Method and device for preparing chemical-mechanical pulp

A preparation device and a technology of chemical-mechanical pulp, applied in chemical/chemical-mechanical pulp, pulp bleaching, pretreatment with alkaline compounds, etc., can solve the problem of high pulping cost and achieve the effect of reducing pulping cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

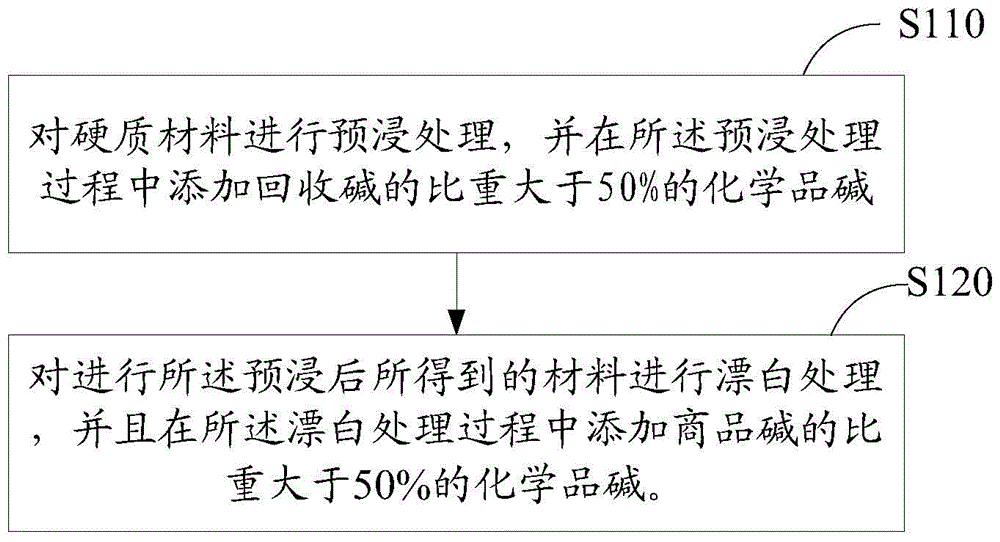

[0033] refer to figure 1 , the first embodiment of the preparation method of the chemical pulp of the present invention, comprises the following steps:

[0034] Step S110: performing pre-soaking treatment on the hard material, and adding a chemical alkali whose specific gravity is greater than 50% of the recovered alkali during the pre-soaking treatment process.

[0035] The hard material is the raw material for preparing the chemical-mechanical pulp of the present invention. The hard material is one or more of coniferous wood and hardwood.

[0036] The pre-soaking treatment refers to a process of adding pre-soaking chemicals to the hard material and soaking with it. Among them, the commonly added pre-soaking chemicals are chemical alkalis, which generally include mixed alkalis of recycled alkalis and commercial alkalis. Wherein, the recovered alkali refers to the alkali obtained through the nitric causticization reaction after the waste water produced in the pulping proces...

