Car steering lock case mounting bracket

A technology of steering lock shell and mounting bracket, which is applied to steering control, steering column and other directions installed on the vehicle, can solve the problems of unreasonable structural design, complex production process of steering column, single function, etc., and improve the angle adjustment function. , Improve the installation process and achieve a fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the drawings.

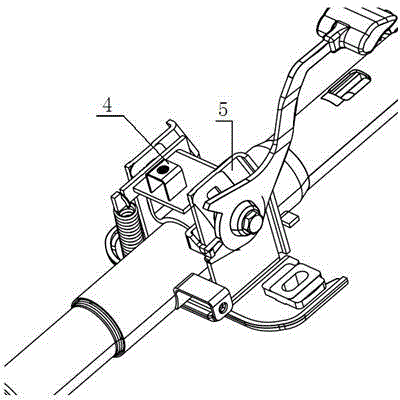

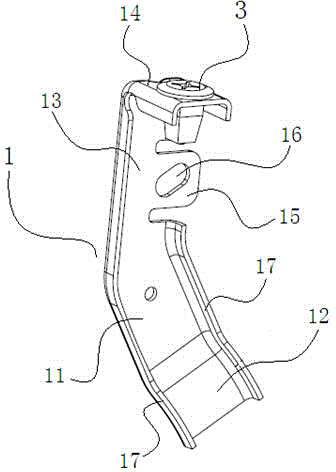

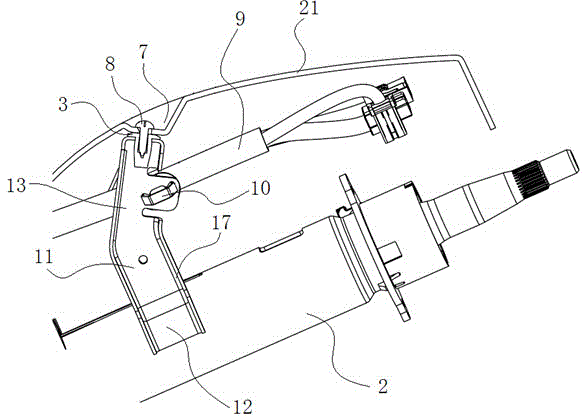

[0016] Such as image 3 , Figure 4 , Figure 5 The illustrated car steering lock housing mounting bracket includes a stamped and formed bracket body 1 with reinforced flanges 17 on the front and rear edges. The bracket body 1 consists of a vertical first support plate 11 and a first support plate 11 The arc-shaped connecting plate 12 that is connected to the lower edge and bent downward to the right, the second support plate 13 that is connected to the upper edge of the first support plate 11 and is bent upward to the right, and is connected to the upper edge of the second support plate 13 And the lock housing installation plate 14 bent to the right is formed, the arc-shaped connecting plate 12 matches and fits the outer circumferential surface of the upper cylinder 2 of the steering column, the lock housing installation plate 14 is provided with a square hole, and the square hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com