Shaving clamp for automotive transmission gear

A technology for automotive transmissions and gears, which is applied to gear teeth manufacturing devices, belts/chains/gears, gear teeth, etc. It can solve the problems of reducing gear shaving processing efficiency, cumbersome gear installation and removal operations, and improve processing efficiency. , Easy and fast disassembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

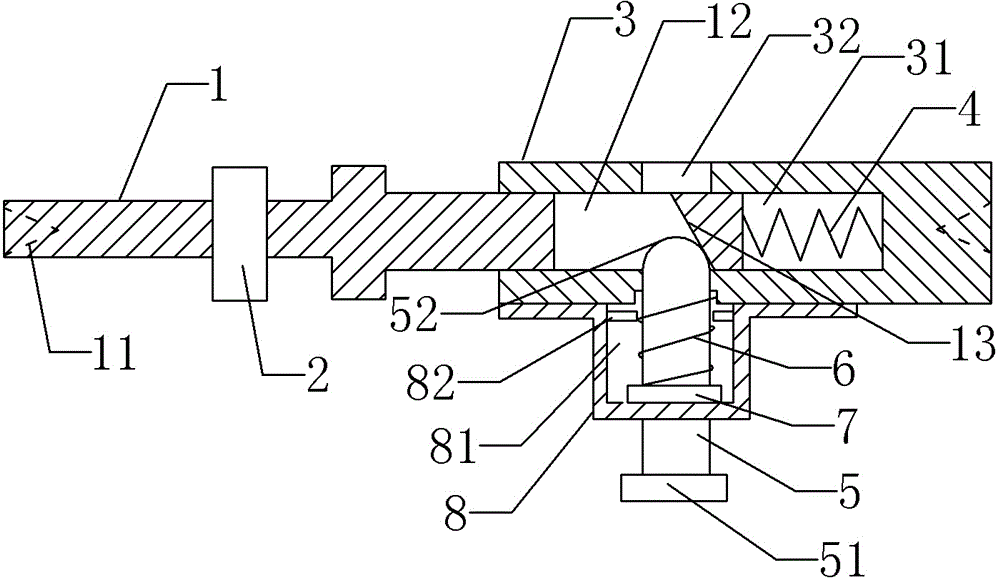

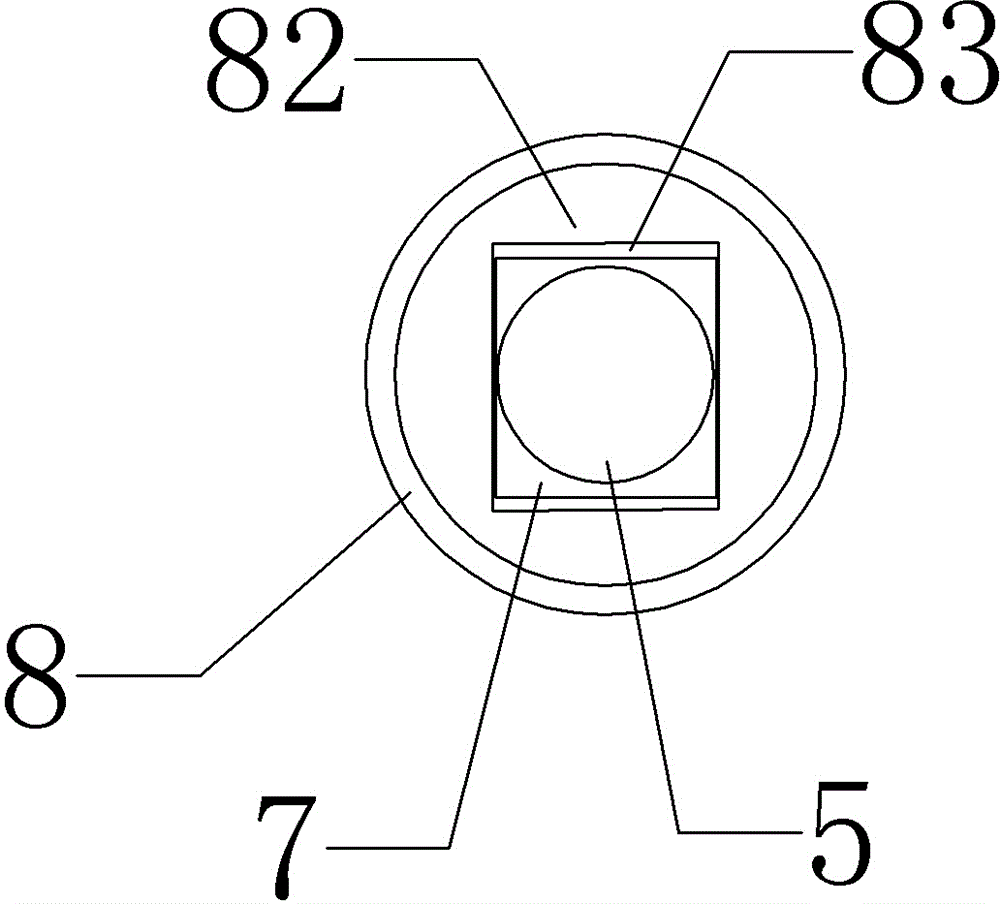

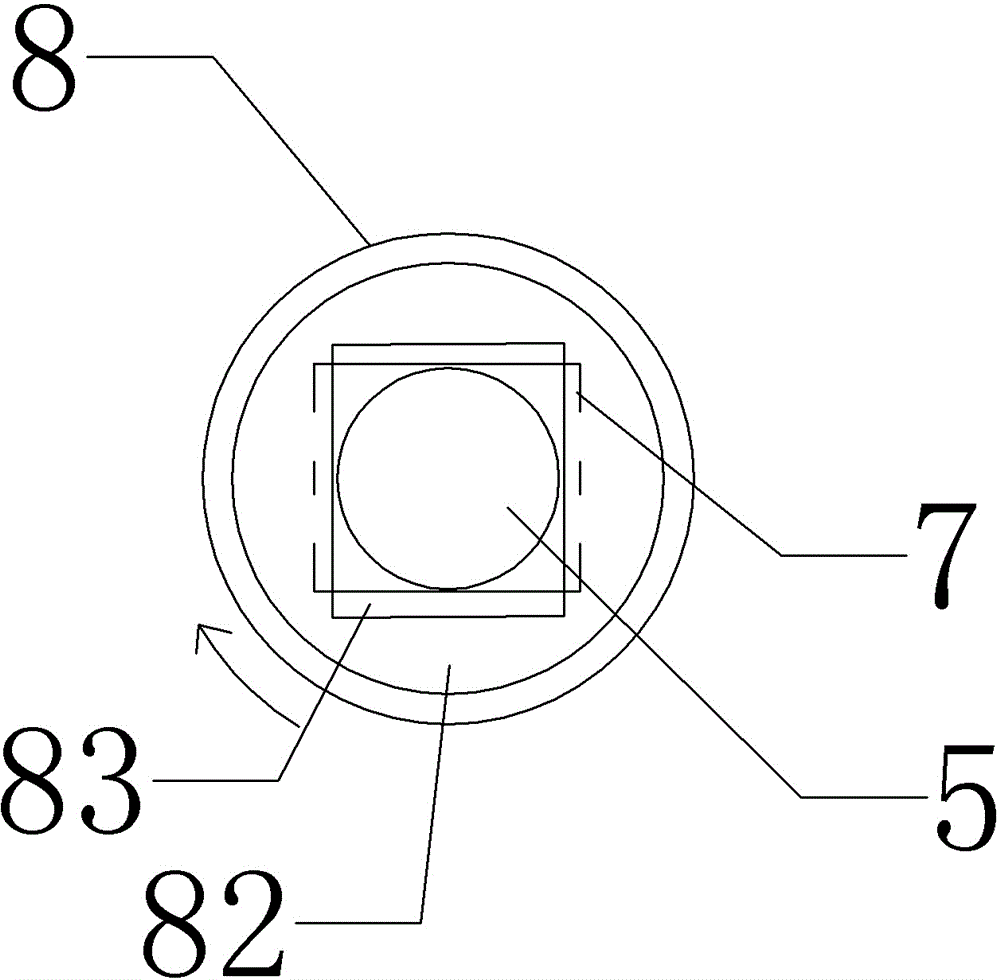

[0016] Such as figure 1 The automotive transmission gear shaving jig shown includes a stepped mandrel 1, a conical groove 11, a first elongated hole 12, an inclined hole wall 13, a ferrule 2, a connecting seat 3, a guide cavity 31, and a first through hole 32. Compression spring 4, rod-shaped button 5, button handle 51, spherical end 52, back-moving spring 6, clamping plate 7, support seat 8, support cavity 81 and chuck 82.

[0017] One end of the stepped mandrel 1 is provided with a conical groove 11, which is used for positioning the stepped mandrel at the top of the top column of the machine tool. The gear is sleeved into the small diameter section of the stepped mandrel through the conical groove 11 of the stepped mandrel 1, and one side is attached to the shaft. The shoulder is clamped by the shaft shoulder, and the ferrule 2 is set i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com