Measuring element and method for differentiating different liquids

A technology of measuring components and liquids, which is applied in the direction of engine components, electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve the problems of DENOX system quality reduction or function deterioration, and achieve the goal of improving the judgment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention is explained in more detail below on the basis of the exemplary embodiments shown in the drawings, as well as according to further advantageous configurations. Identical components or components with the same function are identified with the same reference symbols in the figures.

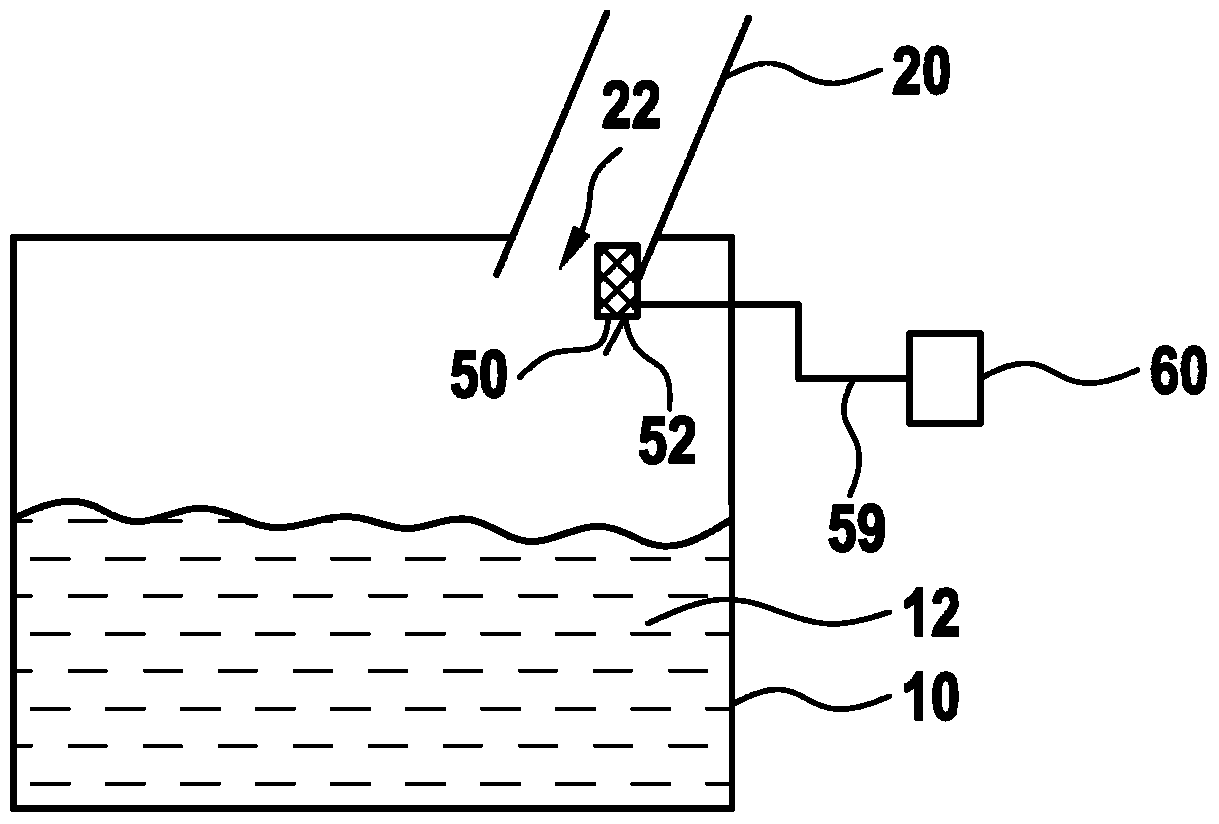

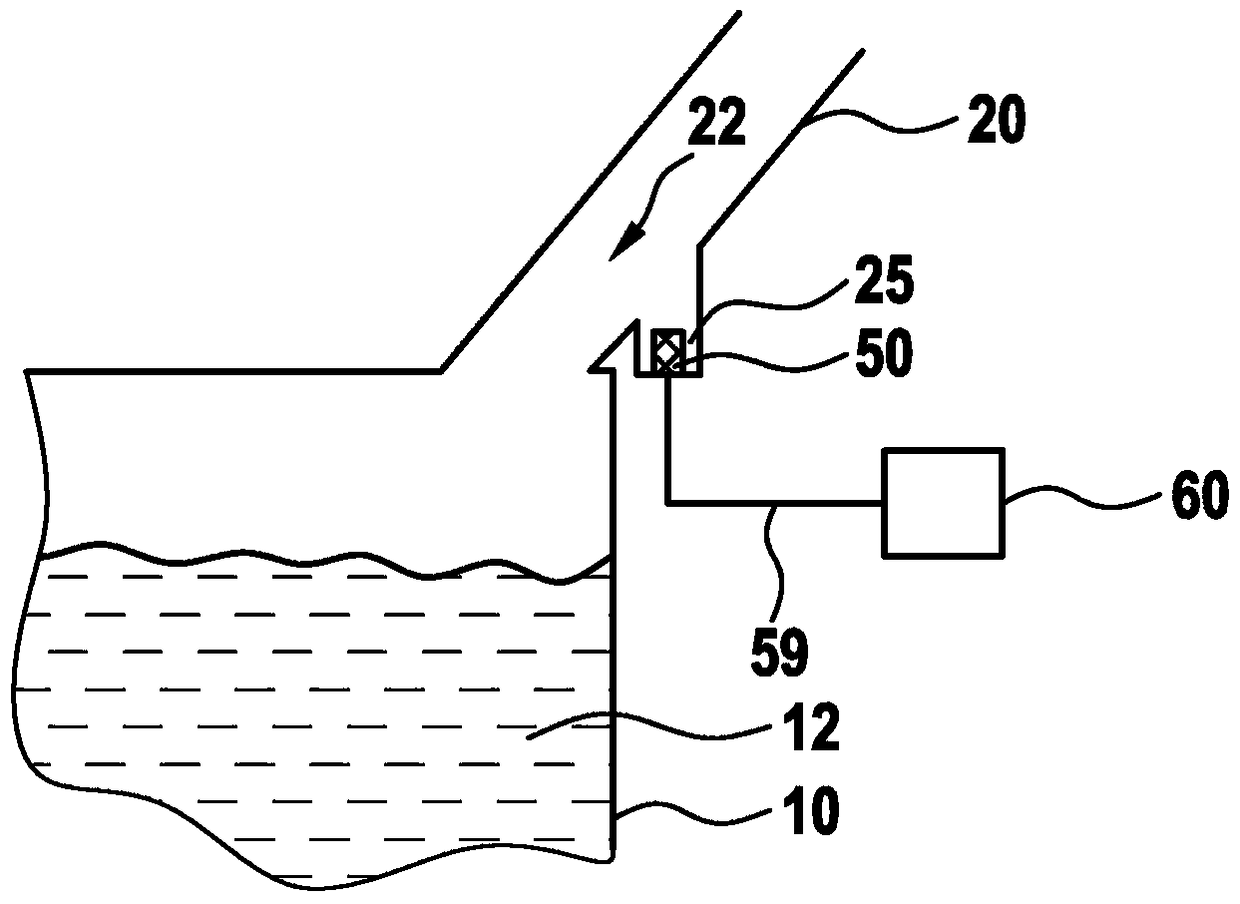

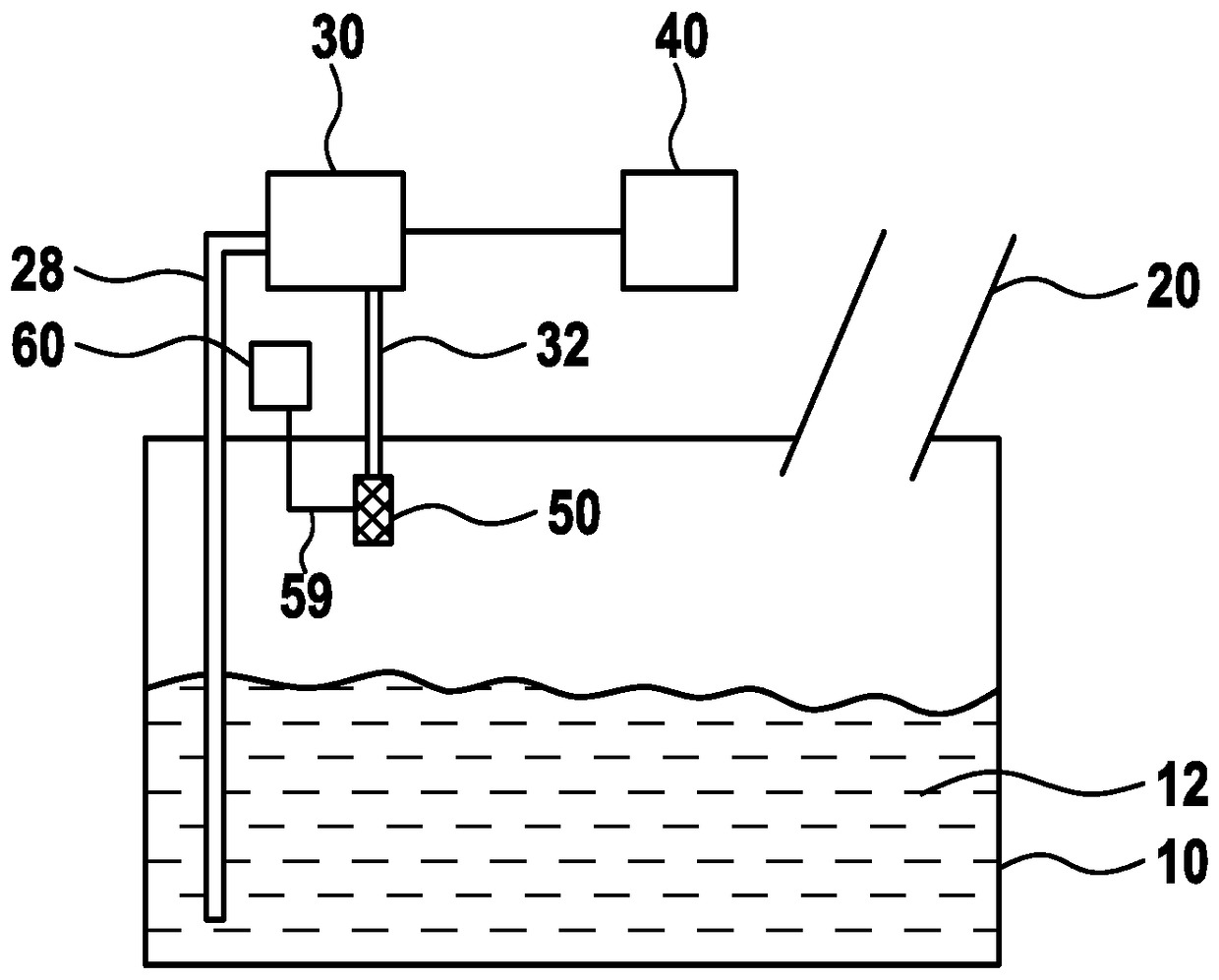

[0020] exist figure 1 A storage container 10 for storing a liquid 12 , for example an aqueous urea solution, is shown in , with a filling connection 20 , wherein the filling connection 20 opens into an inlet region 22 . A measuring element 50 for detecting the material properties of the liquid is arranged in the inlet region 22 , wherein the measuring element 50 is connected to a measuring device 60 via a signal line 59 .

[0021] Depending on certain properties of the liquid 12 or derivatives of the liquid 12, for example aqueous urea as liquid 12 or solid urea or urea crystals as a derivative of liquid 12, it is relatively simple to determine the mass of the liquid with suffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com