Machining method for mold with protrusion

A processing method and membrane tire technology, applied in the field of mechanical processing, can solve problems such as overcutting, large surface quality, knife sticking, and knife collision, and achieve the effects of solving processing problems, saving processing time, and ensuring geometric accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

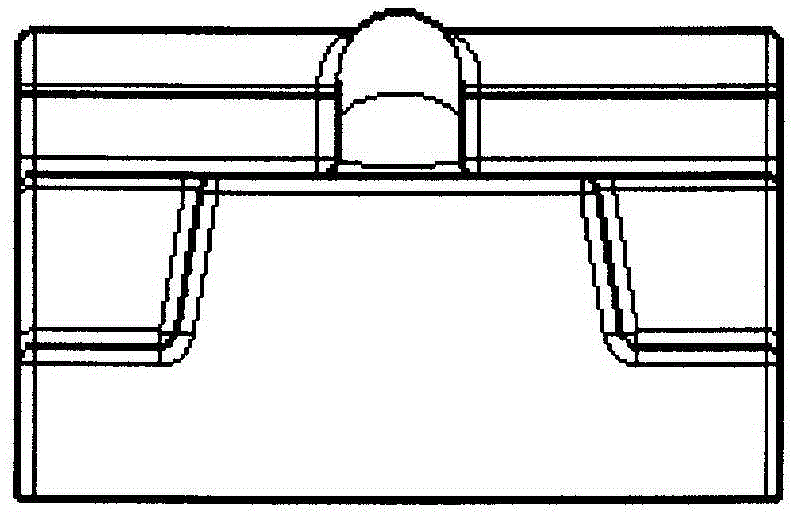

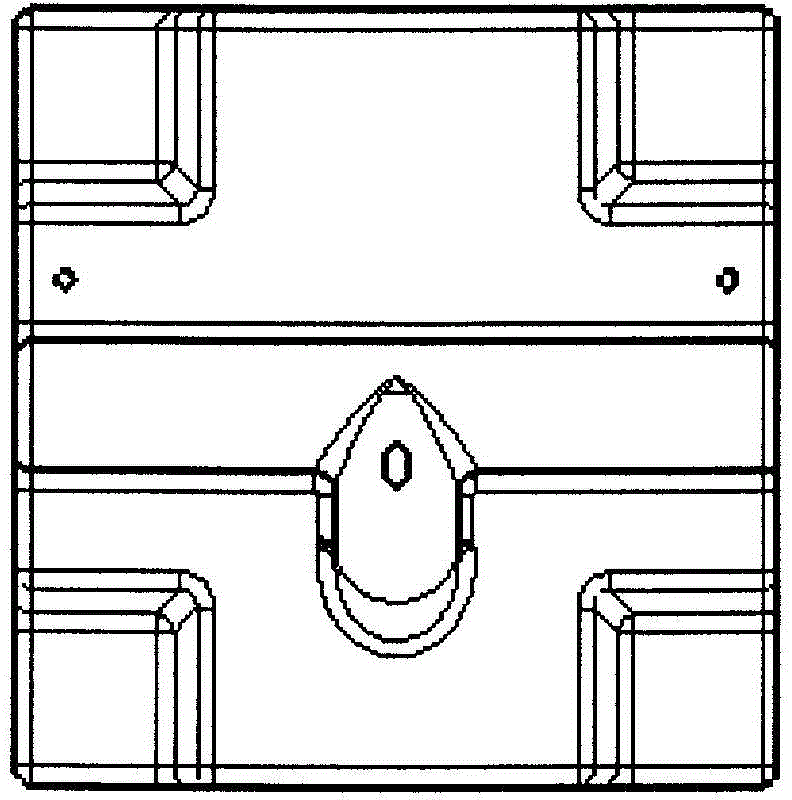

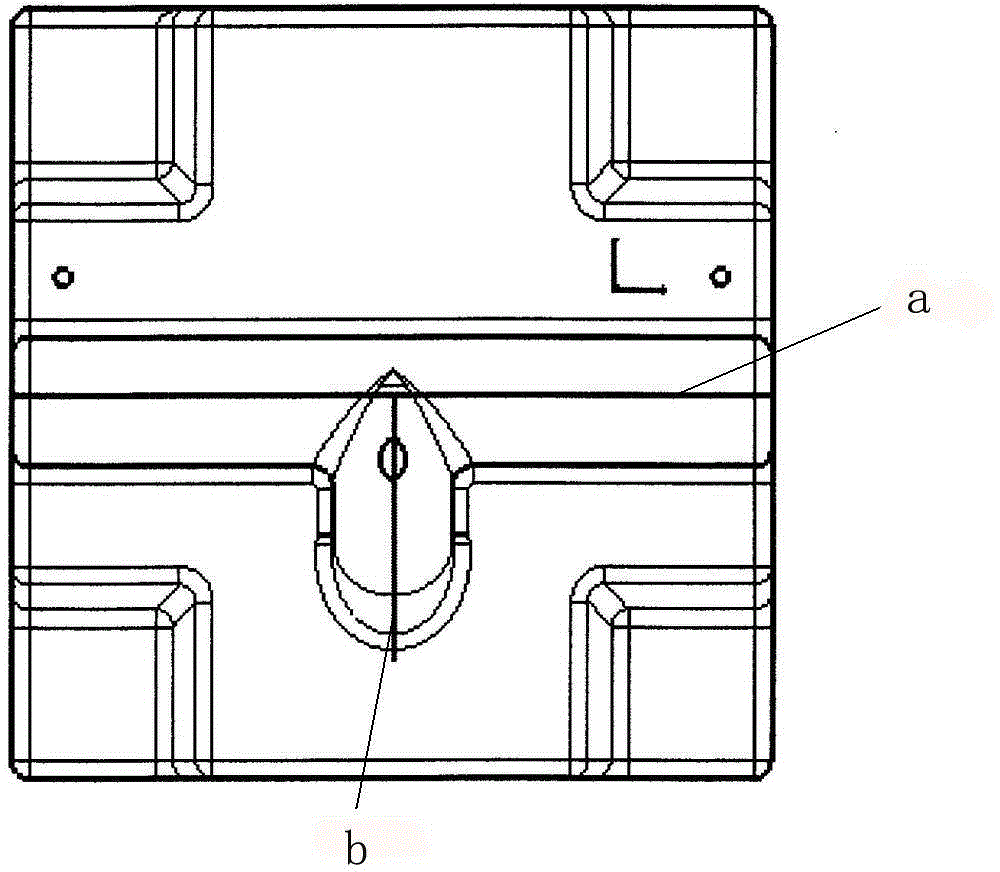

[0023] like Figure 1 to Figure 3 The processing method of the band raised membrane-like tire shown adopts the following specific steps:

[0024] (1) Processing of bottom surface 1:

[0025] (1.1) Support the flat bottom surface on the machine tool, that is, the bottom surface is upward, and support the bottom surface in a state parallel to the machine tool surface;

[0026] (1.2) Roughly plan the bottom surface;

[0027] (1.3) Finely plan the bottom surface to ensure that the flatness is 0.1-0.2mm;

[0028] (2) CNC machining of profile 2:

[0029] (2.1) Make the leading lines a and b first, such as Figure 4 As shown, then use the Contour-driven command in CATIA V5, the guide lines a and b divide the main profile into three parts, and each part is subjected to rough machining, semi-finishing machining and finishing machining respectively;

[0030] (2.2) Carry out rough machining of the profile, leaving a margin of 0.7-0.9mm;

[0031] (2.3) Carry out semi-finishing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com