The Method of Quickly Installing the Spinning Tube of the Laying Machine

The technology of laying tube and laying head is applied in the field of fast installation of laying tube of laying machine, which can solve the problem of excessively large gap between laying tube and laying disc, long time for replacing laying tube, and short service life of laying tube and other problems, to achieve the effect of saving manpower, saving time for pipe replacement, and reducing wear and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

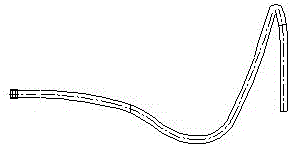

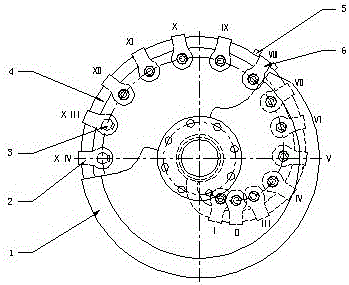

[0023] The quick installation steps of the spinning tube of the laying machine are as follows:

[0024] 1) Make every card position concentric, and choose the place with the largest curvature radius to give priority to installation

[0025] After repeated tests, it was found that the No. 8 clamp is the tail position of the deformation section as the positioning clamp, with large deformation and large curvature radius. Therefore, 14 clamps are installed in sequence from the head of the spinning tube to the tail of the spinning tube. The installation sequence is as follows: First install the first clip 6 to the position of the No. 8 card.

[0026] 2) The easy-to-deform area at the head and tail of the spinning pipe is preferentially installed

[0027] Because the head and the tail of the spinneret 4 are easily deformed, after the first clip 6 is positioned at the No. 8 clip, then the No. 1 clip will be installed on the head of the spinneret, and the No. Clip No. 14 2. Make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com