Method for carrying out auxiliary cutting through atomized cold plasmas

A technology of cold plasma and plasma, which is applied in the field of plasma jet assisted cutting, and can solve problems such as difficult to achieve ideal results and burns on the workpiece surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

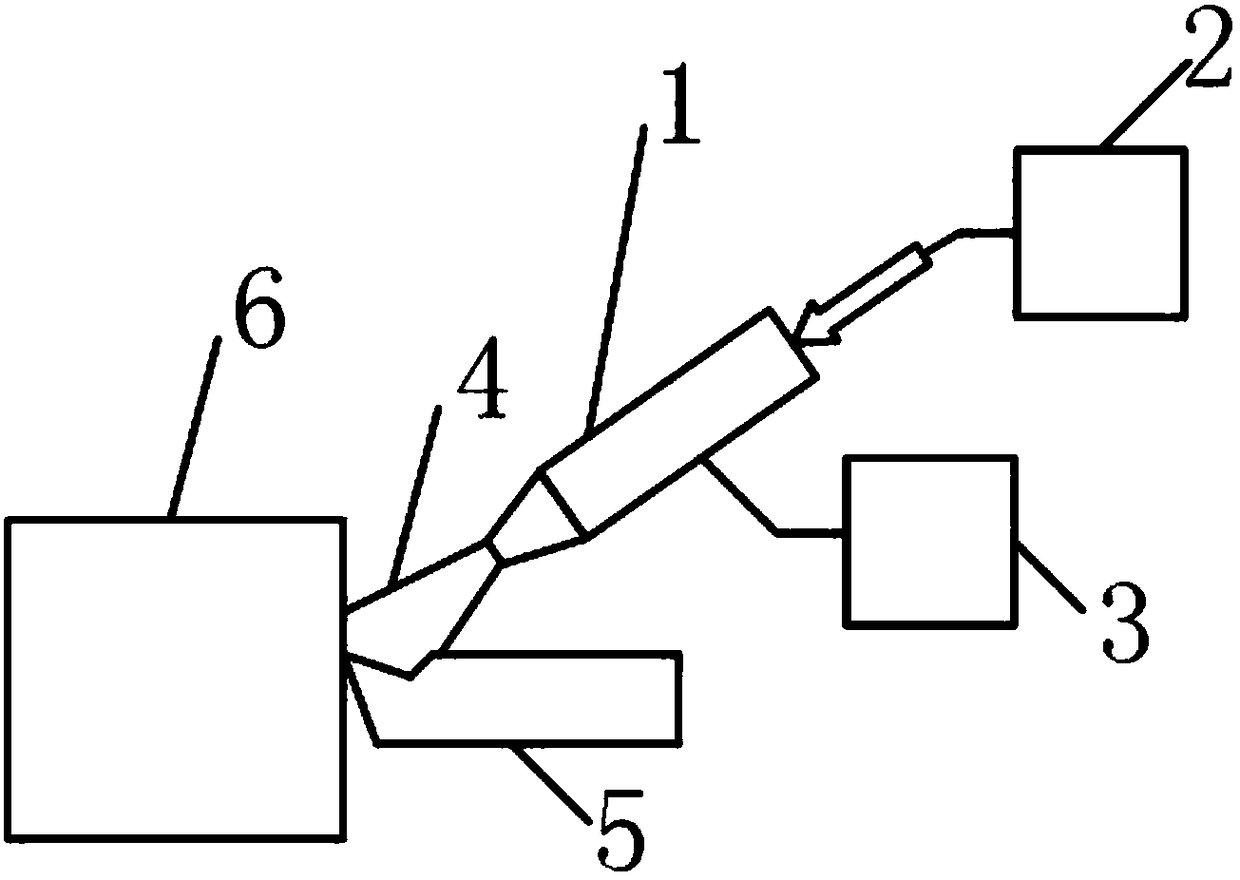

Method used

Image

Examples

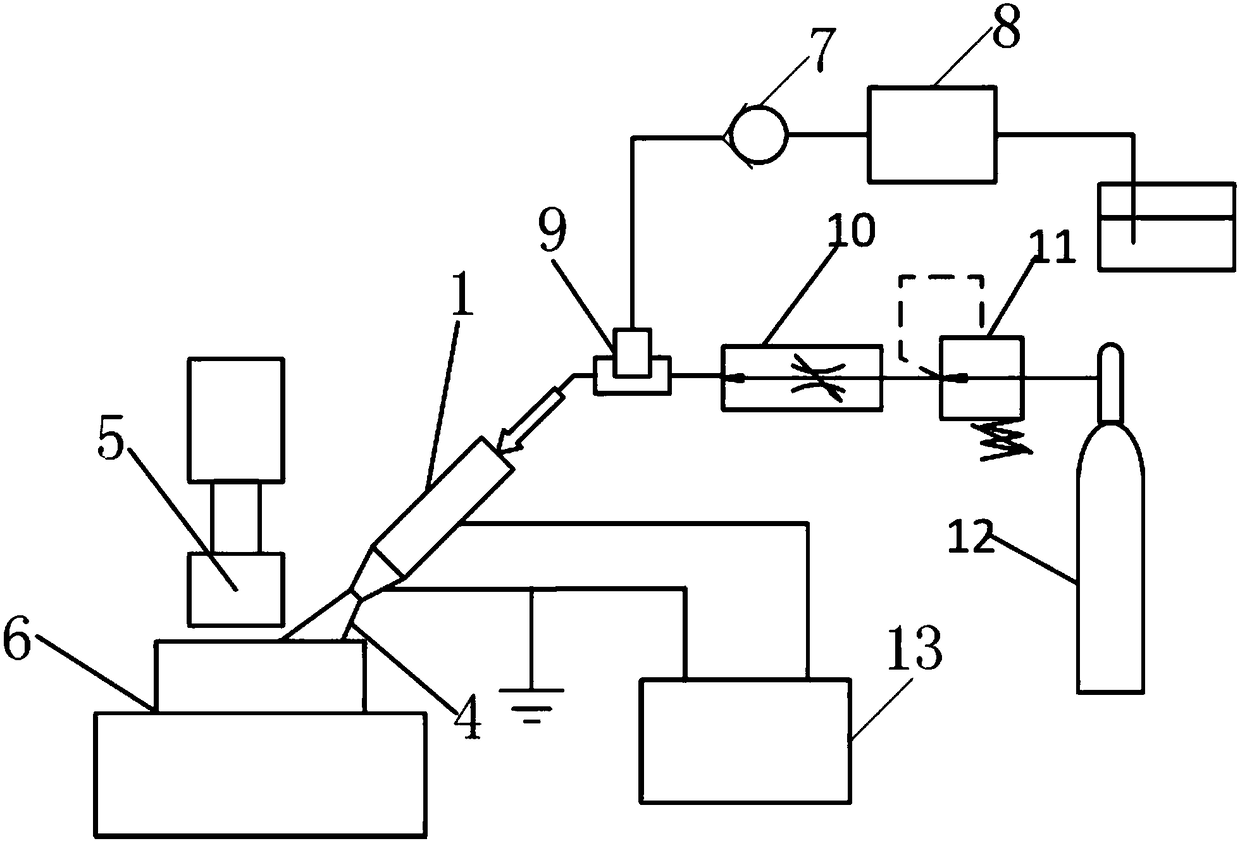

Embodiment 1

[0032] Example 1 can realize atmospheric pressure atomized cold plasma assisted micro-milling of nickel-based superalloy.

[0033] The bare electrode cold plasma jet generator 1 uses the discharge form of the bare electrode. The atmospheric pressure cool plasma jet generated by this electrode will not cause breakdown discharge between the processed material. The positive pole of 13, that is, the high-voltage output end is connected to the high-voltage tungsten needle electrode, and the low-voltage output end is connected to the low-voltage copper electrode at the nozzle and grounded.

