Fire-watching hole cover structure for vertical flues of top-charging coke oven combustion chamber

A technology to see the fire hole cover and combustion chamber, which is applied to the heating of coke ovens, coke ovens, coke oven parts, etc., and can solve problems such as temperature disorder, production disorder of coke ovens, and poor sealing of vertical fire passages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

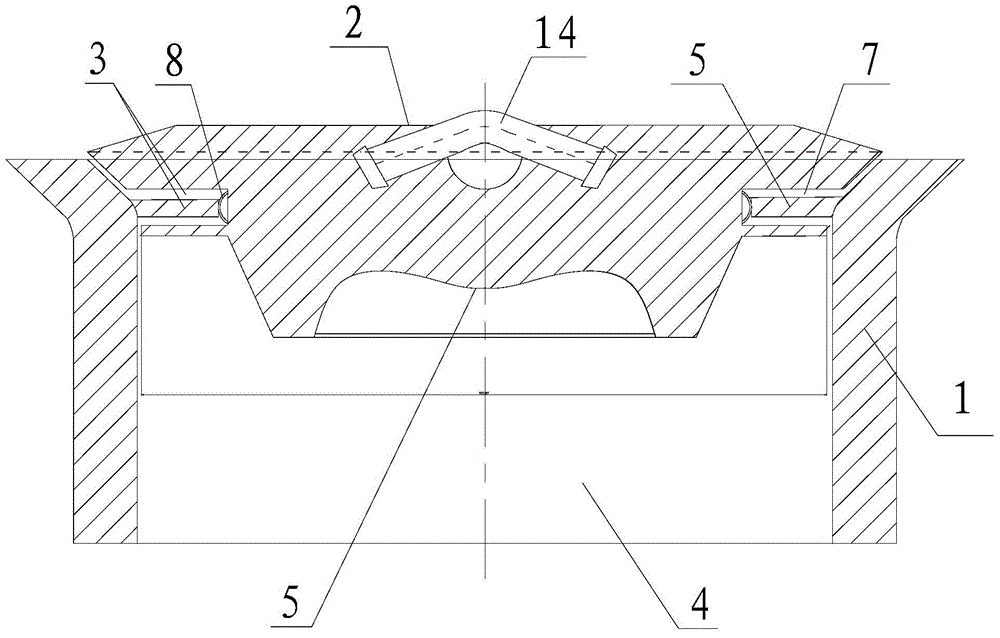

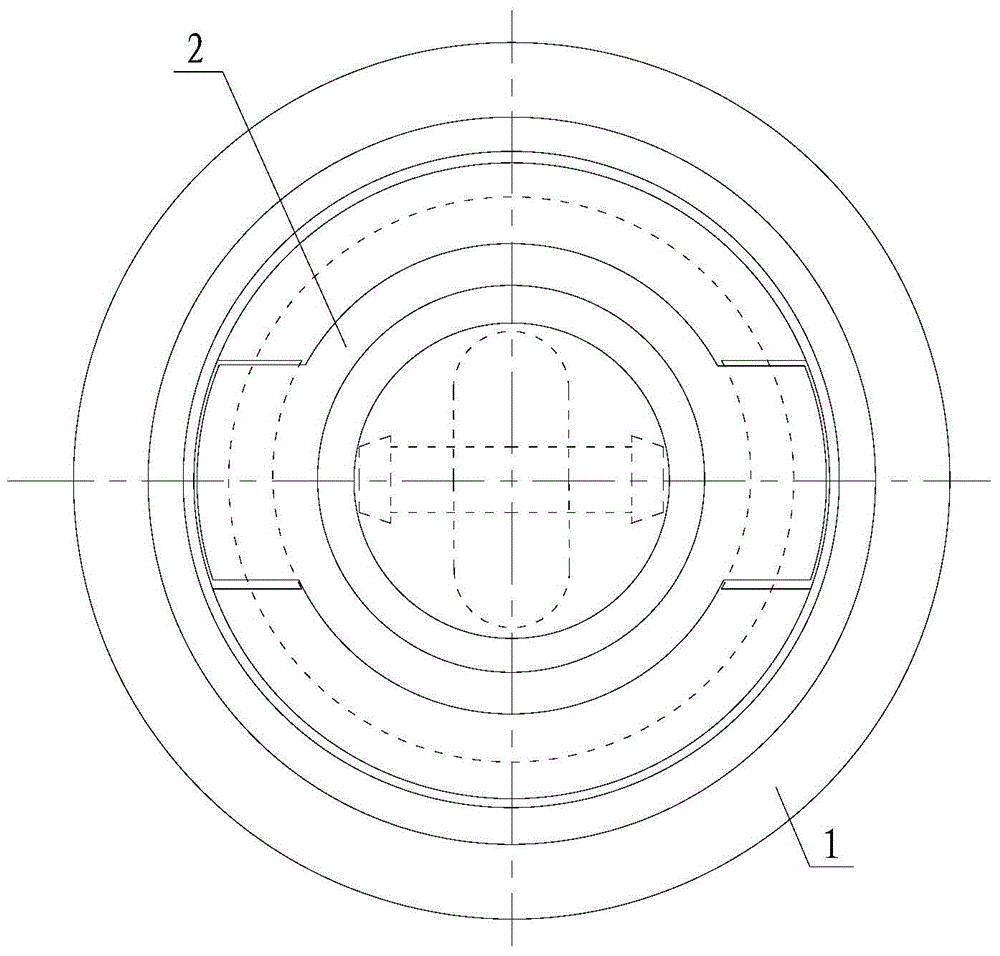

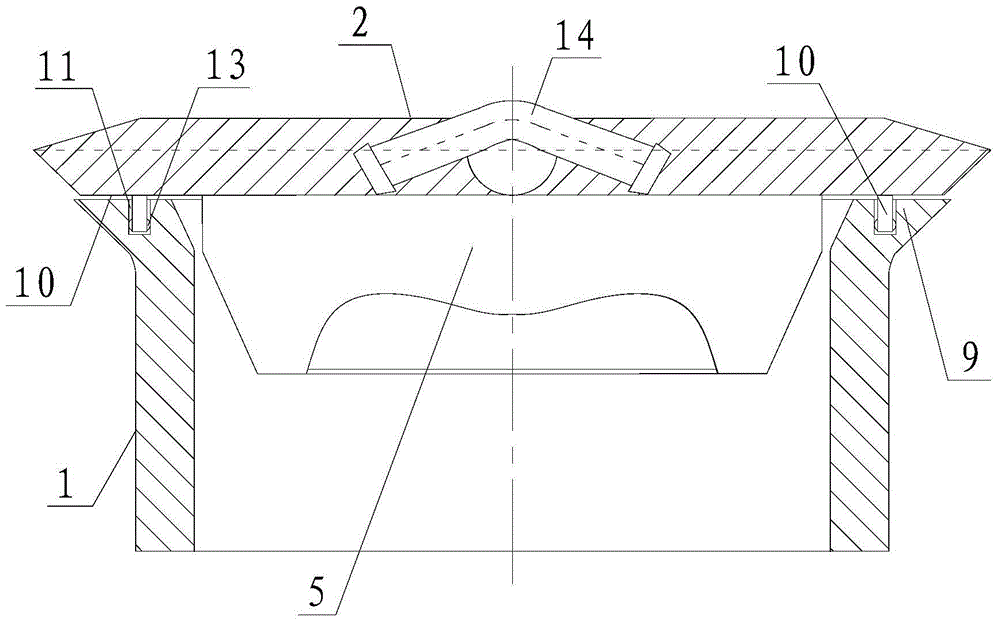

[0016] Such as figure 1 , figure 2 Shown is a kind of in the coal charging process provided by the present invention, can not cause the fire hole cover to be sucked off by the electromagnet, the fire hole cover structure that is used for the vertical fire channel of the coke oven combustion chamber of top-loading. The fire hole cover structure includes a cover base 1 and a cover body 2, and the fire hole cover structure also includes a connection locking mechanism 3, and the cover body 2 is detachably fixed by the connection locking mechanism 3 On the cover base 1, the fire viewing hole 4 on the cover base 1 is closed. Like this, the cover seat 1 and the cover body 2 constituting the firehole cover structure are detachably connected together by setting a connection locking mechanism 3 . In this way, since the cover base 1 and the cover body 2 are no longer connected to the cover base 1 by the self-weight of the cover body 2, the connection locking mechanism 3 is added to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com