Conductive contact piece and electrical connection contact strip with same

A technology of conductive contact piece and contact piece, applied in the direction of contact parts, etc., can solve the problems of poor contact consistency, large contact resistance, affecting conductivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

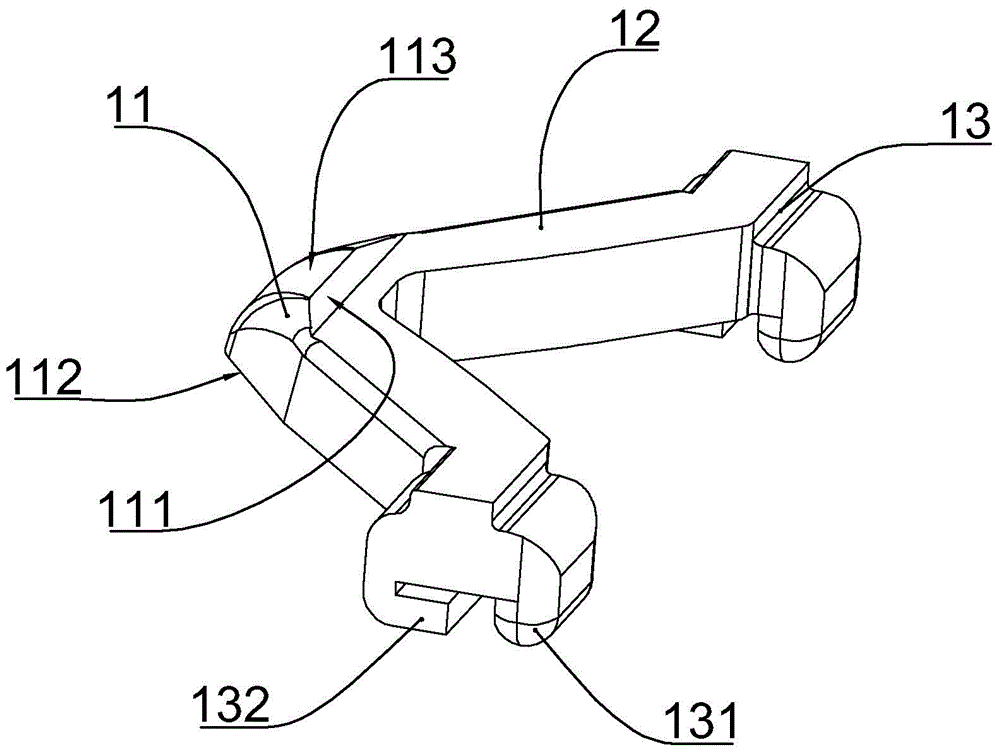

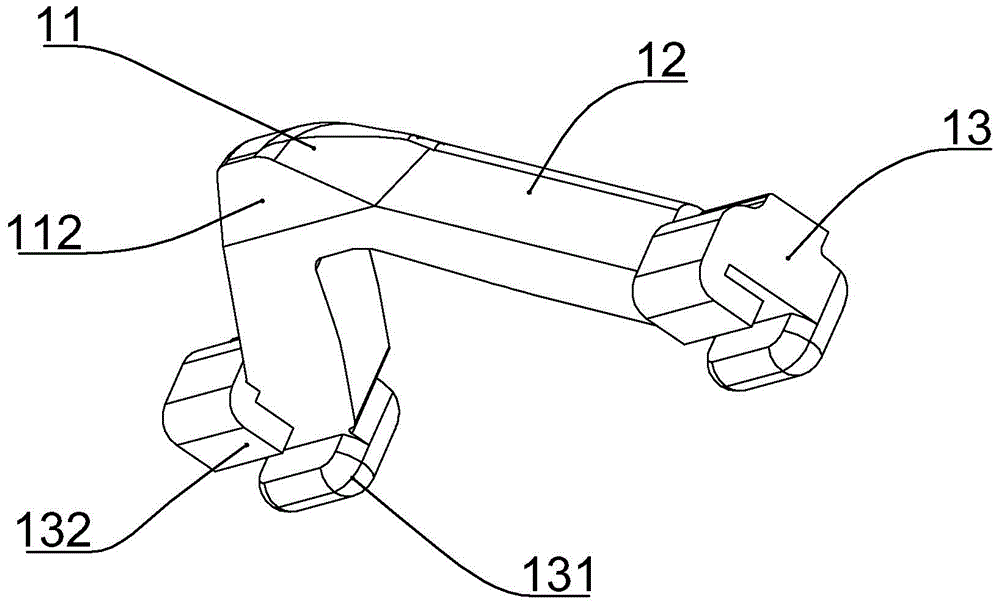

[0024] according to Figure 1 to Figure 2 As shown, the conductive contact piece of this embodiment includes a top conductive end 11, two symmetrically arranged conductive arms 12 integrally connected to the top conductive end, and a bottom conductive end 13 integrally connected to the end of the conductive arm. The upper end surface of the above-mentioned top conductive terminal is a top conductive contact 113 whose contact area is in a line shape, and the line-shaped contact area is parallel to the connecting line of the two bottom conductive terminals.

[0025] The top conductive contact overall has an arc-shaped surface, and the line-shaped contact area is located on the arc-shaped surface. In this way, when the movable contact is in contact with the contact area of the top conductive contact, the contact area can always be kept in a line shape.

[0026] A riveting edge 132 and a bottom conductive contact 131 opposite to the riveting edge are integrally connected below ...

Embodiment 2

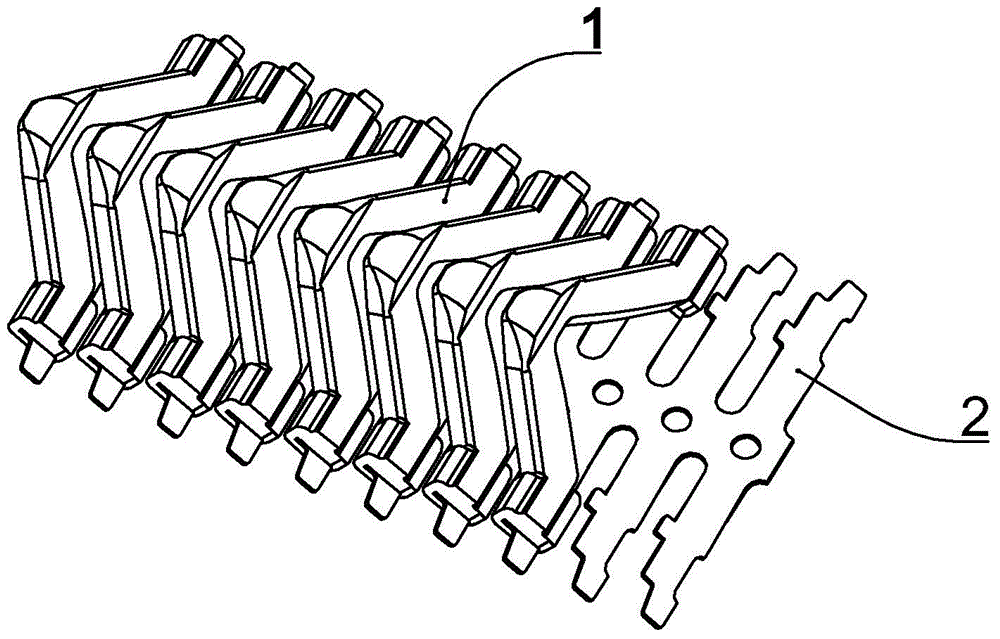

[0031] to combine Figure 1 to Figure 6 As shown, the electrical connection contact strip of this embodiment includes one or more conductive contact strips 1 described in Embodiment 1, and also includes an elastic steel strip 2; both sides of the elastic steel strip are connected with equal intervals. The torsion arm 25 of integral structure, the elastic steel band is positioned at the position between every two relative torsion arms and is provided with assembly location hole 20, and the torsion angle of torsion arm is 15-20 degree, and the riveting edge 132 of described conductive contact piece and The outer end of the torsion arm is riveted and fixed.

[0032] The side of the torsion arm 25 close to the outer end is formed with a bottom conductive contact limiting opening 24 that is positioned in cooperation with the bottom conductive contact 131 on the conductive contact piece. The bottom conductive contact 131 cooperates with the bottom conductive contact limit opening 2...

Embodiment 3

[0037] The planar electrical connector of this embodiment has adopted the contact strip described in Embodiment 2, as Figure 7 As shown, the contact strip is installed on the static contact 4, and the movable contact 3 and the top conductive contact 113 are in close contact with each other due to the elasticity of the elastic steel strip. Similarly, the static contact 4 and the bottom conductive contact Point 131 close contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com