[0034] The working gas source 12 adopts high-purity nitrogen with a purity of 99.999%.

[0035] After the workpiece 6 is fixed on the working platform, the bare electrode cold plasma jet generator 1 is fixed on the Z-axis of the milling cutter, so that the distance between the jet and the workpiece contact area of the cutter is 10mm.

[0036] Open the pressure reducing valve 11, adjust the fl...

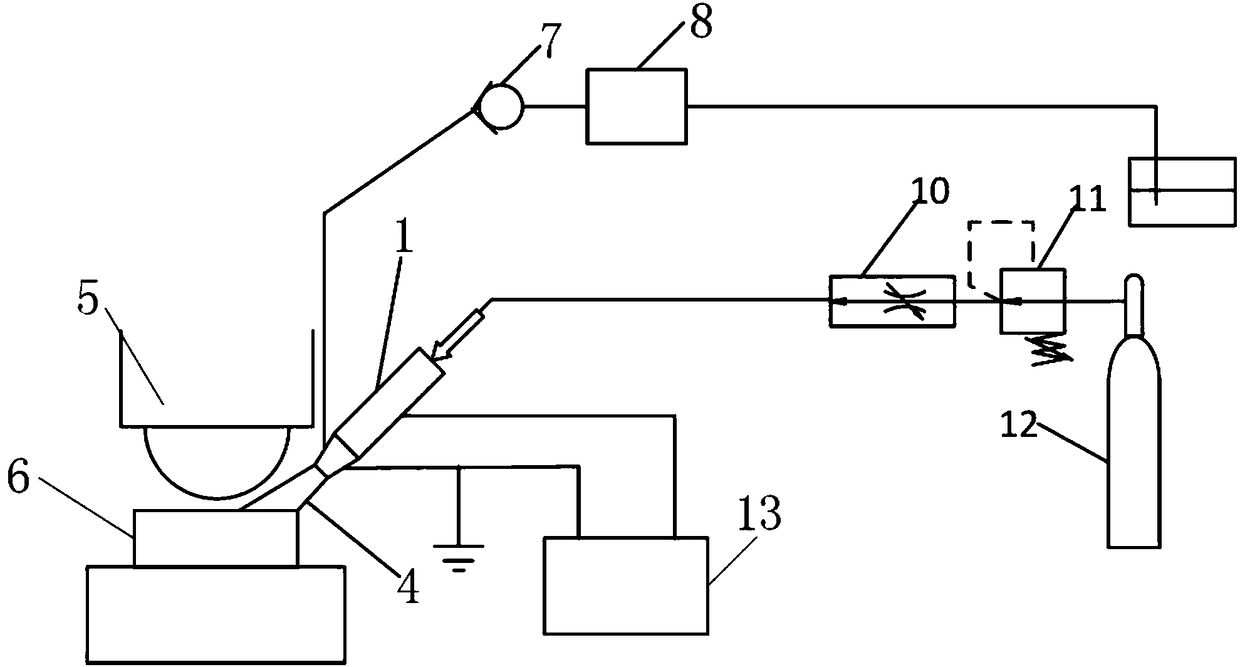

Embodiment 2

[0038] Example 2 can realize atmospheric pressure atomized cold plasma assisted grinding.

[0039] The bare electrode cold plasma jet generator 1 uses the discharge form of the bare electrode. The atmospheric pressure cool plasma jet generated by this electrode will not cause breakdown discharge between the processed material. The positive pole of 13, that is, the high-voltage output end is connected to the high-voltage tungsten needle electrode, and the low-voltage output end is connected to the low-voltage copper electrode at the nozzle and grounded.

[0040] The working gas source 12 adopts high-purity nitrogen with a purity of 99.999%.

[0041] After the workpiece 6 is fixed on the working platform, the bare electrode cold plasma jet generator 1 is fixed on the grinding wheel feed shaft, so that the distance between the jet and the tool workpiece contact area is 10 mm.

[0042]Open the pressure reducing valve 11, adjust the flow meter 10 to make the flow rate reach 10L / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com