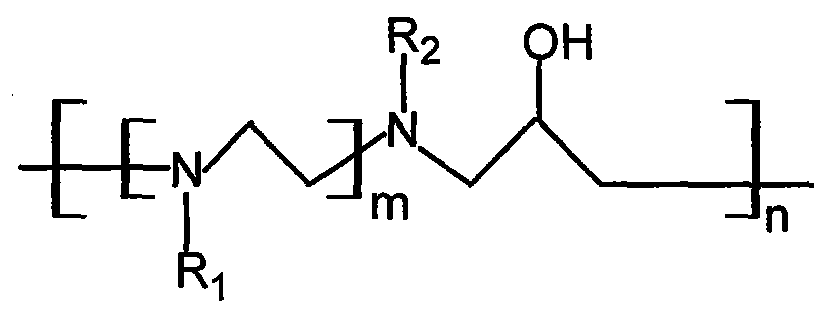

Selective water-plugging agent for super-molecular oil well and preparation method thereof

A molecular oil well and selectivity technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of poor oil-water selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] (1) Add 0.45 mol of refined β-cyclodextrin into a reaction vessel with a stirring device, and add 5.0 mol of ethanol. After mixing thoroughly, keep the temperature at 65°C for 0.5 h to form a uniform solution, and pour it into the solution with a dropping funnel. Slowly add 0.4mol epichlorohydrin dropwise to the reaction vessel, after dropping, raise the temperature of the reaction solution to 70°C-75°C, react for 3h, add 0.5mol 1-chloromethylbenzene after the reaction, and mix thoroughly;

[0007] (2) Add 0.2mol of diethylenetriamine into a reaction vessel with a stirring device, add 3.0mol of ethanol, raise the temperature to 70°C, slowly add 0.2mol of epichlorohydrin with a dropping funnel, and react at 70°C for 3h ;

[0008] (3) Slowly drop the mixture obtained in step (1) into the mixture obtained in step (2) using a dropping funnel. After the drop is complete, heat up to 90°C to 95°C and react for 4 hours to obtain the product. The average molecular weight of the...

Embodiment 2

[0010] (1) Add 0.5mol of refined β-cyclodextrin into a reaction vessel with a stirring device, add 5.0mol of ethanol, mix thoroughly, keep the temperature at 65°C for 0.5h to form a uniform solution, and pour it into the reaction vessel with a dropping funnel Slowly add 0.5 mol of epichlorohydrin into the solution, after dropping, the temperature of the reaction solution is raised to 70°C to 75°C, and react for 3.0 hours. After the reaction, add 0.5mol of 1-chloromethylbenzene and mix thoroughly;

[0011] (2) Add 0.3mol of diethylenetriamine into a reaction vessel with a stirring device, add 3.0mol of ethanol, heat up to 70°C, slowly add 0.3mol of epichlorohydrin with a dropping funnel, dropwise, and react at 70°C 3h;

[0012] (3) Slowly drop the mixture obtained in step (1) into the mixture obtained in step (2) using a dropping funnel. After the drop is complete, heat up to 90°C to 95°C and react for 4 hours to obtain the product. The average molecular weight of the product ...

Embodiment 3

[0014] (1) Add 0.55 mol of refined β-cyclodextrin into a reaction vessel with a stirring device, add 5.0 mol of ethanol, mix thoroughly, and keep the temperature at 65°C for 0.5h to form a uniform solution. Slowly add 0.6 mol of epichlorohydrin into the reaction vessel dropwise with a dropping funnel, after dropping, raise the temperature to 70°C-75°C, react for 3.0h, add 0.5mol of 1-chloromethylbenzene after the reaction, and mix thoroughly;

[0015] (2) Add 0.4mol of diethylenetriamine into a reaction vessel with a stirring device, add 3.0mol of ethanol, heat up to 70°C, slowly add 0.4mol of epichlorohydrin with a dropping funnel, dropwise, and react at 70°C 3.0h;

[0016] (3) Slowly add the mixture obtained in step (1) dropwise to the mixture obtained in step (2) with a dropping funnel, after the drop is complete, heat up to 90°C to 95°C and react for 4 hours to obtain the product. The average molecular weight of the product measured by mass spectrometry is about 21370, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com