Heat insulation culvert pipe system between internal lines in railway station and burial and construction method

A technology for railway stations and construction methods, which is applied in pipeline laying and maintenance, artificial islands, water conservancy projects, etc., can solve the problems of high labor intensity, low water replenishment efficiency, and inability to obtain heat preservation, and achieves improved water supply capacity and work efficiency. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

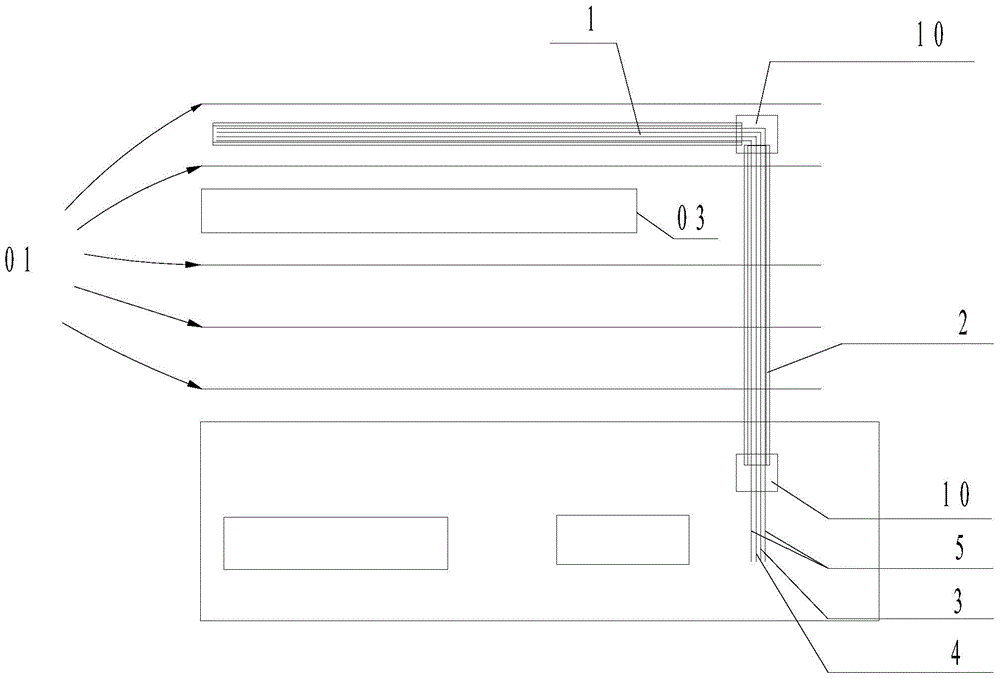

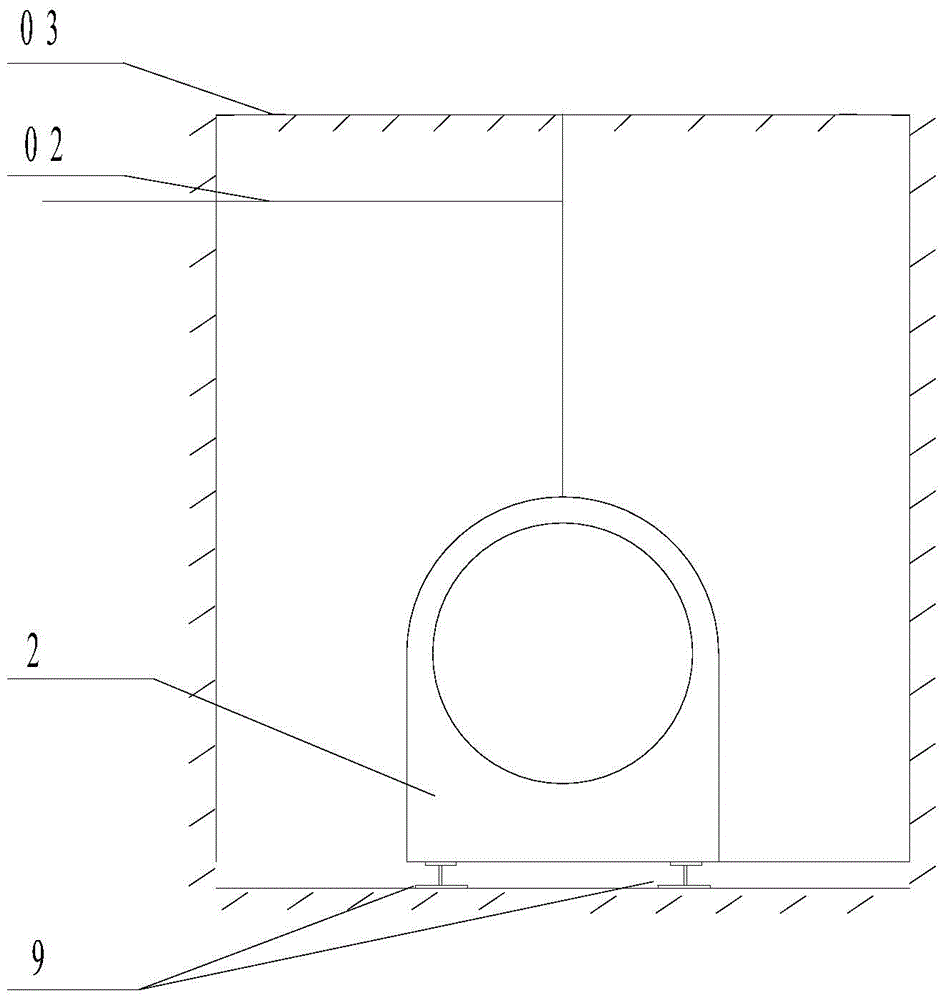

[0032] Such as Figure 1-3 As shown, a thermal insulation culvert pipe system between lines in a railway station includes a thermal insulation culvert pipe 1 and a protective culvert pipe 2. The thermal insulation culvert pipe 1 is buried below two adjacent existing lines 01 and is parallel to the existing line 01. The protective culvert pipe 2 spans Several existing lines 01 are buried below, one end of the insulation culvert pipe 1 is vertically connected to the protection culvert pipe 2, and the other end of the insulation culvert pipe 1 is connected to the water supply platform 03; the insulation culvert pipe 1 and the protection culvert pipe 2 are equipped with a water supply pipeline 3 and a drainage pipeline 4 , heating