Energy-saving uniform temperature refrigerator

A refrigerator and freezer technology, applied in the field of energy-saving refrigerators, can solve the problems of difficulty in achieving precise temperature control, the frequency of starting and stopping should not be too high, and the temperature fluctuation of the refrigerator compartment, so as to achieve an excellent fresh-keeping environment, reduce refrigerator energy consumption, and solve temperature problems. The effect of large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

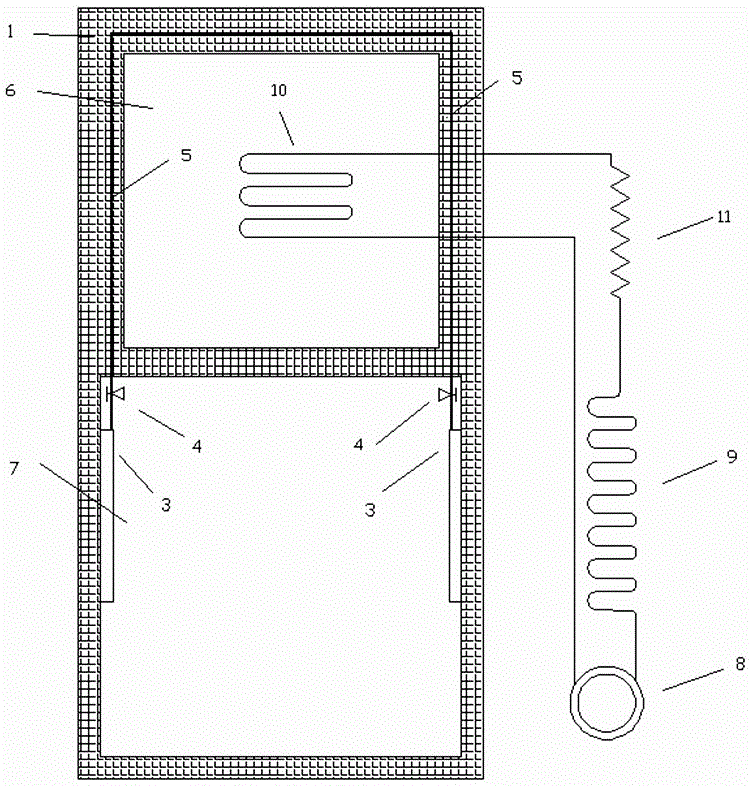

[0021] see figure 1 The energy-saving uniform temperature refrigerator includes a freezer 6, a freezer 7, a compressor 8, a condenser 9, an evaporator 10, and a capillary 11. The walls of the freezer 6 and the freezer 7 are filled with polyurethane foam. The foam material 1; the freezing chamber 6 is located in the upper part, and the refrigerating chamber 7 is located in the lower part of the freezing chamber 6. Annular heat pipe mechanisms are respectively installed in the top, back and two side walls of the freezer except the freezer door and the partition wall between the freezer and the freezer.

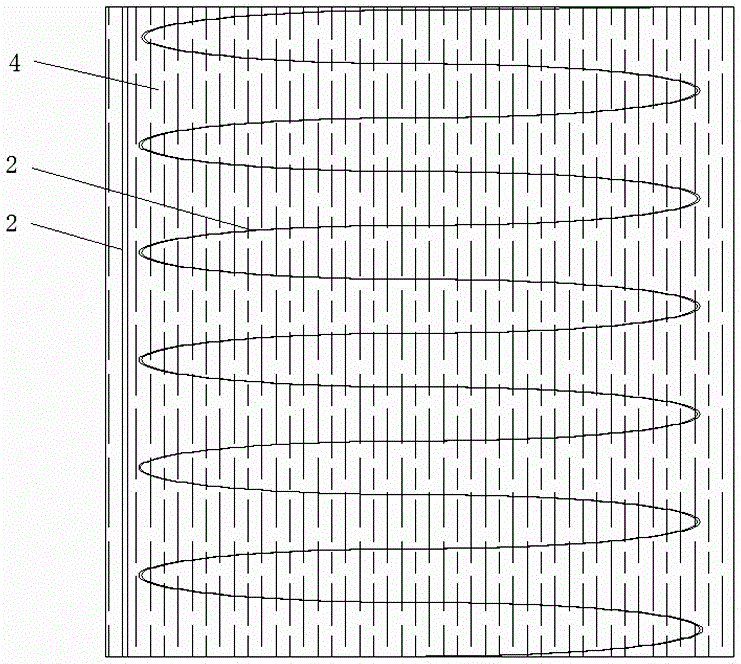

[0022] see figure 1 and figure 2 , the structure of the annular heat pipe mechanism in the top, back and two side walls of the freezing chamber 6 is as follows:

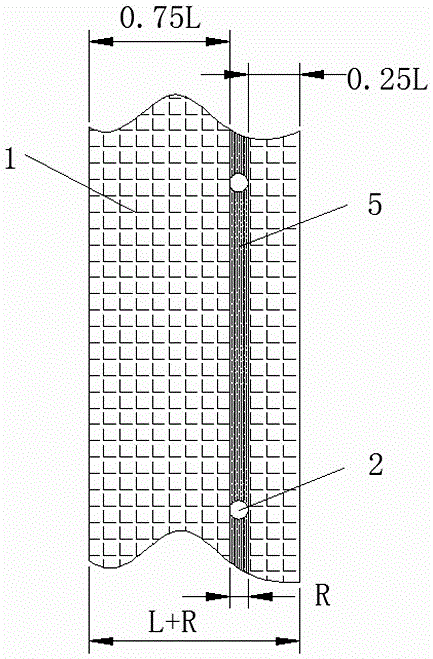

[0023] The annular heat pipe mechanism located at the back of the freezing chamber 6 is composed of a heat conducting plate 5 and an annular heat pipe. In the refrigerator compartment 7.

[0024] The annular heat...

Embodiment 2

[0028] The distance between the heat conducting plate 5 and the inner side wall of the freezing chamber 6 is one-eighth of the wall thickness of the freezing chamber 6, and the other structures are the same as in Embodiment 1.

Embodiment 3

[0030] The distance between the heat conducting plate 5 and the inner side wall of the freezing chamber 6 is one-third of the wall thickness of the freezing chamber 6, and the other structures are the same as in Embodiment 1.

[0031] The working principle of the present invention is described as follows:

[0032] see figure 1 , when the temperature of the refrigerating chamber 7 is high, the temperature control valve 4 is opened, and the working medium in the multiple annular heat pipe pipes is heated and evaporated into a gaseous state in the evaporation section 3 of the annular heat pipe, and the gas rises into the condensation section of the annular heat pipe to exchange heat with the heat conducting plate 5 Cooled into a liquid state, the condensed liquid working medium then relies on capillary force and gravity to return to the evaporation section 3 of the annular heat pipe to complete the cycle, and at the same time the working medium transfers the cold energy of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com