Piezoelectric body, piezoelectric device, and liquid discharge apparatus

A piezoelectric body, liquid technology, applied in the field of piezoelectric body, can solve the problem of unable to maintain operation efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

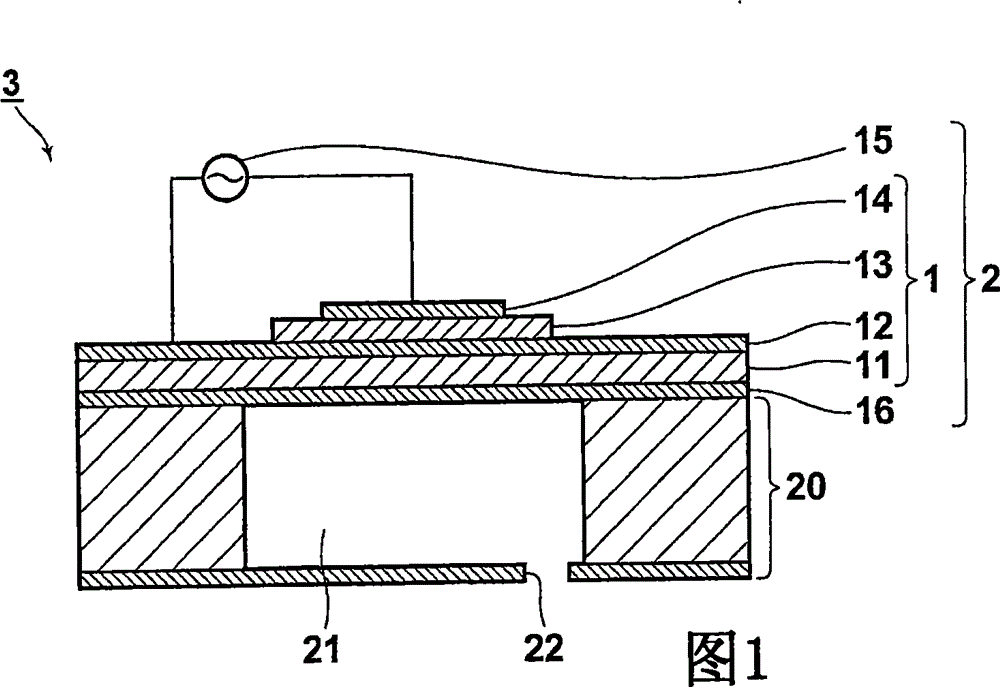

[0158] The bottom plate is made of Si sheet. In addition, using sputtering technology, an Ir bottom electrode with a thickness of 150 nm, a Nb-doped PZT piezoelectric film with a thickness of 5.0 μm, and a Pt top electrode with a thickness of 150 nm were sequentially formed on the surface of the base plate. In this way, the piezoelectric device of the present invention can be obtained. Each of the bottom electrode, the piezoelectric thin film, and the top electrode is formed over the entire bottom plate area. The composition of the piezoelectric thin film was set so that the Zr / (Zr+Ti) molar ratio was equal to 0.52, and so that the Nb doping concentration at the B site was equal to 13 mol%.

[0159] For the piezoelectric thin film described above, simultaneous X-ray diffraction (XRD) measurement was performed. Figure 5 The XRD patterns in the initial state (that is, the state where no electric field is applied), the state when an electric field is applied at 50 kV / cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com