Auxiliary fixed blade plate for electric hair cutter heads and fixed blade for electric hair cutter heads

A technology of fixed knife and auxiliary piece, applied in metal processing and other directions, can solve the problems of poor wear resistance, high production cost, low hardness of high carbon steel, etc., and achieve the effect of reducing production cost, prolonging service life and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

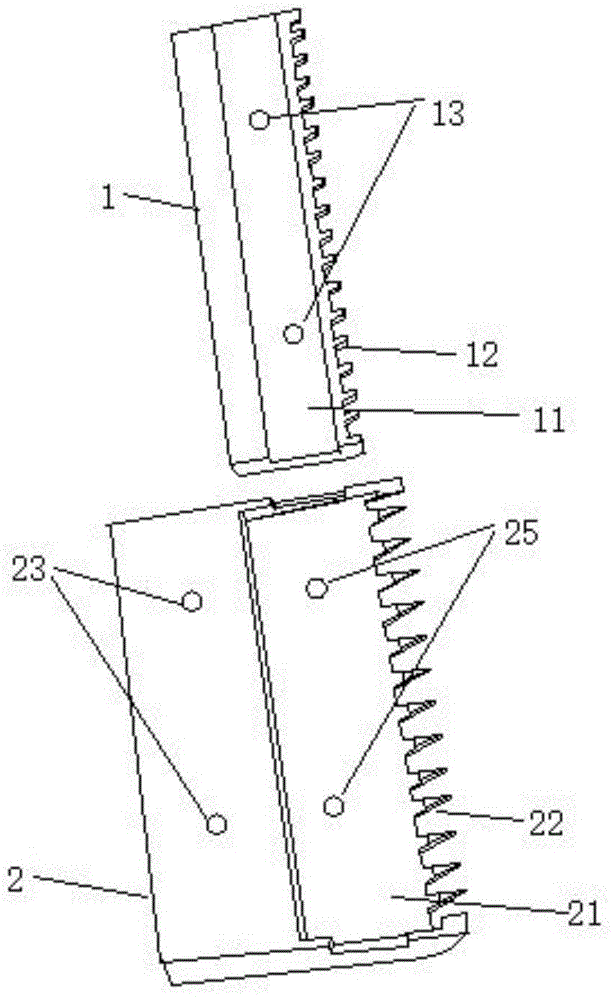

[0042] Such as figure 1 As shown, the fixed knife of the electric clipper head of this embodiment includes a fixed knife main body 2 and a fixed knife sub-piece 1 .

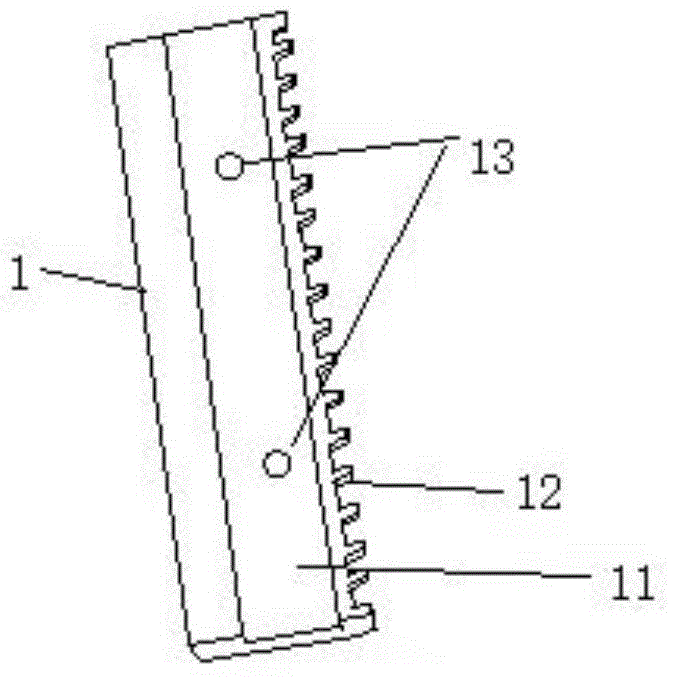

[0043] figure 2 It is a schematic diagram of the fixed knife sub-piece of the electric clipper head.

