Direct-current high-voltage direct-driven LED circuit based on high-power passive harmonic filter

A technology of LED circuits and passive harmonics, applied in the field of electronics, can solve problems such as unusability, and achieve the effects of high reliability, small harmonic distortion and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

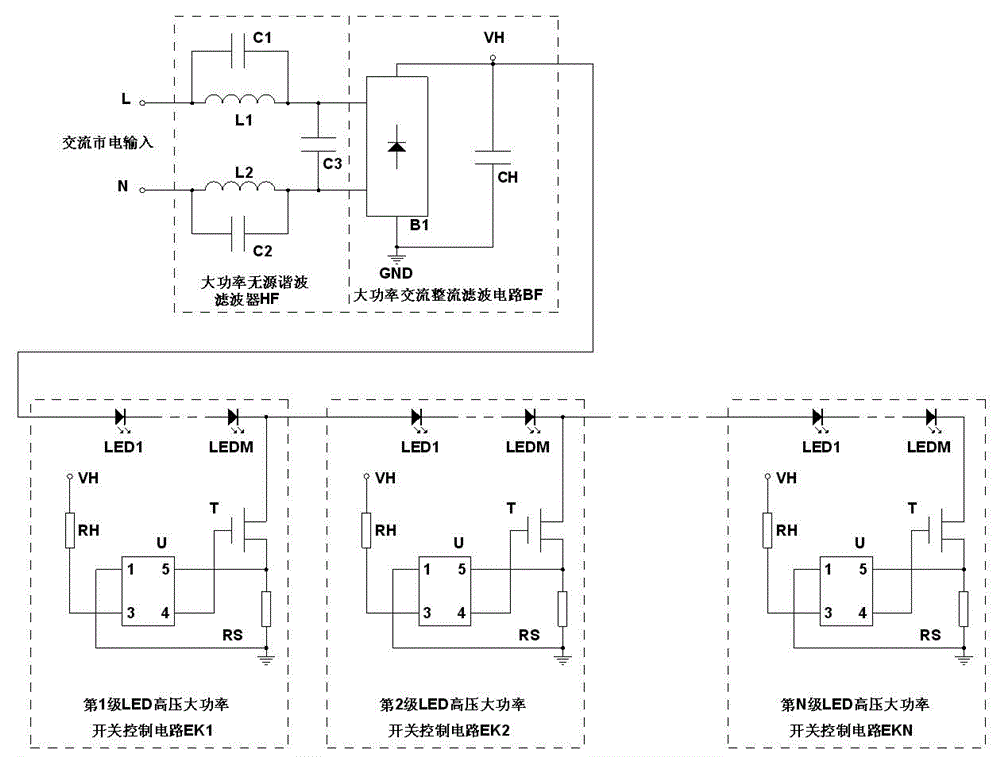

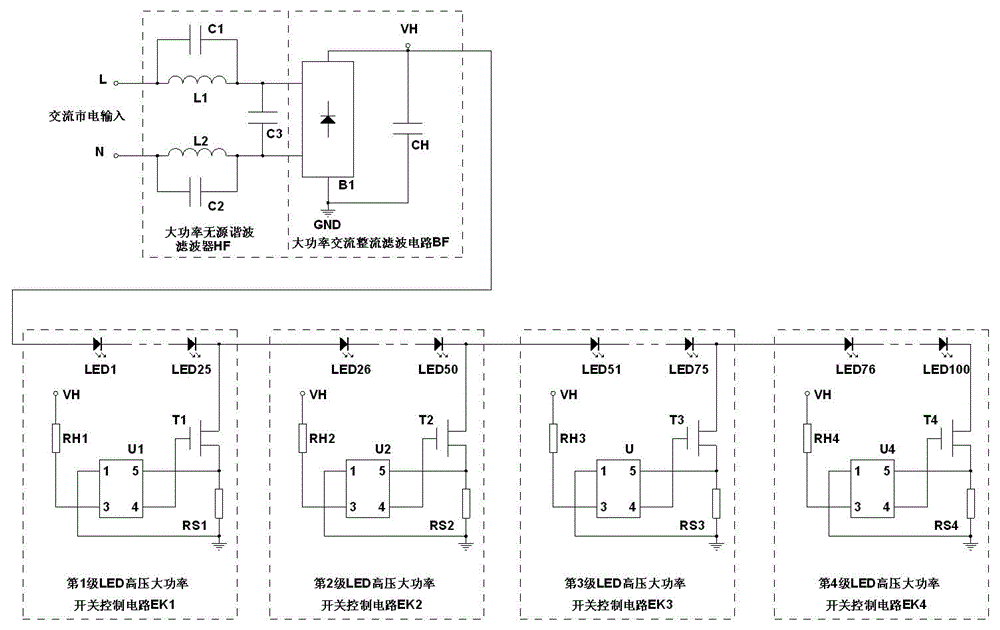

[0033] see figure 2 , figure 2 It is a schematic diagram of a circuit with a power of 500W for the present invention. It consists of high-power passive harmonic filter HF, high-power AC rectification filter circuit BF and LED high-voltage high-power switch control circuit group connected in series. The LED high-voltage high-power switch control circuit group is composed of 4-stage LED high-voltage high-power switch control circuits EK1 to EK4. Among them, the high-power passive harmonic filter HF is composed of inductors L1, L2 and capacitors C1, C2, and C3. L1 and C1 are connected in parallel, one end of which is connected to the L end of the mains, and the other end is an output end of HF. C2 is connected in parallel, one end of which is connected to the N terminal of the mains, and the other end is another output end of HF. The high-power AC mains rectification filter circuit BF includes the mains high-voltage full-wave rectifier bridge B1 and the high-voltage filter ca...