pipeline 5, wherein the water supply pipeline 3 and the drainage pipeline 4 are connected to the municipal pipe network, and the heating pipeline 5 includes two pipelines, one supply and one outlet, and are connected to the boiler room. For example, the h...

Embodiment 2

[0037] The present invention also discloses a construction method for burying the thermal insulation culvert pipe system between lines in railway stations, including the above-mentioned thermal insulation culvert pipe system for line parts in railway stations, including the following construction steps:

[0038] Step 1. Erect D-shaped beams, protect the excavation site, and lift the existing line 01 in the installation area through the D-shaped beams;

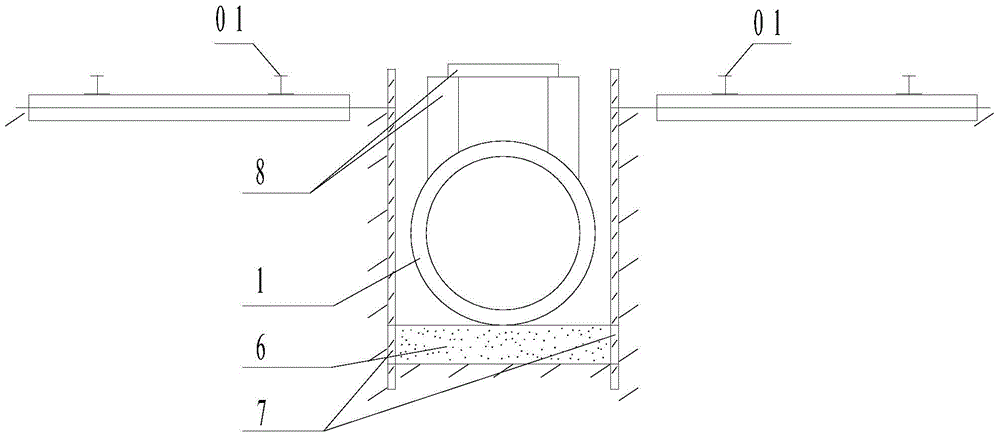

[0039] Step 2, protect the culvert pipe 2 jacking, such as Figure 4 As shown, excavate the working pit 10, pour a C15 concrete cushion with a thickness not less than 100mm at the bottom of the working pit 10, lay the jacking guide rail 9 in the working pit 10, place the protective culvert pipe 2 on the jacking guide rail 9, and use two hydraulic The jack is jacked in one direction until the jacking of the protective culvert pipe 2 is completed;

[0040] Among them, when the protection culvert pipe 2 is jacked, the internal ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com