MPO/MTP cluster prefabricated optical cable component

A technology of prefabricated optical cables and components, applied in the field of optical transmission, can solve the problems of large optical transmission loss, automatic loosening, unreliability, etc., and achieve the effects of ensuring optical fiber transmission performance, preventing mis-insertion operations, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

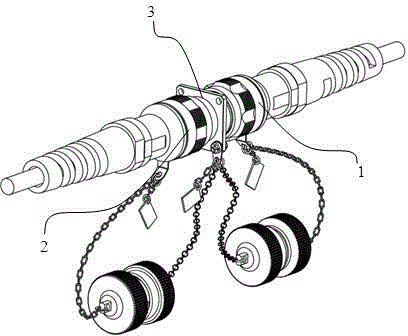

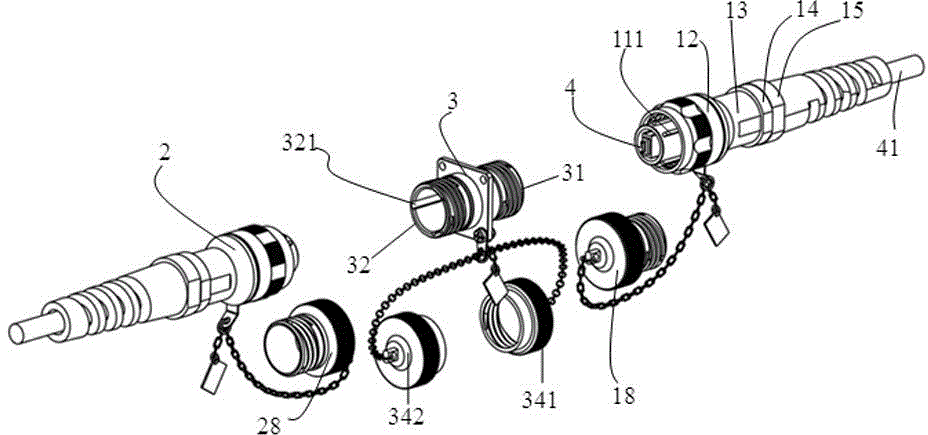

[0051] An MPO / MTP bundled prefabricated optical cable assembly, which includes: a first optical fiber connector 4 whose tail is preset with a first optical cable 41, and a second optical fiber connector whose tail is preset with a second optical cable, the first optical fiber connector 4 The head of the second optical fiber connector is aligned and coupled with the head of the second optical fiber connector to form an optical transmission link. In this embodiment, the first optical fiber connector 4 is an MPO / MTP male head, and the second optical fiber connection The adapter is an MPO / MTP female head, and both the MPO / MTP male head and the female head end contain a T-shaped adapter.

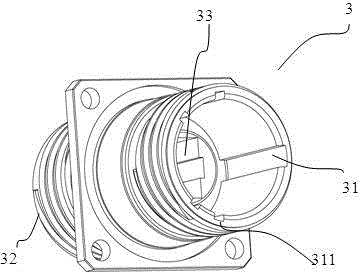

[0052] Such as figure 1 , 2, 4, the prefabricated optical cable assembly also includes: an adapter assembly 3 with openings 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com