Organic electroluminescent device and preparation method thereof

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex process, increase the number of evaporation alignment times, unfavorable mass production, etc., and achieve simplification The effect of technology, improvement of yield rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

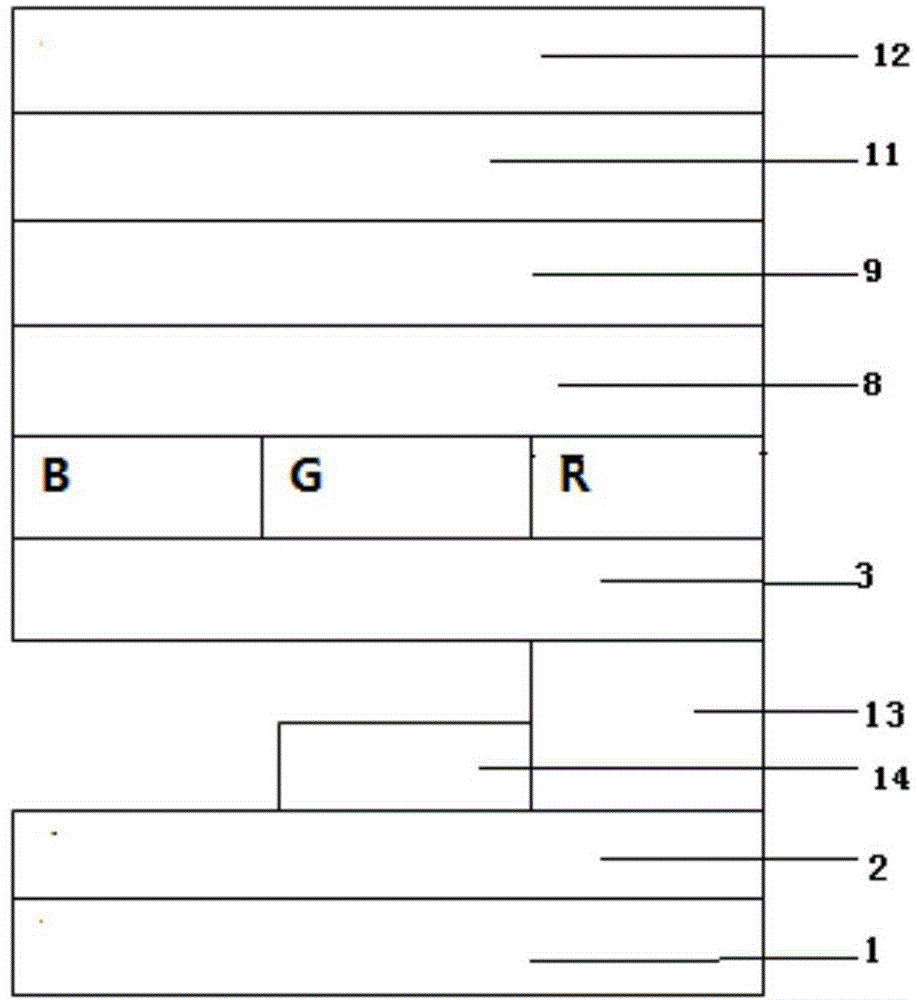

[0041] Such as image 3 As shown, an organic electroluminescent device of the present invention includes a substrate (not shown in the figure), and a first electrode layer 1, several light-emitting unit layers and a second electrode layer sequentially formed on the substrate, Each of the light-emitting unit layers includes a first organic functional layer, a light-emitting material layer, and a second organic functional layer arranged on the first electrode layer 1, and the light-emitting material layer includes a blue light-emitting layer 4 and a green light-emitting layer 5 and a red light-emitting layer 6, the blue light-emitting layer 4 covers the first organic functional layer, the green light-emitting layer 5 is stacked on the blue light-emitting layer 4 and covers part of the blue light-emitting layer 4, the red light-emitting layer A barrier layer 7 is arranged between the light emitting layer 6 and the green light emitting layer 5. The barrier layer 7 described in thi...

