Construction method of hollow transparent plate roof system with special-shaped curved surface

A technology of roofing system and special-shaped curved surface, which is applied in the direction of roofing, roofing, and roofing cladding using flat/curved panels, which can solve the problem of poor shape plasticity, difficulty in thermal insulation performance and UV resistance, and difficulty in meeting architectural aesthetic requirements and other issues, to achieve excellent lighting effects, save energy costs, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

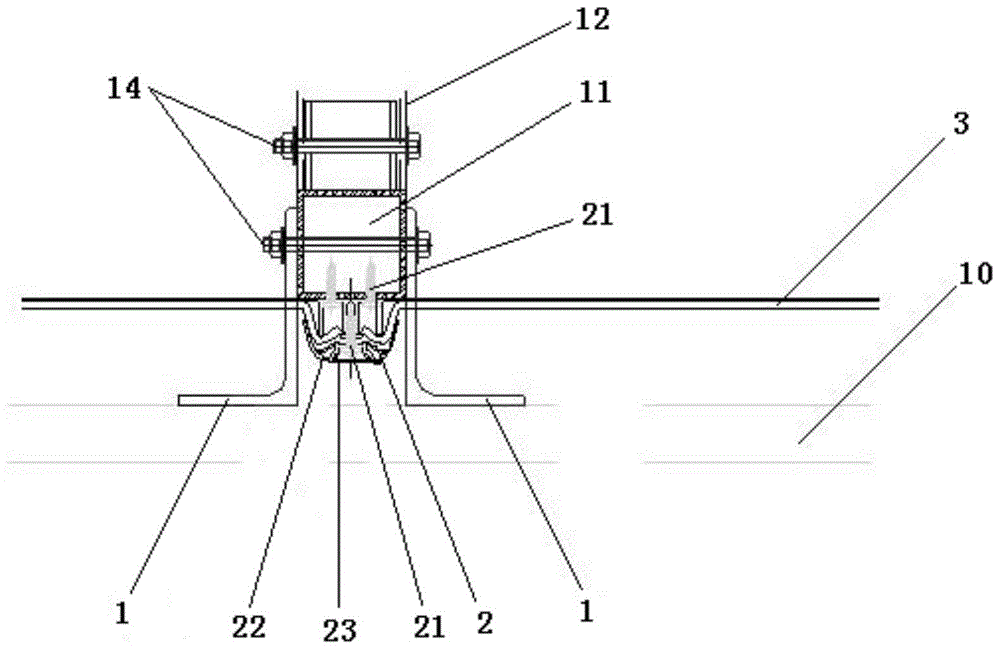

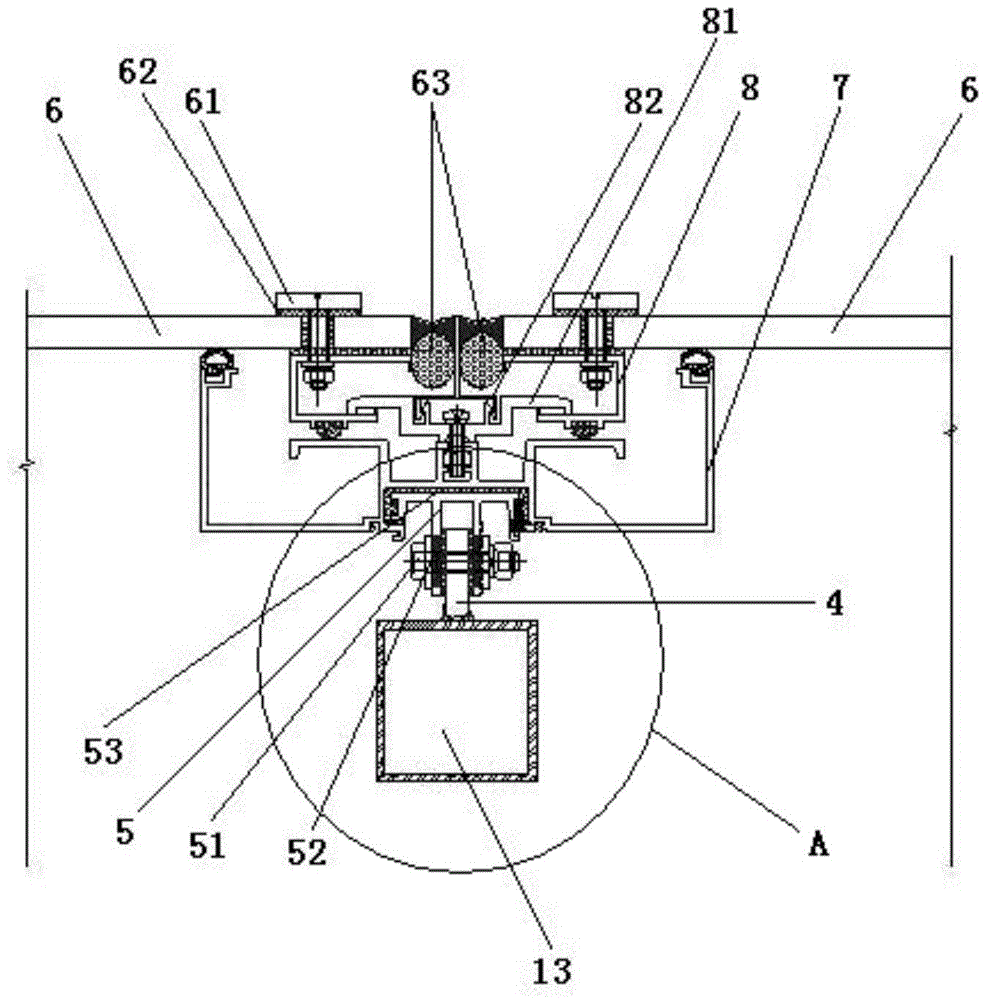

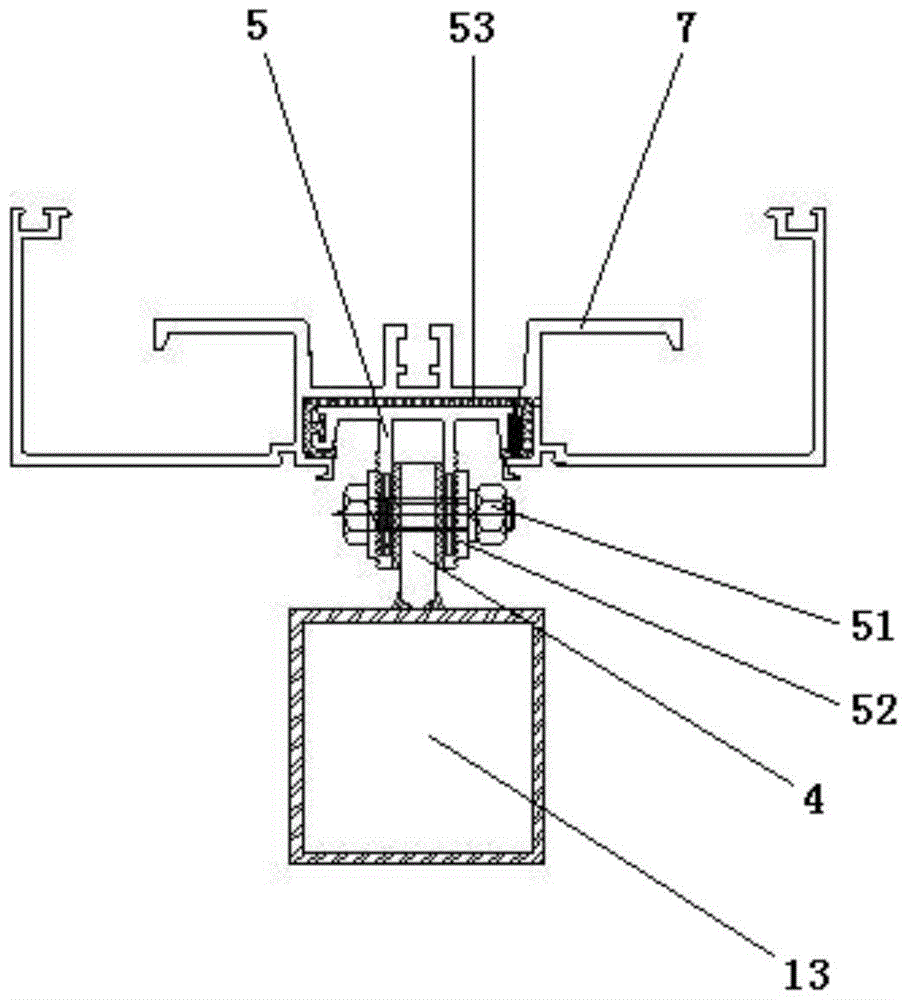

[0053] The following in conjunction with the accompanying drawings of the manual figure 1 , figure 2 , image 3 and Figure 4 , the present invention will be further described.

[0054] The construction method of the special-shaped curved surface hollow transparent board roof system provided by the present invention includes the following steps:

[0055] Step 1: Measure and set out the wire;

[0056] According to the work surface submitted by the steel structure, pop up the positioning line on the corresponding position of the connection point of the roof system that needs to be built with a special-shaped curved surface structure on the steel structure;

[0057] Step 2: Install galvanized corner code 1;

[0058] On the main beam 10 of the steel structure, install the paired galvanized corner codes 1 for clamping and fixing the lower floor square channel 11 at equal intervals. The galvanized corner codes 1 are welded and connected with the main beam 10 of the steel struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com