Cyclone gas drier

A gas drying and drying machine technology, which is used in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve problems such as human harm, environmental pollution, and corrosive equipment components, and achieve cost savings and sophisticated design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

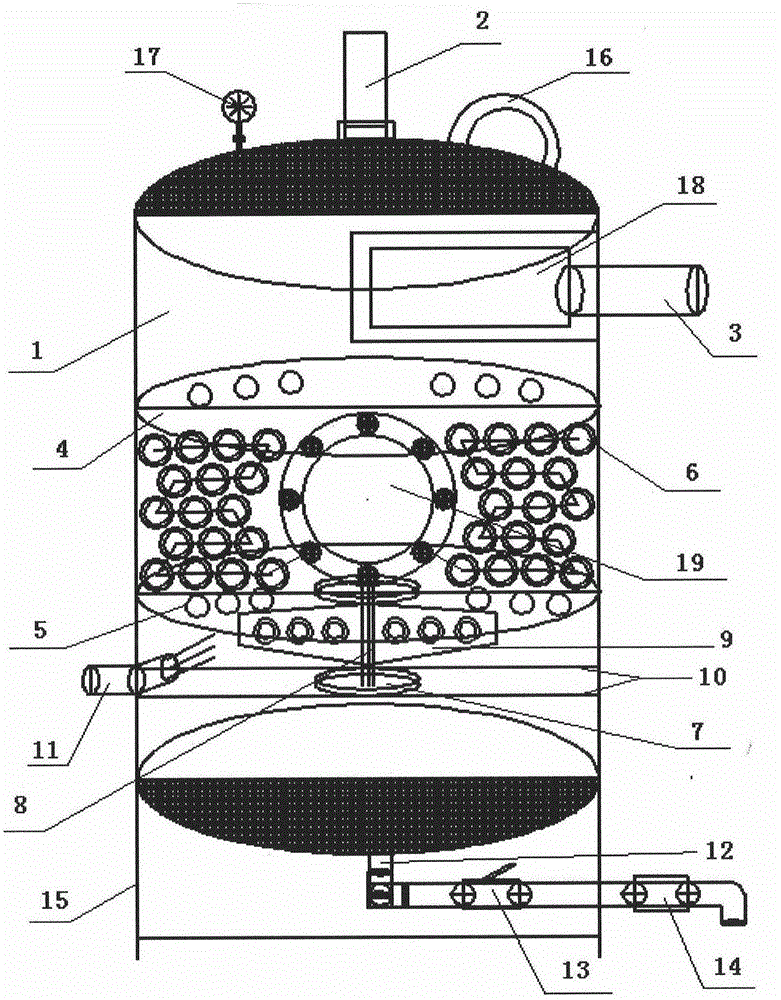

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

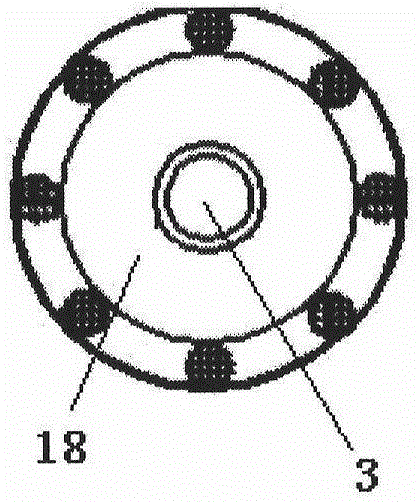

[0032] Such as figure 1 As shown, a cyclone-type gas dryer includes a tank body 1, a safety valve 2 is arranged on the top of the upper part of the tank body 1, an extended gas outlet 3 is provided on the side of the upper part of the tank body 1, and a fixed upper baffle plate is installed in the middle of the tank body 1 4 and the lower baffle 5 separate a space, and a plurality of water-absorbing balls 6 are placed inside, and the surfaces of the upper baffle 4 and the lower baffle 5 are densely covered with through holes; The ring is fixedly connected with the screw rod 8, the middle part of the screw rod 8 is connected with a fan 9, the bearing 7 at the other end of the screw rod 8 is welded on two parallel angle steels 10, and the angle steel 10 is welded on the side wall of the tank body 1, and the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com