Embodiment 2

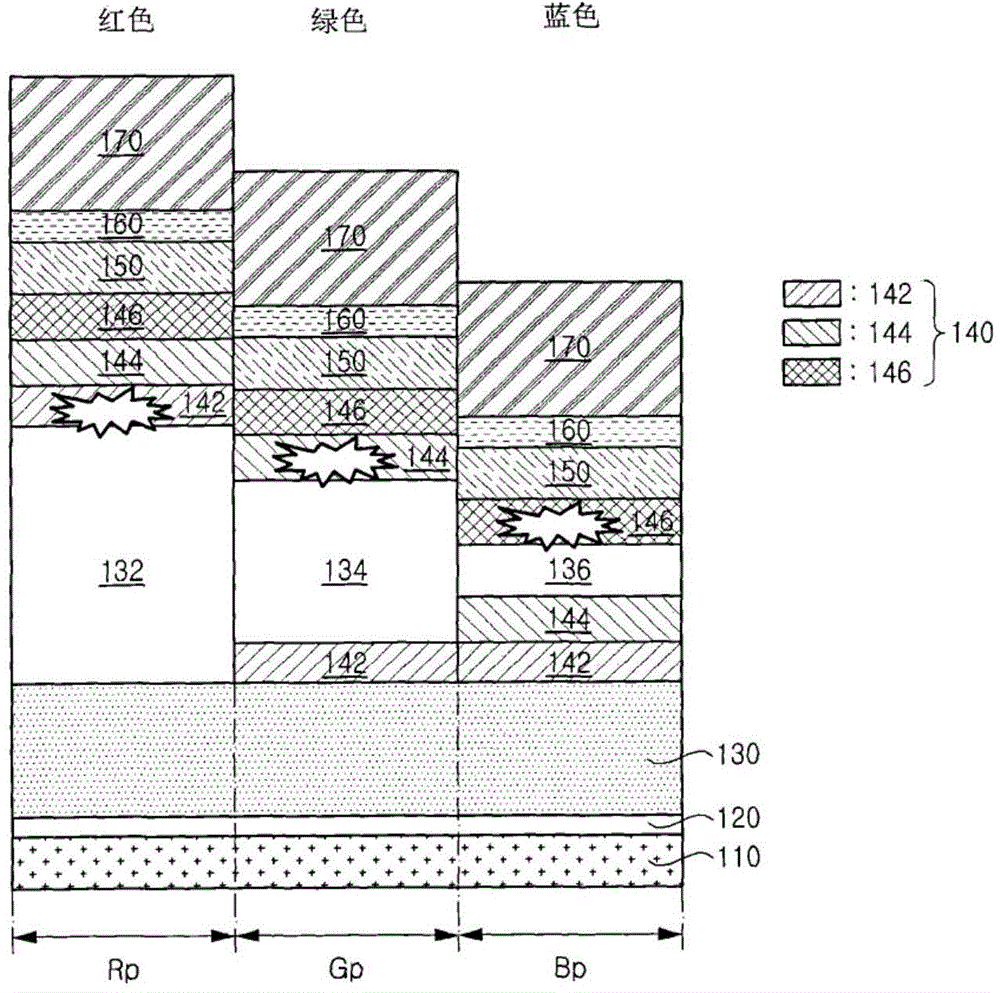

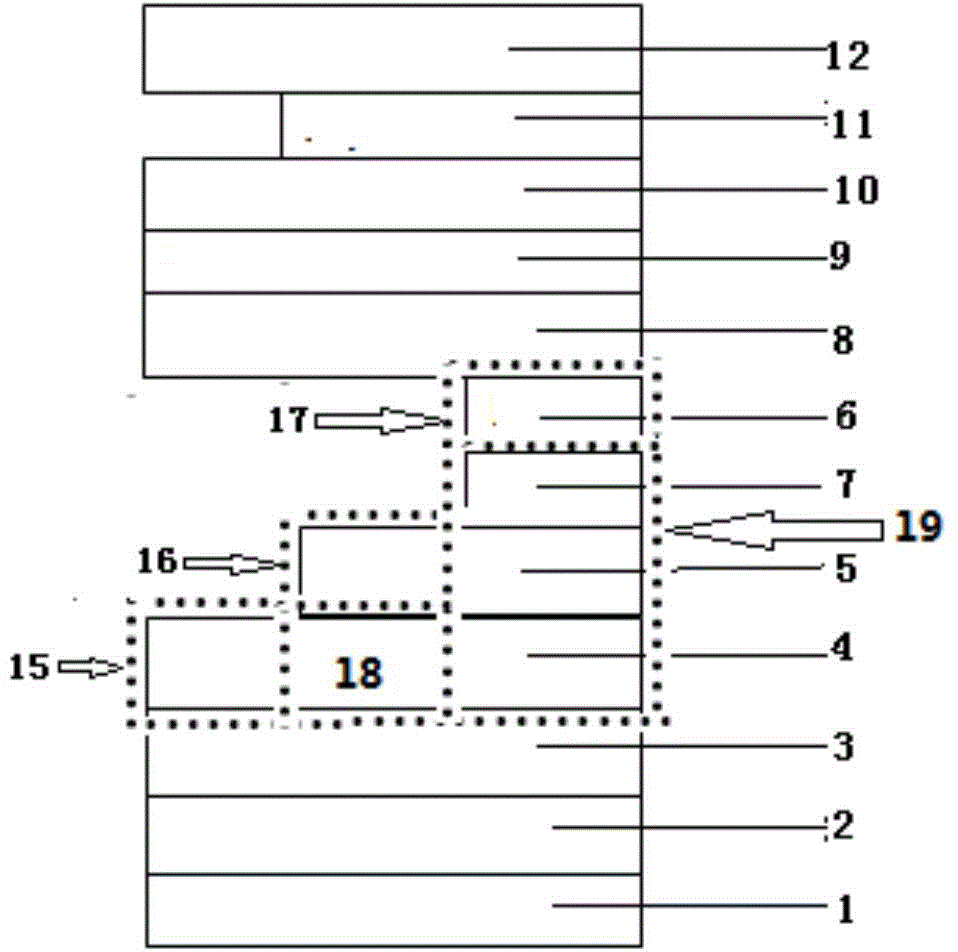

[0057] Figure 4 A kind of organic electroluminescent device of the present invention shown, its structure is the same as embodiment 1, and wherein luminescent material layer comprises blue light emitting layer 4, green light emitting layer 5 and red light emitting layer 6, and red light emitting layer 6 is arranged on On the first organic functional layer, the barrier layer 7 above the red light emitting layer 6 is a hole barrier layer, the green light emitting material layer 5 is above the hole barrier layer, and the blue light emitting material layer 4 is above the green light emitting material layer 5, The blue light emitting layer 4 is covered by the second organic functional layer. Compared with the embodiment, the upper and lower positions of the red light emitting layer 6, the hole blocking layer, the green light emitting layer 5 and the blue light emitting layer 4 are reversed, and the stacking method remains unchanged. The red optical compensation layer 19 is still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com