Aluminosilicate glass, method for strengthening aluminosilicate glass, and strengthened glass

A technology of aluminosilicate glass and tempered glass, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as low efficiency, unachievable combination of surface compressive stress and exchange depth, and impact on application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~25

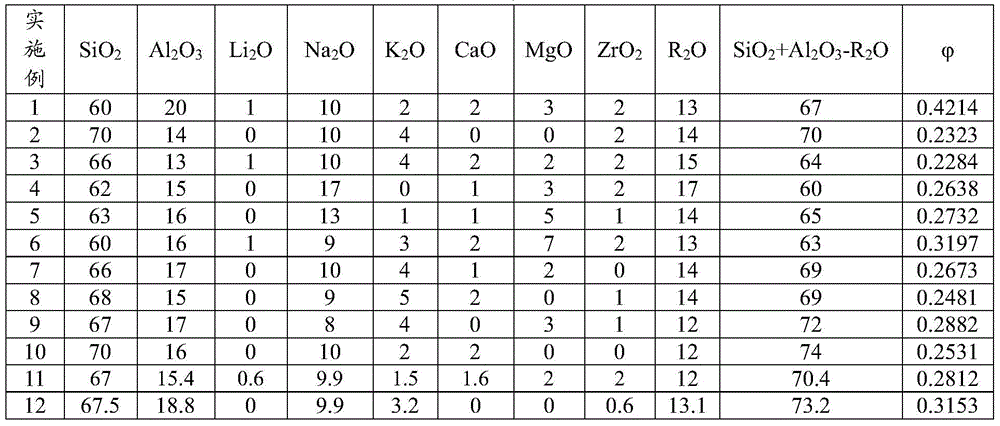

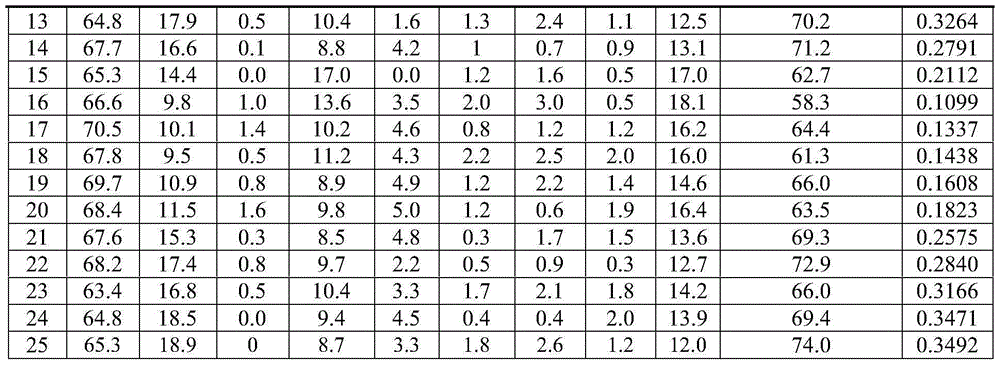

[0076] The composition of the aluminosilicate glass in Examples 1-25 is shown in Table 1. The numerical value corresponding to each raw material in Table 1 is the molar percentage of the raw material.

[0077] Table 1

[0078]

[0079]

[0080] When preparing the aluminosilicate glass of Examples 1 to 25, weigh the raw materials according to the ratio of each raw material in Table 1, transfer the weighed raw materials into a mortar and grind them thoroughly to make them evenly mixed, and then place them in In a platinum crucible. Put the platinum crucible into a silicon-molybdenum furnace and heat it to 1650°C and hold it for 3 hours for clarification, then pour the molten glass into a mold for molding, and then anneal at 650°C to obtain block glass. The bulk glass was cut into strips of 6 mm x 6 mm x 50 mm and sheets of 150 mm x 100 mm x 1.1 mm. Grind the two end faces of the strip sample again so that they are fully parallel and perpendicular to the sides.

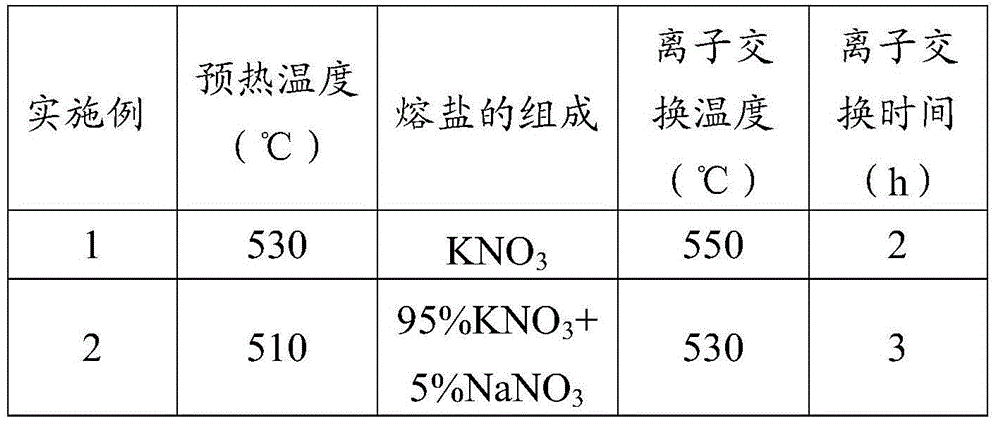

[0081]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com