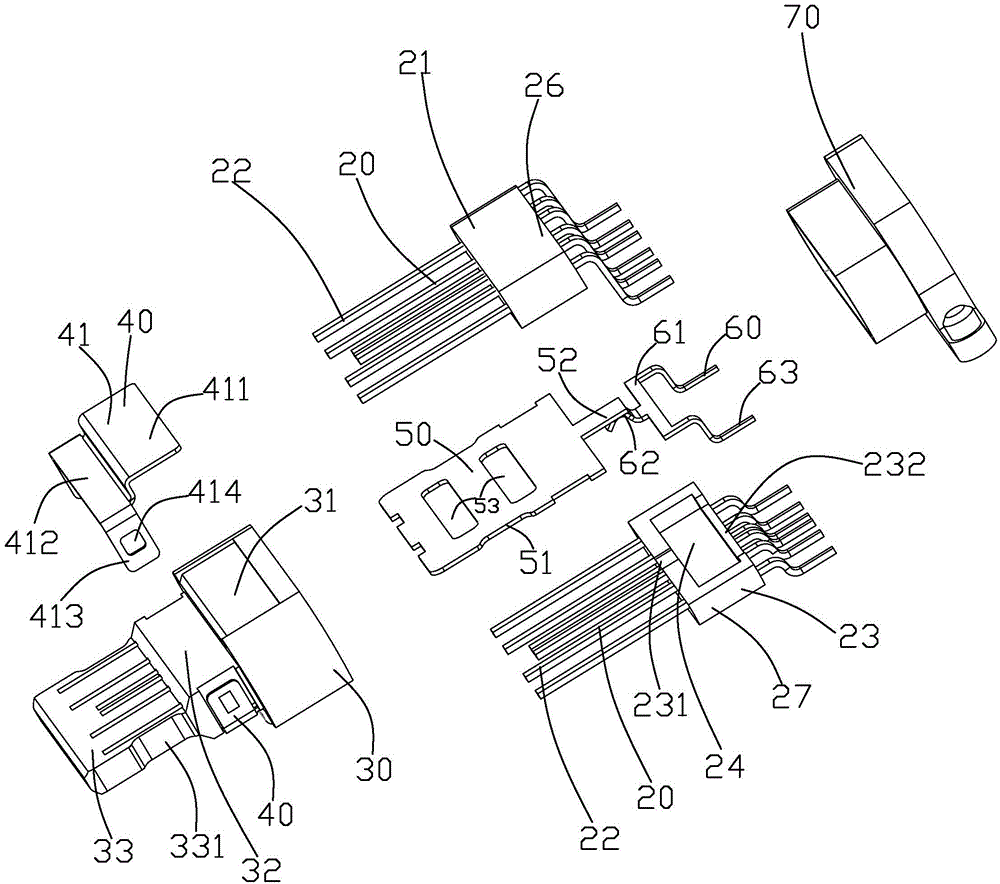

[0026] see Figure 1 to Figure 4 As shown, the reversible USB connector of the present invention includes two conductive terminal groups 20 arranged in upper and lower rows, grounding components 50 and 60 clamped between the upper and lower two conductive terminal groups 20, integrally formed on the The front insulator 30 on the periphery of the upper and lower conductive terminal groups 20, the metal clamping sheet 40 covering the periphery of the front insulator 30, the rear insulator 70 integrally formed on the rear ends of the two conductive terminal groups 20, and the surrounding set The metal casing 10 on the periphery of the front insulator 30 .

[0027] The two conductive terminal groups 20 include an upper terminal group 26 and a lower terminal group 27 . The upper terminal group 26 includes an upper insulating base 21 and a plurality of conductive terminals 22 integrally formed and held on the upper insulating base 21 . The lower terminal group 27 includes a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com