Installation structure of scaffold

A technology for installing structures and scaffolding, which is applied in the connection of scaffolding, housing structure support, housing structure support, etc., can solve the problems of difficult connecting rod fixation, high labor intensity, trouble, etc., and achieves fast and convenient installation, simple structure, and prevents vertical The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

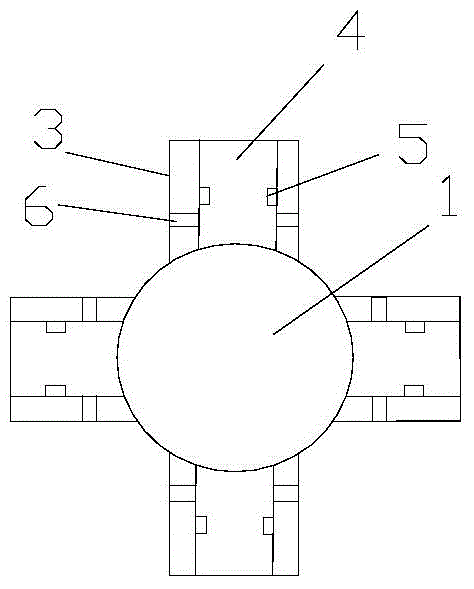

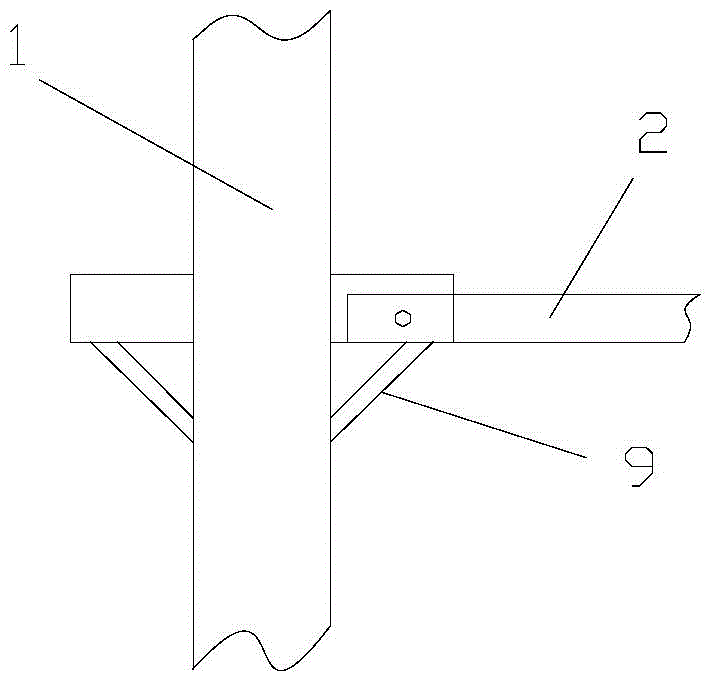

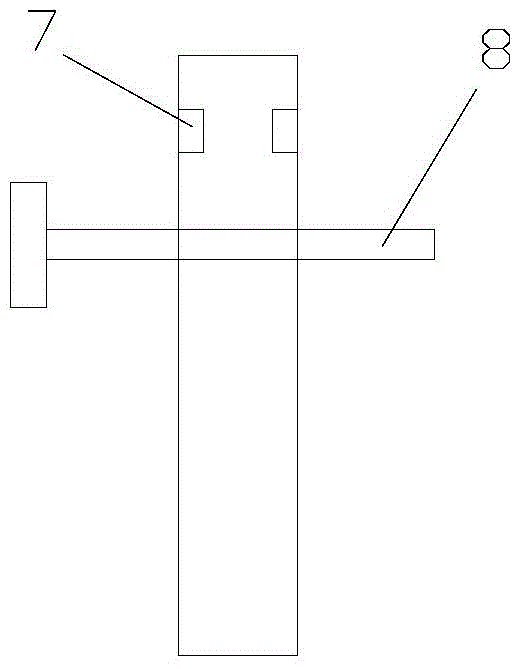

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1 to Figure 3 As shown, a scaffold installation structure includes a cross bar 1 and a vertical bar 2, four supporting plates 3 are welded around the vertical bar, and brackets 4 are provided on the supporting plates, and the two brackets of the brackets are A side wall is provided with a strip-shaped stop block 5 and a pin hole 6, the cross-section of the cross bar is square, and both sides of the end of the cross bar are provided with a stop slot that matches the stop block. 7 and the positioning pin 8 matched with the pin hole. When in use, the front end of the cross bar is put down along the limit block, that is, falls into the bracket, and then the positioning pin is inserted into the pin hole of the cross bar and the pin hole on the supporting plate, thereby locking the cross bar on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com