Rotary compressor

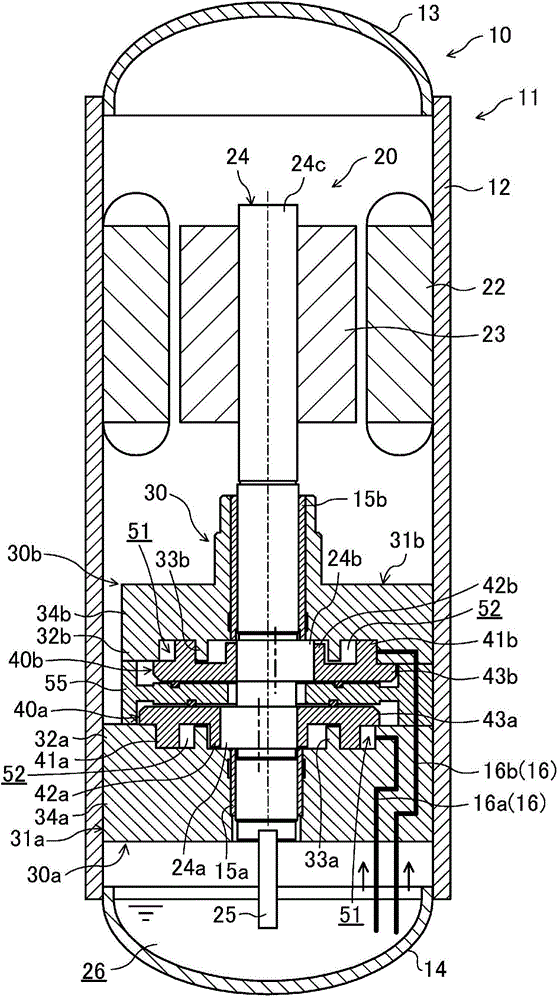

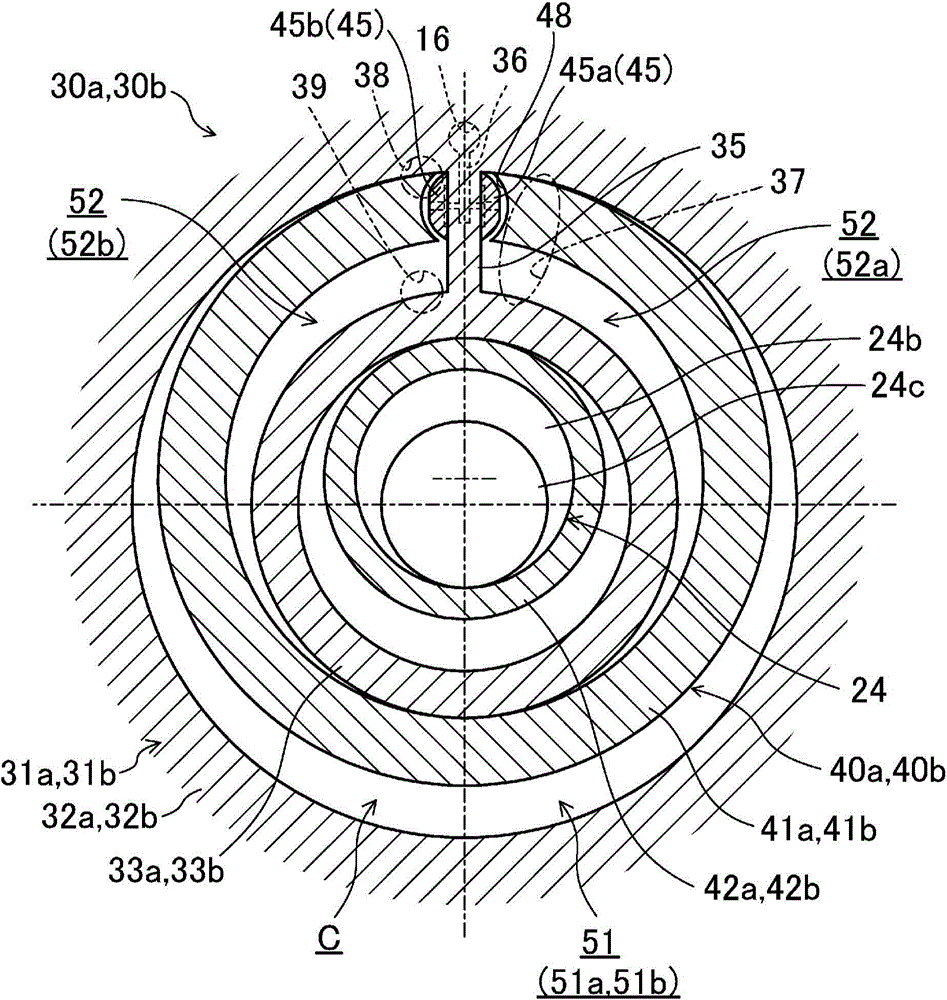

A compressor and rotary technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problem of not being able to supply oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 2-

