Energy-saving dryer

A dryer and organic technology, applied in the field of dryers, can solve the problems of large volume, long drying time and high cost, and achieve the effects of simple overall structure, short drying time and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation case of the present invention is described below in conjunction with accompanying drawing:

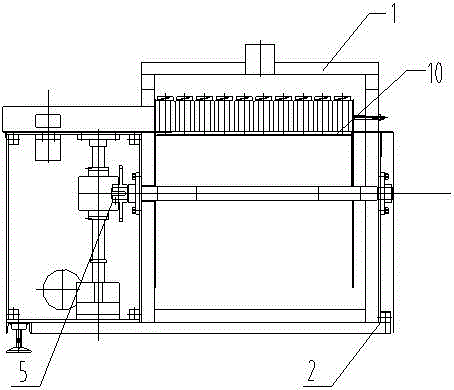

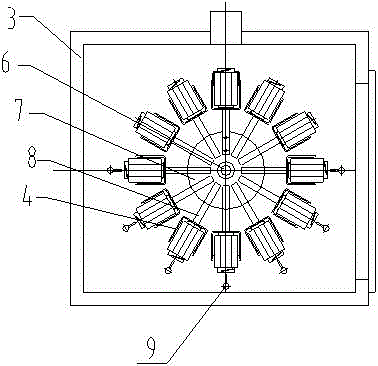

[0019] Such as figure 1 and figure 2 As shown, an energy-saving dryer includes a box body 1, a frame 2 is arranged in the box body 1, and a transmission mechanism 5 is arranged on the frame 2. Specifically, the transmission mechanism 5 passes through a transmission belt 10 in turn After passing through the preheating zone and the heating zone, it is connected with the circularly rotating drum 3, and the preheating zone and the heating zone are provided with heating pipes and mesh belt heating pipes (the prior art, not shown in the figure). And there are 23 heating tubes with a rated power of 2KW; there are 12 mesh belt heating tubes, and the power of the 12 mesh belt heating tubes is 70KW in total. The cleaned bottles are preheated in the preheating zone on the conveyor belt in turn. And the heating zone enters into the drum 3 after being heated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com