Condenser with built-in oil separator

An oil separator and condenser technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the increased difficulty in processing and manufacturing refrigeration oil filling equipment, the increase in the external dimensions of refrigeration and air-conditioning units, and product market competition. It can reduce the problem of force weakening, and achieve the effect of reducing external leakage points, reducing heat exchange dead ends, and reducing welding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

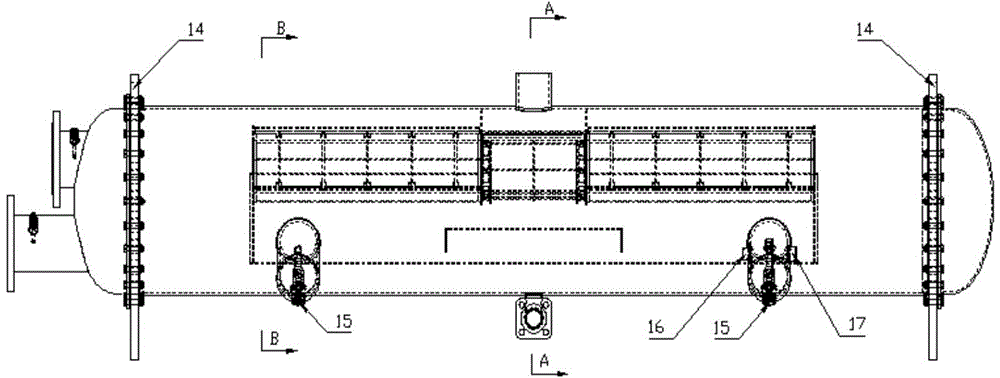

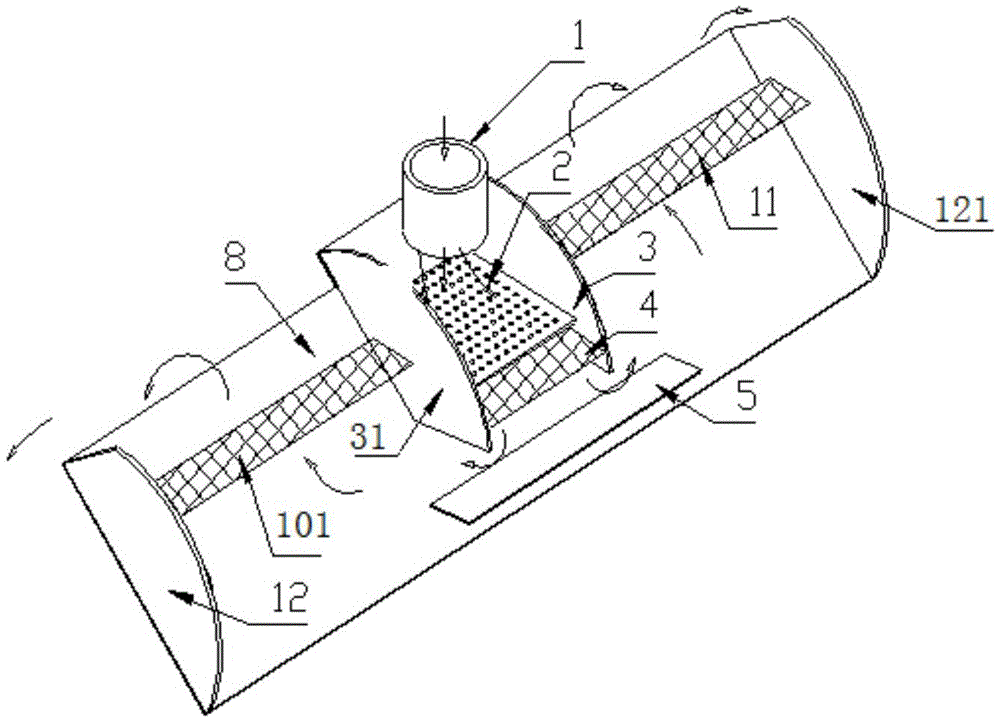

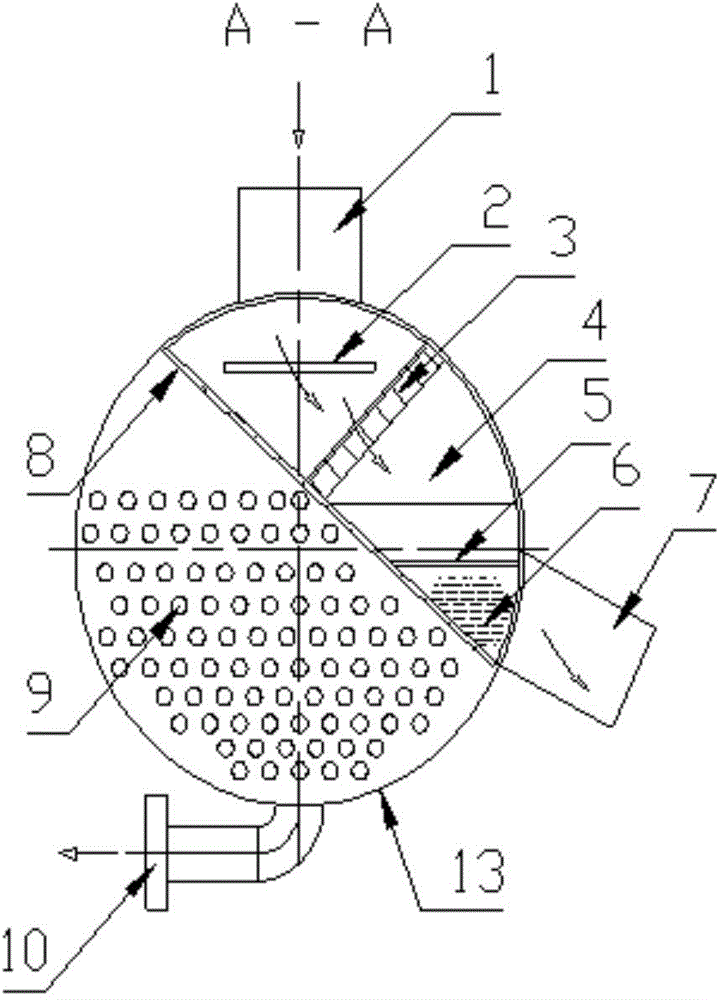

[0017] Attached below figure 1 , 2 , 3, 4 and embodiment further illustrate the present invention:

[0018] This embodiment is a built-in oil separator condenser used in a refrigeration and air-conditioning unit with a heat load of 690KW and a model of C2209. It includes an air intake pipe 1, a built-in oil group, an oil collection pipe group 7, and a condensing heat exchange pipe group. 9. Liquid outlet pipe group 10, condenser cylinder 13, and tube plate 14, first connect the air inlet pipe 1, liquid outlet pipe group 10, and oil collecting pipe 7 according to figure 1 Assemble with the condenser cylinder 13, wherein the built-in oil group is composed of the gas baffle 2, the first baffle 3, the second baffle 31, the third baffle 5, the fourth baffle 12, the fifth baffle 121, The first stainless steel filter screen group 4, the second stainless steel filter screen group 11, the third stainless steel filter screen group 101, and the convex partition 8 are composed of figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com