High-toughness high-rigidity modified polypropylene material and preparation method thereof

A polypropylene material, high rigidity technology, applied in the field of high rigidity modified polypropylene material and high toughness, can solve the problems of inability to meet strength requirements, decreased rigidity and thermal deformation resistance, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

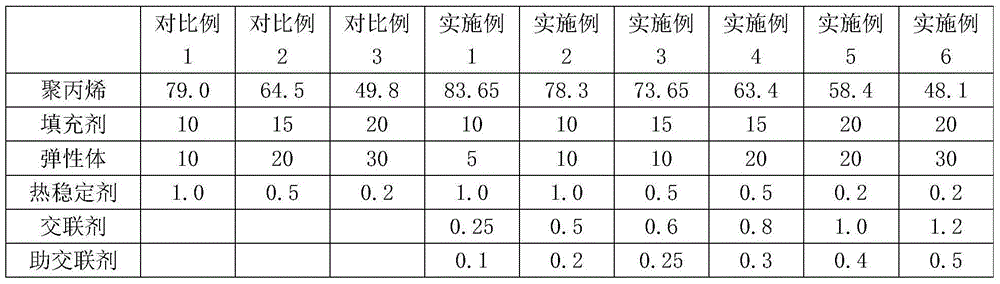

Embodiment 1

[0034] 83.65% of polypropylene, 10% of filler, 1.0% of heat stabilizer, 5.0% of elastomer, 0.25% of crosslinking agent, and 0.1% of co-crosslinking agent are dry blended in a high-speed mixer for 3-5 minutes, after which, Then it is melted and extruded in a twin-screw extruder and pelletized. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, and five zone 210-220℃, 205-215 in six zones, 200-210 in seven zones, pressure 12-18MPa.

Embodiment 2

[0036] Polypropylene 78.3%, filler 10%, heat stabilizer 1.0%, elastomer 10.0%, crosslinking agent 0.5%, and crosslinking aid 0.2% are dry blended in a high-speed mixer for 3-5 minutes, after which, Then it is melted and extruded in a twin-screw extruder and pelletized. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, and five zone 210-220℃, 205-215 in six zones, 200-210 in seven zones, pressure 12-18MPa.

Embodiment 3

[0038] The polypropylene 73.65%, filler 15%, heat stabilizer 0.5%, elastomer 10.0%, crosslinking agent 0.6%, and crosslinking aid 0.25% are dry blended in a high-speed mixer for 3-5 minutes, after which, Then it is melted and extruded in a twin-screw extruder and pelletized. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, and five zone 210-220℃, 205-215 in six zones, 200-210 in seven zones, pressure 12-18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com