Tobacco grouping method based on raw material quality dynamic changes

A dynamic change and grouping method technology, applied in the direction of material inspection products, tobacco, analytical materials, etc., can solve the problems that do not involve the mechanical processing performance of different formula leaf groups, affect the accuracy and reliability of grouping results, affect the stability of cigarette formula and single Consumption and other issues, to avoid the influence of human subjective factors, the detection results are objective and accurate, and the detection method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

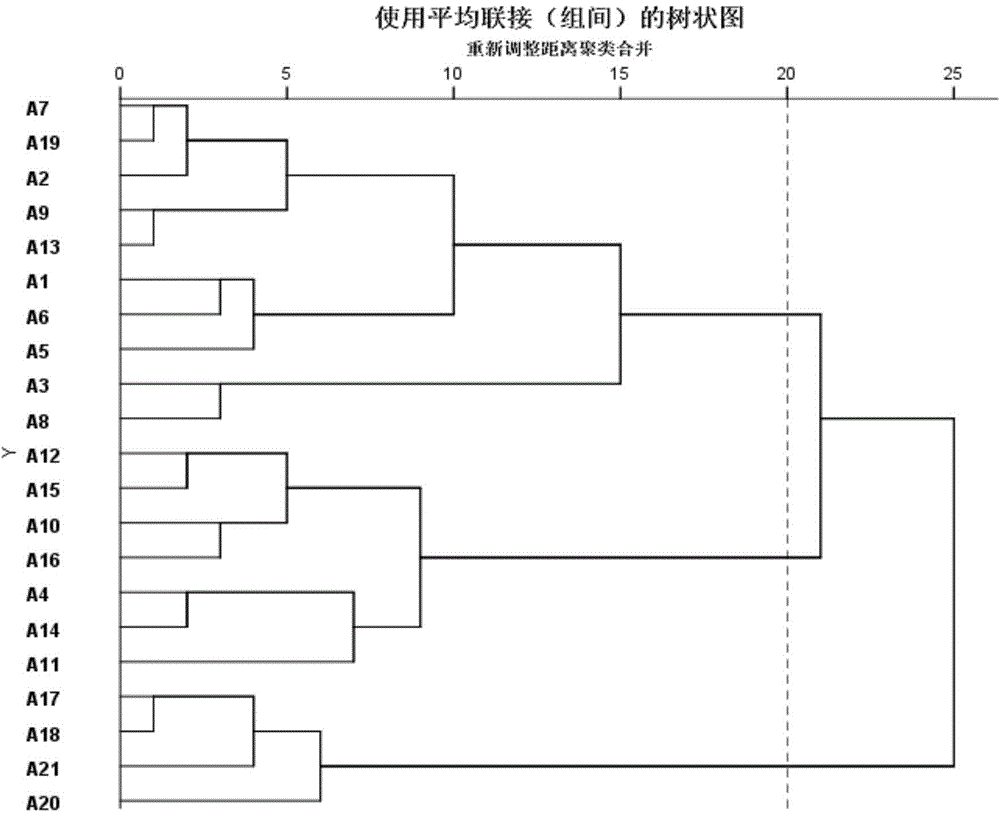

[0025] Taking Qujing Cigarette Factory as an example to illustrate the 21 formula leaf component groups of brand A cigarettes.

[0026] 1. Using the cigarette test line, carry out online moistening, storage and drying of each raw material of the grouped cigarette leaf formula according to the same processing technology, and track and sample each raw material at the entrance and drying exit of the moistening process.

[0027] 21 formula leaf groups (A1-A21) of brand A cigarettes were sampled from the raw material warehouse of Qujing Cigarette Factory of Hongyun Honghe Tobacco (Group) Co., Ltd., and multi-point samples were taken from different cigarette packs of the same leaf group. The obtained smoke samples of each leaf group were mixed evenly, and 15 kg of each sample was taken out by the method of quartering.

[0028] Moisturizing and drying: take out 500g of tobacco leaves from each raw material respectively as a sample before treatment; take out another 10kg of tobacco le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com