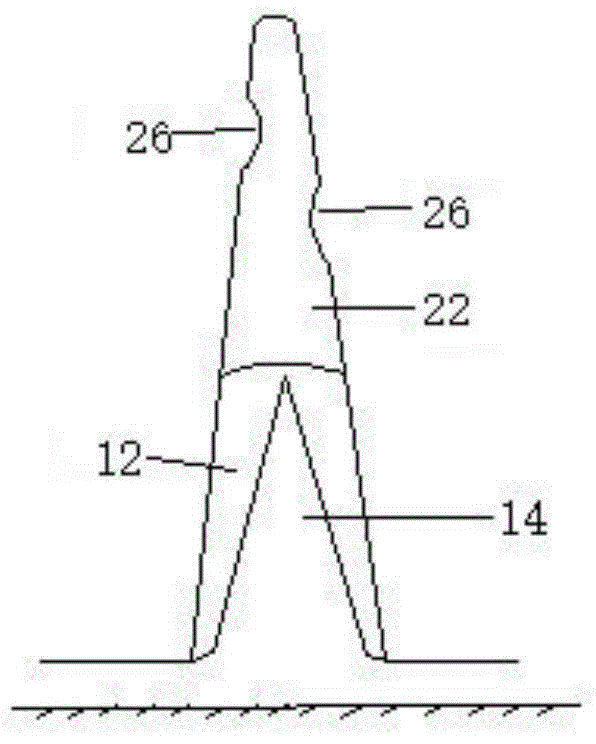

[0044] image 3 It is a partial enlarged view of the comb teeth of the electric scissors head and the fixed knife teeth that are in contact with the moving knife.

[0045] The front end of the fixed knife main body 2 has a concave platform 21 , the front end of the concave platform 21 has comb teeth 22 , and a fourth fixing hole 25 is arranged on the concave platform 21 . Comb tooth 22 is used for combing hair, and the rear portion of comb tooth 22 has section, and the front end side edge of comb tooth 22 (especially the larger comb tooth) is provided with concave anti-collision buffer zone 26 (such as image 3 As shown), when the comb teeth 22 are impacted by an external force, the comb teeth 22 are broken...

no. 2 example

[0053] Such as Figure 4 As shown, the fixed knife of the electric clipper head of this embodiment includes a fixed knife main body 2 and a fixed knife sub-piece 1 .

[0054] Figure 5 For such Figure 4 The side sectional schematic diagram of the electric clipper head fixed knife shown.

[0055] Figure 6 For such Figure 4 The schematic diagram of the fixed knife sub-piece of the electric clipper head shown.

[0056] Figure 7 For such Figure 4 The partial enlarged view of the comb teeth of the fixed knife of the electric push scissor head and the side of the fixed knife tooth that is in contact with the moving knife is shown.

[0057] The front end of fixed knife main body 2 has comb tooth 22, and comb tooth 22 is used for combing hair, and the front end side edge of comb tooth 22 (especially the larger comb tooth) is provided with concave anti-collision buffer zone (such as Figure 7 As shown), when the comb teeth 22 are impacted by an external force, the comb tee...

no. 3 example

[0071] Such as Figure 10 As shown in the exploded schematic view of the electric push scissors head, the electric push scissors head of the present embodiment includes a fixed knife composed of a fixed knife sub-piece 1 and a fixed knife main body 2, a moving knife 3 and a fastening connector (not shown in the figure). ).

[0072] The fastening connector is detachably connected to the fixed knife and the movable knife 3 through screws or screws, torsion springs and spring pressure pieces. Specifically, one end of the fastening connector is fixed to the fixed knife with screws or screws, and a torsion spring is used to And the spring pressing piece compresses the moving knife 3 by pressing the fastening connector, thereby the fixed knife and the moving knife 3 are connected and fixed. The fixed knife is the fixed knife in the first embodiment, and of course it can also be replaced with the fixed knife in the second embodiment or the first and second modified examples. Such a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap