Novel automobile parallel flow condenser channel

A parallel flow, condenser technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem of not fully utilizing the heat exchange capacity of the condenser, and achieve the goal of improving heat exchange capacity and heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

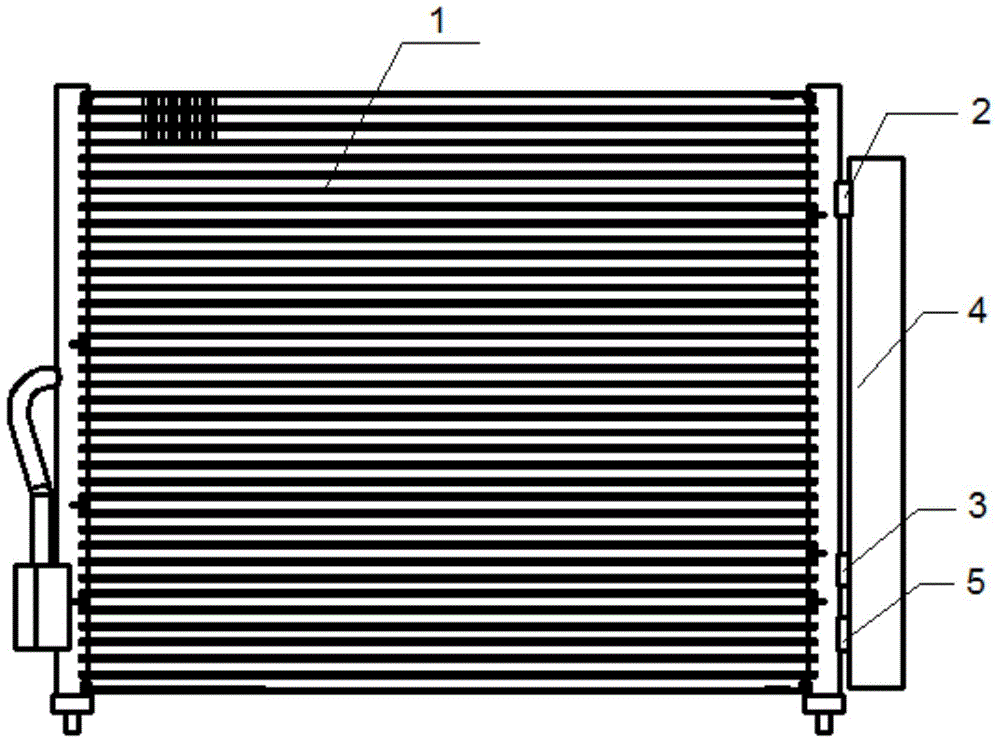

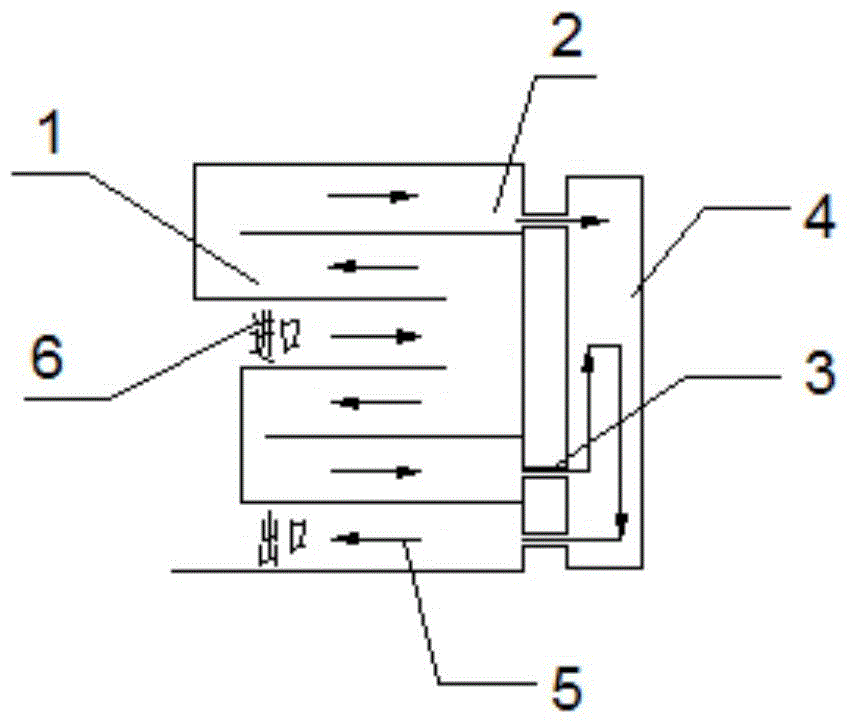

[0016] figure 1 and figure 2 It is a schematic structural diagram of the flow channel of a novel parallel flow condenser for automobiles of the present invention, including a header 1, an inlet 6 for the inflow of the refrigerant is arranged near the middle of the header 1, and the upper and lower ends of the header 1 are respectively provided with a refrigerant supply. Outgoing upper outlet 2 and lower outlet 3.

[0017] It also includes a transition pipe 4, and both the upper outlet 2 and the lower outlet 3 communicate with the transition pipe 4; Half of the flat tubes at the inlet 6 extend to the upper outlet 2 and the lower outlet 3 respectively. The flat tube extends in an "S" shape.

[0018] In order to further verify the heat exchange effect, rapid prototyping parts were made according to the above flow channels and the prior art flow channels, respectively, and the following data were obtained as a reference after performance testing:

[0019]

[0020] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com