Bottom spraying and air intake control structure of fluidized bed

A technology of control structure and fluidized bed, applied in the direction of powder suspension granulation, etc., can solve problems such as insufficient, and achieve the effect of improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

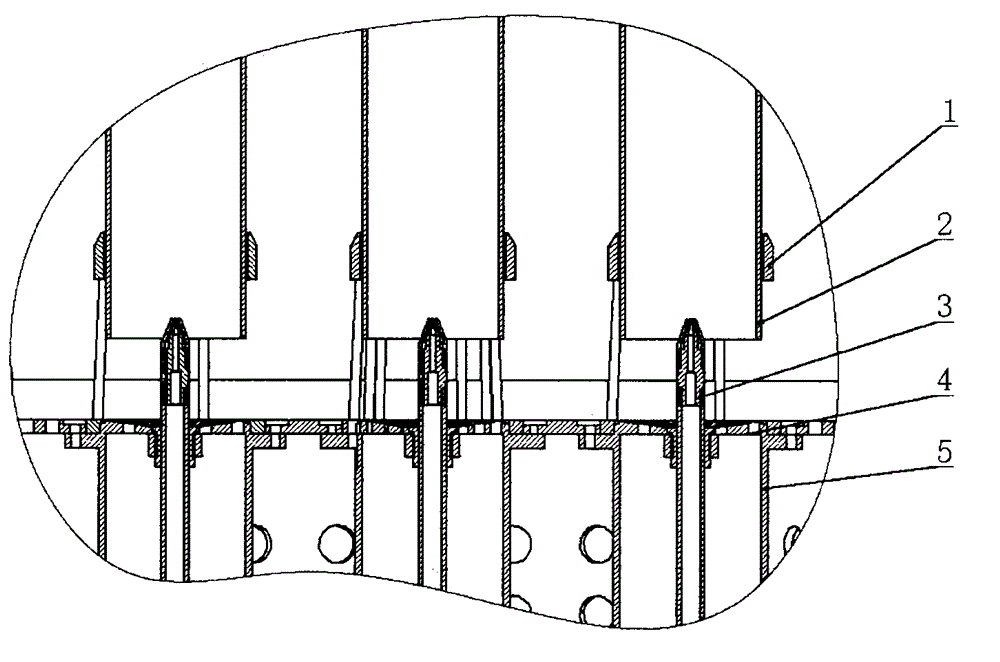

[0014] A kind of air inlet structure at the bottom of the fluidized bed of the present invention as shown in Figure 1, it comprises three spray guns, three guide tubes, three spray guns form an equilateral triangle, the opening of the air flow distribution plate inside the guide tube The porosity is 50%, and the aperture is 0.5mm. The air flow distribution plate outside the guide tube has a porosity of 40%, and the aperture is 1.0mm. Turn on two induced draft fans and set the same speed. The wind speed inside the guide tube is obvious. It is larger than the external wind speed, and this wind speed difference can be adjusted by the fan speed.

Embodiment 2

[0016] A kind of air inlet structure at the bottom of the fluidized bed of the present invention as shown in Figure 1, it comprises five spray guns, five guide tubes, five spray guns form a square and its center, the air flow distribution plate inside the guide tube The opening rate of the airflow distribution plate outside the guide tube is 70%, and the aperture is 0.7mm. The opening rate of the air distribution plate outside the guide tube is 60%, and the aperture is 1.5mm. The wind speed is obviously greater than the external wind speed, and this wind speed difference can be adjusted by the fan speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com