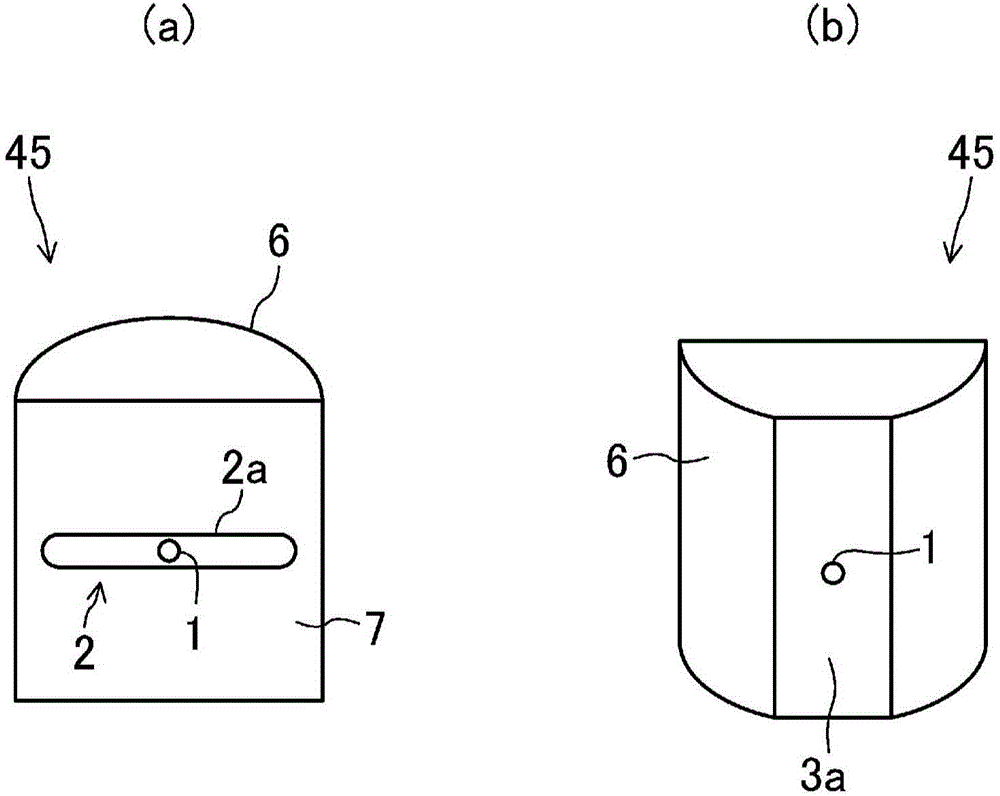

[0108] exist Figure 7 In Modification 2 of the illustrated embodiment, unlike the above-mentioned embodiment, the groove-side oil storage portion 3 of the swing bush 45 is constituted by the circumferential groove 3 extending horizontally along the curved side surface 6 of the swing bush 45 . . That is, the groove-side oil storage portion 3 of the swing bush 45 extends along the sliding direction of the swing bush 45 relative to the groove portion 48 . Both ends of the circumferential groove 3 communicate with the outside of the groove portion 48 of the pistons 40a, 40b.

[0109] According to this modification 2, since the extending direction of the groove-side oil storage portion 3 of the swing bush 45 is aligned with the moving direction of the swing bush 45, the lubricating oil in the groove-side oil storage portion 3 is smoothly drawn. to the outside of the groove portion 48 . Cooling of the sliding surface between the swing bush 45 and the groove portion 48 can be fur...

Deformed example 3-

[0113] exist Figure 8 In Modification 3 of the illustrated embodiment, unlike Modification 2 of the above-mentioned embodiment, the groove-side oil storage portion 3 of the swing bush 45 is a circumference extending horizontally along the curved side surface 6 of the swing bush 45 . To the groove 3, only one end of the circumferential groove 3 is open, and the other end is closed. As described above, even when only one end of the circumferential groove 3 is opened, the lubricating oil in the groove-side oil storage portion 3 can be smoothly discharged to the outside of the groove portion 48 .

[0114] - Modification 4 of Embodiment -

[0115] exist Figure 9 In Modification 4 of the illustrated embodiment, unlike the above-mentioned embodiment, the top of the curved side surface 6 of each swing bush 45a, 45b is cut from the end surface of the swing bush 45a, 45b to the bottom of the oil supply passage 1. near the side. As a result, only one end of the groove-side oil rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com