Multifunctional optical material testing device

A technology of optical materials and testing devices, which is applied in the direction of measuring devices, material analysis through optical means, and analysis of materials, etc., can solve the problems of inconvenient use, single parameter, high cost, etc., and achieve user convenience, cost reduction, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

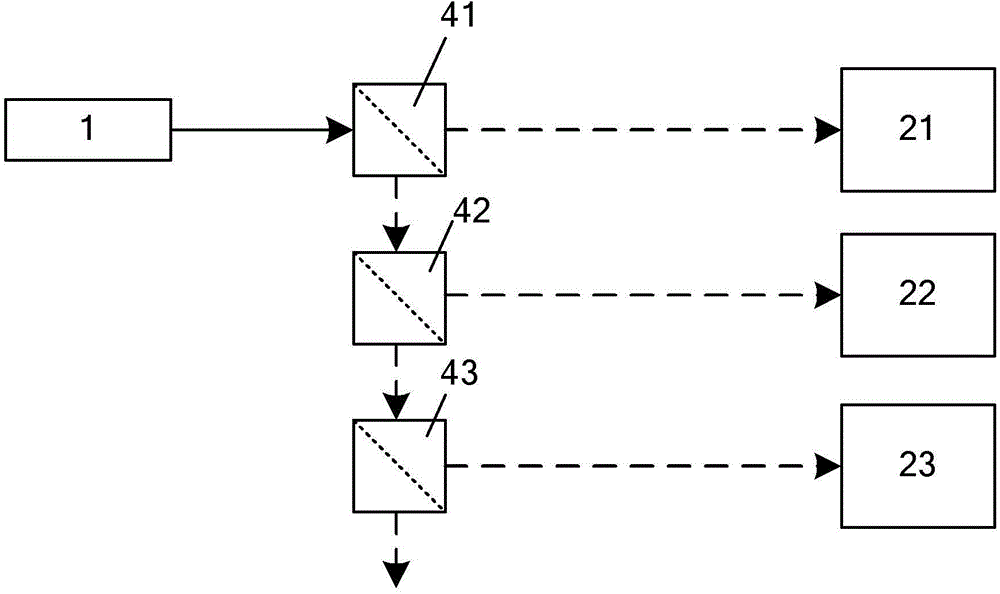

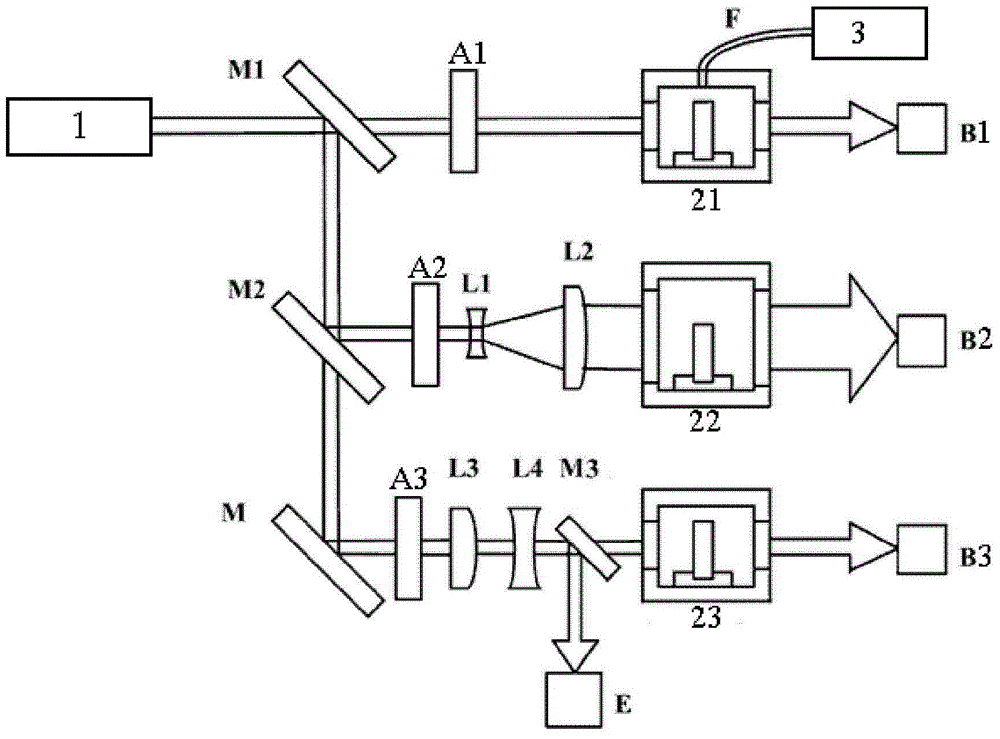

[0021] figure 1 It is a schematic structural diagram of the multifunctional optical material testing device of the present invention. like figure 1 As shown, the test device includes a laser 1 , multiple mirror mounting mechanisms 41 , 42 , 43 , and multiple sample chambers 21 , 22 , 23 . Each reflector mounting mechanism corresponds to each sample chamber one by one. The sample chamber is used to load the optical material to be tested, and receives the laser from the laser 1 or the reflector installation mechanism to irradiate the optical material. Note that in the figure 1 Only three mirror mounting mechanisms and three sample chambers are shown, but the invention is not limited to a specific number.

[0022] The reflector installation mechanisms 41, 42, 43 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com