Titanium-molybdenum-nickel intermediate alloy and preparation method and application thereof

An intermediate alloy, titanium-molybdenum-nickel technology, applied in the field of alloys, can solve problems such as unqualified, uneven alloy composition, and poor alloy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

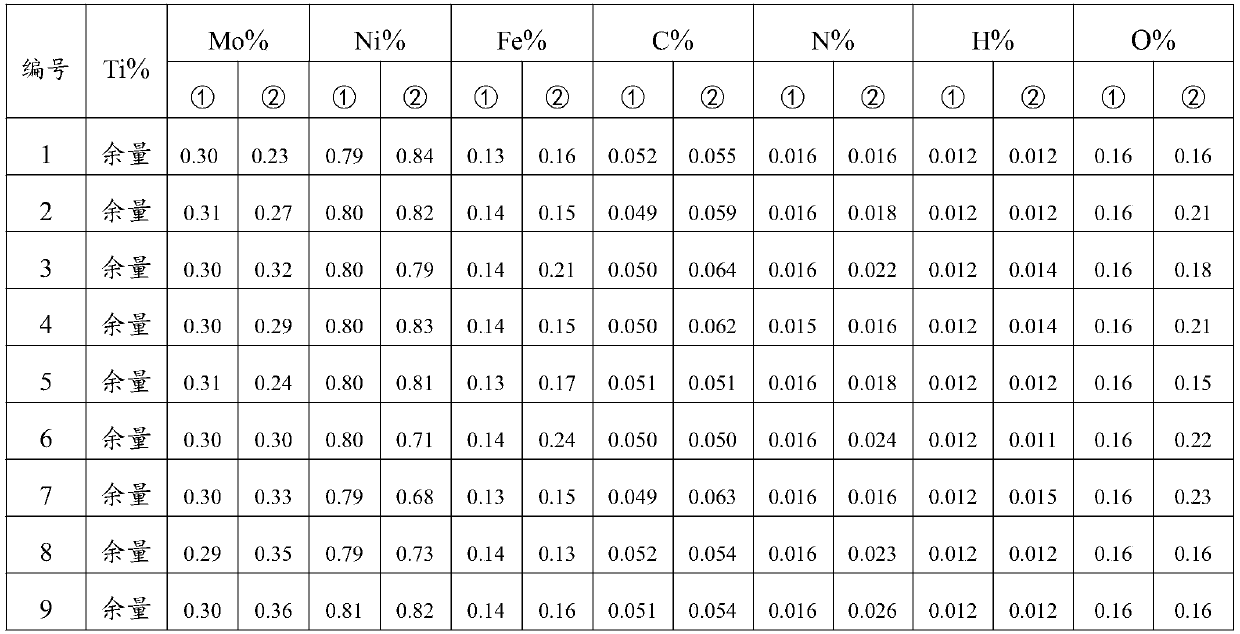

Examples

preparation example Construction

[0023] The present invention also provides the preparation method of titanium-molybdenum-nickel master alloy described in above-mentioned technical scheme, comprises the steps:

[0024] The titanium-molybdenum-nickel master alloy is obtained by mixing metal titanium, metal molybdenum and metal nickel for induction melting.

[0025] In the present invention, unless otherwise specified, all components are commercially available items well known to those skilled in the art.

[0026] In the present invention, the mass mixing ratio of the metal titanium, metal molybdenum and metal nickel is corresponding to the element content of the titanium-molybdenum-nickel master alloy described in the above-mentioned technical solution, and will not be repeated here.

[0027] The invention mixes metal titanium, metal molybdenum and metal nickel to obtain a mixed material. In the present invention, the purity of the titanium metal is preferably 99.70-100%; the titanium metal is preferably gran...

Embodiment 1

[0041] 31.50kg of titanium sponge with a purity of 99.70%, 4.50kg of molybdenum with a purity of 99.95%, and 14.00kg of nickel with a purity of 99.95% are mixed, and the raw materials are fully contacted, and loaded into an intermediate frequency vacuum induction furnace.

[0042] Start the mechanical pump and Roots pump, keep it for 15 minutes, and evacuate the intermediate frequency vacuum induction furnace. When the vacuum display shows less than 40Pa, stop vacuuming and fill with argon until the pressure gauge on the furnace reaches 1atm (that is, the flat pressure state ), stop argon filling, and start heating and melting with electricity. Start heating with the initial power of 20kW. After 20 minutes, adjust the power to 30kW. After the alloy starts to melt, adjust the power to 70kW. After the alloy is melted, increase the power to 80kW. Refined for 6 minutes, poured, cooled with the furnace for 150 minutes, and then released from the furnace to obtain a titanium-molybde...

Embodiment 2

[0045] 27.50kg of titanium sponge with a purity of 99.70%, 6.50kg of molybdenum with a purity of 99.95%, and 16.00kg of nickel with a purity of 99.95% are mixed, and the raw materials are fully contacted, and loaded into an intermediate frequency vacuum induction furnace.

[0046] Start the mechanical pump and Roots pump, keep it for 15 minutes, and evacuate the intermediate frequency vacuum induction furnace. When the vacuum display shows less than 40Pa, stop vacuuming and fill with argon until the pressure gauge on the furnace reaches 1atm (that is, the flat pressure state ), stop argon filling, and start heating and melting with electricity. Start heating with the initial power of 20kW. After 20 minutes, adjust the power to 30kW. After the alloy starts to melt, adjust the power to 70kW. After the alloy is melted, increase the power to 80kW. Refined for 5.5 minutes, poured, cooled with the furnace for 150 minutes, and then released from the furnace to obtain a titanium-molyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com