Movable platform floor bearing support system

A technology of movable carriages and support systems, applied in the field of automobile manufacturing, which can solve problems such as inseparable from human assistance, inflexible expansion and contraction, cumbersome installation and operation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

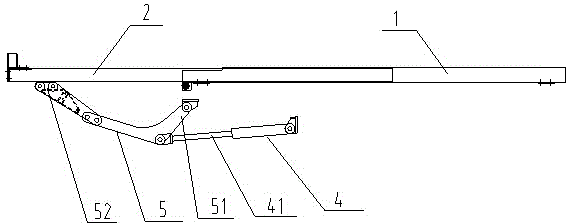

[0016] The preferred embodiment of the present invention is: a load-bearing support system for the movable carriage floor, including a plurality of transverse rails installed on the lower surface of the movable carriage floor, and a hydraulic cylinder installed under the chassis and a metal support arm connected thereto.

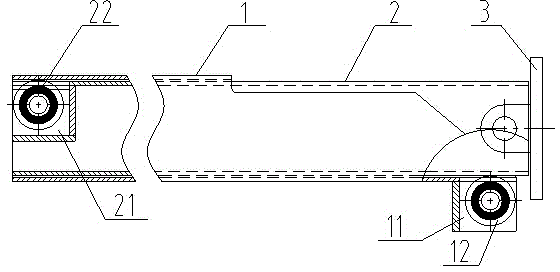

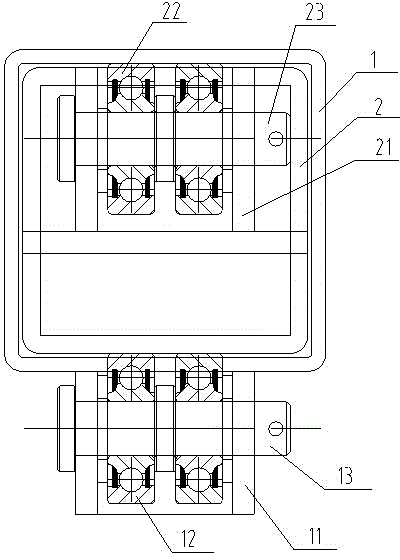

[0017] Such as figure 1 , 2 As shown, the transverse track includes a square outer sleeve 1 and a square inner tube 2, the outer sleeve 1 is a seamless steel pipe with a specification of 92mm×92mm×4mm, and the inner tube 2 is 80mm×80mm×5mm Standard seamless steel pipe, the inner tube 2 can be movably set in the outer tube 1; the bottom tube wall at the outer end of the outer tube 1 is provided with a through hole or notch, and two fixing plates 11 are welded on the bottom tube wall On both sides of the through hole or notch, two outer bearings 12 are installed between the two fixed plates 11 through the pin shaft 13, and the outer peripheral surfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com