no. 2 approach

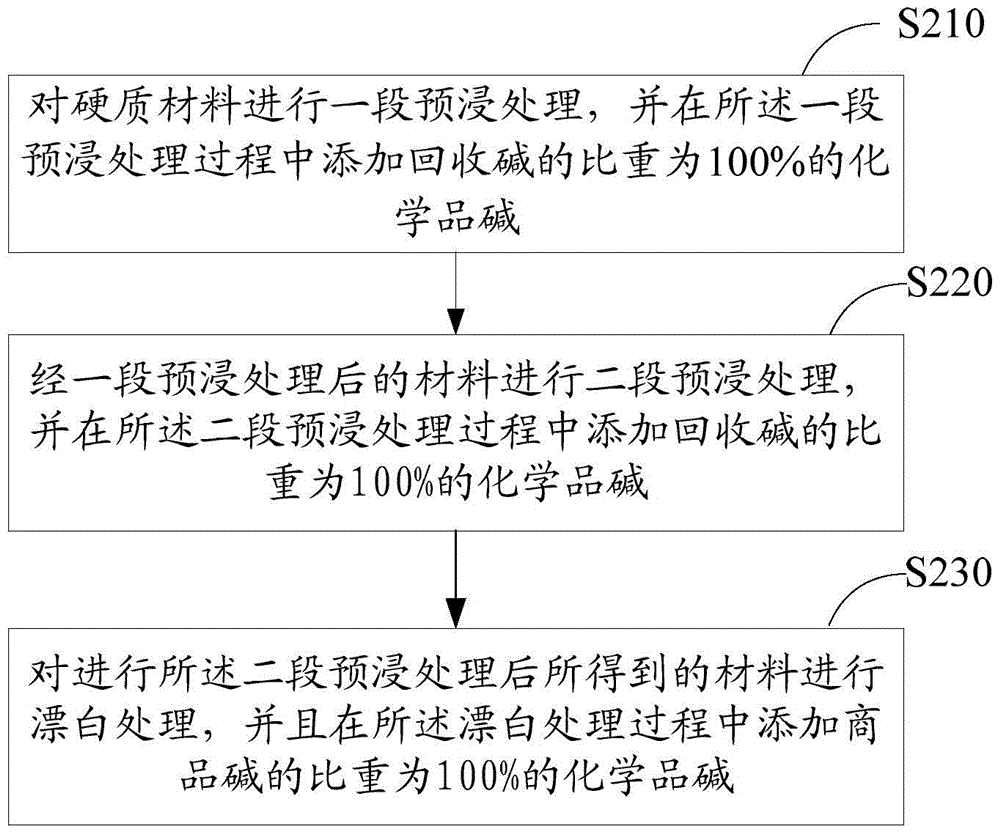

[0041] refer to figure 2 , the second embodiment of the preparation method of the chemical pulp of the present invention, comprises the following steps:

[0042] Step S210: Perform one-stage pre-soaking treatment on the hard material, and add chemical alkali whose specific gravity is 100% of recovered alkali during the one-stage pre-soaking treatment process.

[0043] The hard material is one or more of coniferous wood and broad-leaved wood, for example, one or more of acacia, pine and eucalyptus can be used, and the present embodiment adopts acacia, pine and eucalyptus Mixed wood chips, wherein the ratio of acacia: pine: eucalyptus is in the range of 60-80:10-30:0-10.

[0044] During the first stage of presoaking treatment, the added proportion of the recovered alkali is 100%, and the added amount of the recovered alkali is 20kg / adt-22kg / adt.

[0045] Step S220: The material after the first-stage pre-soaking treatment is subjected to the second-stage pre-soaking treatment,...

Embodiment 1

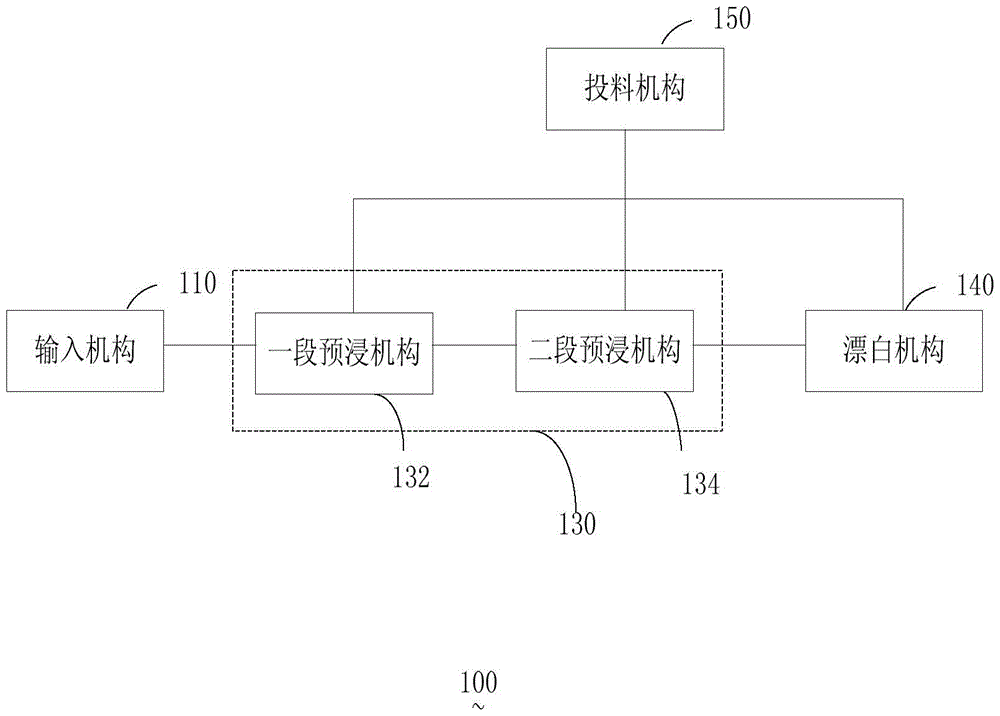

[0066] The input mechanism conveys mixed wood chips containing acacia wood, pine wood and eucalyptus wood, wherein the ratio of acacia wood: pine wood: eucalyptus wood is 70:20:10.

[0067] A section of pretreatment mechanism, such as a wood chip tearing machine, performs extrusion and tearing treatment on the hard material. Wherein the torque of the wood chip tearing machine is set to 155kN·m.

[0068] The hard material that has been squeezed and torn by the pretreatment mechanism enters a stage of prepreg in the prepreg mechanism for a stage of prepreg treatment. During the process of the stage of prepreg treatment, the feeding mechanism feeds the The recovered alkali with a specific gravity of 100% is added to the pre-soaking mechanism, and the added amount of the recovered alkali is 21kg / adt.

[0069] The hard material after one-stage prepreg treatment is sent to the second-stage pretreatment mechanism, such as a wood chip tearing machine for extrusion and tearing, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com