Thick steel plate with excellent toughness in welded heat-affected zone

A technology for welding heat-affected and thick steel plates, which is applied in the field of thick steel plates, can solve problems such as increasing the burden on operators, and achieve the effects of excellent productivity and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Below, the present invention is described in more detail by enumerating the examples, but the present invention is certainly not limited by the following examples, and within the scope that can meet the purpose of the present invention, it can also be appropriately modified and implemented, and these are all included in the technology of the present invention. within range.

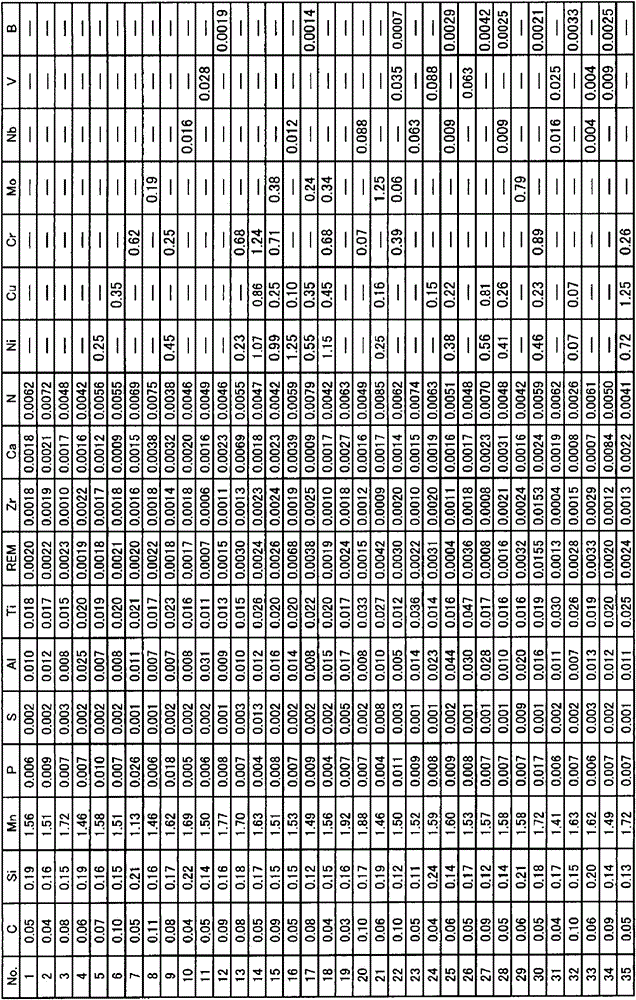

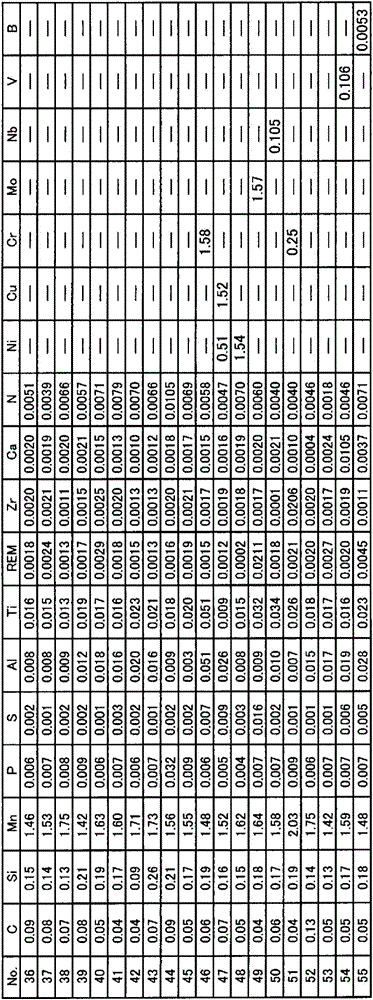

[0100] In the embodiment of the present invention, first, after melting the steels with the compositions shown in Table 1 and Table 2 in a vacuum furnace (VIF: 150 kg), cast slabs (cross-sectional shape: 150 mm × 250 mm) were cast using the molten steel, Further, the cast slab was hot-rolled to obtain a hot-rolled sheet having a thickness of 80 mm. In addition, hot rolling conditions were heating before rolling: 1100°C x 3 hours, finish rolling temperature: 780°C or higher, average cooling rate to 450°C: 6°C / s, and cooling stop temperature: 450°C.

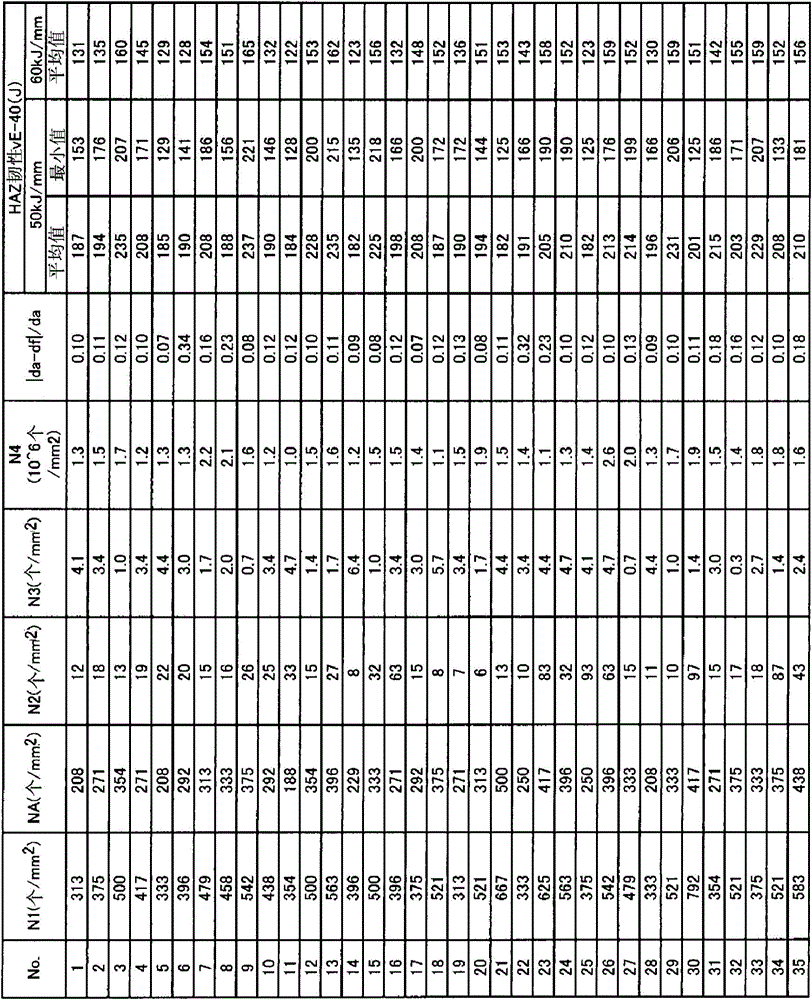

[0101] Tables 3 and 4 show various conditions co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com