Embodiment 2

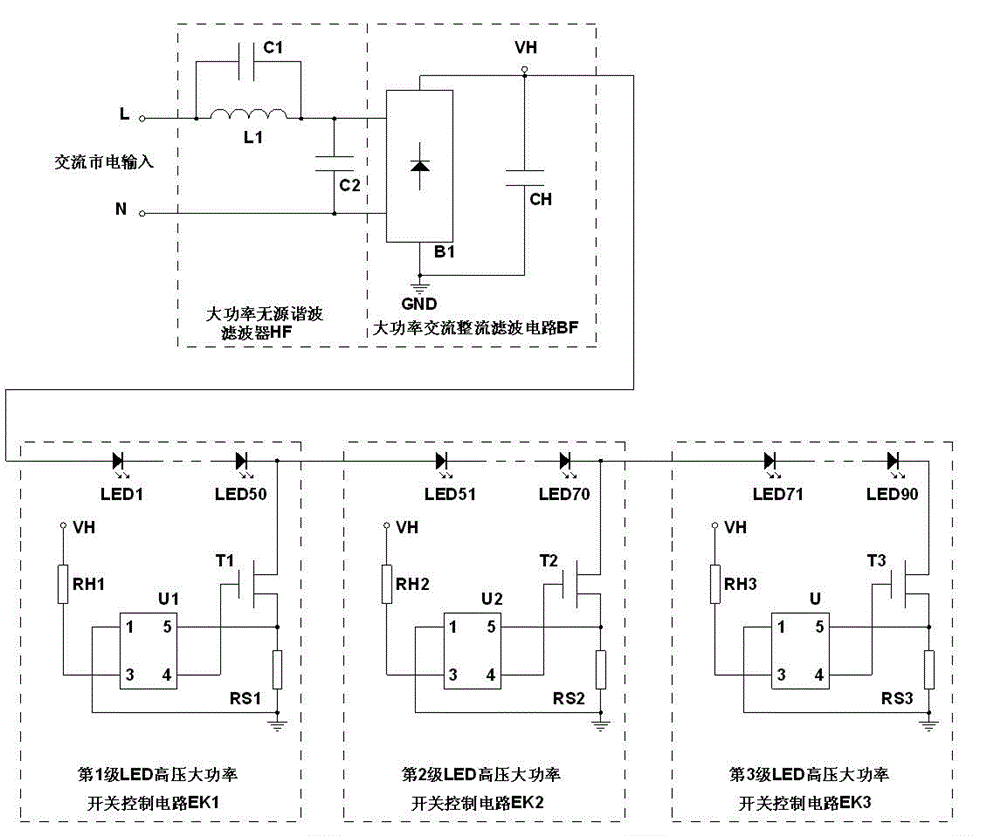

[0041] see image 3 , DC high-voltage direct-drive LED circuit based on high-power passive harmonic filter: It is composed of high-power passive harmonic filter HF, high-power AC rectifier filter circuit BF and LED high-voltage high-power switch control circuit group in series.

[0042] The high-power passive harmonic filter HF is an inductor-capacitor passive harmonic filter. The high-power passive harmonic filter HF is composed of an LC harmonic filter network of more than one level, which is responsible for filtering out the harmonics generated by the high-power AC rectification filter circuit BF, ensuring that the DC high-voltage direct-drive LED circuit provided by the present invention has High power factor of 0.9, and able to overcome harmonic interference, of which the 3rd harmonic is less than 20%, the 5th harmonic is less than 8%, the 7th harmonic is less than 5%, the 9th harmonic is less than 4%, 11~39 The subharmonic is less than 2.5%.

[0043] The high-power AC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com