Bearing cover, in particular an ABS sensor cap

A bearing cap and bearing technology, applied in the direction of bearings, bearing assembly, bearing components, etc., can solve the problems of lubricant entry and pressure fluctuation, and achieve the effect of ensuring orientation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

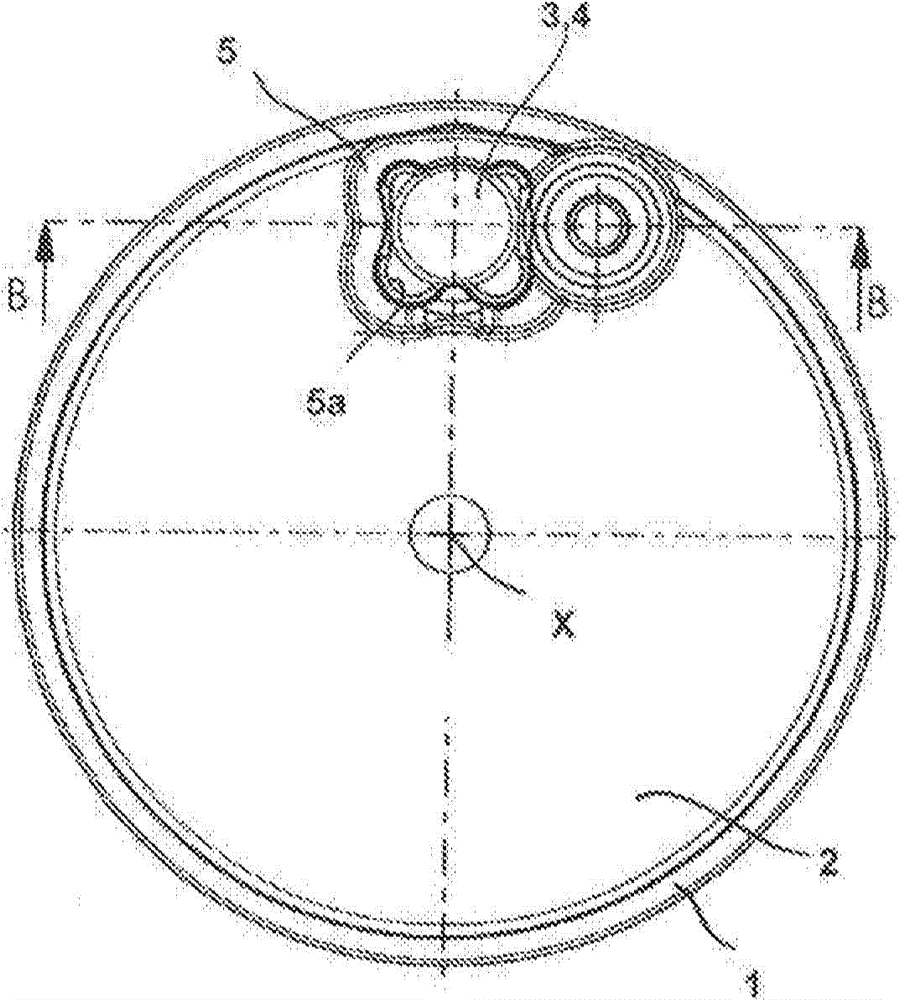

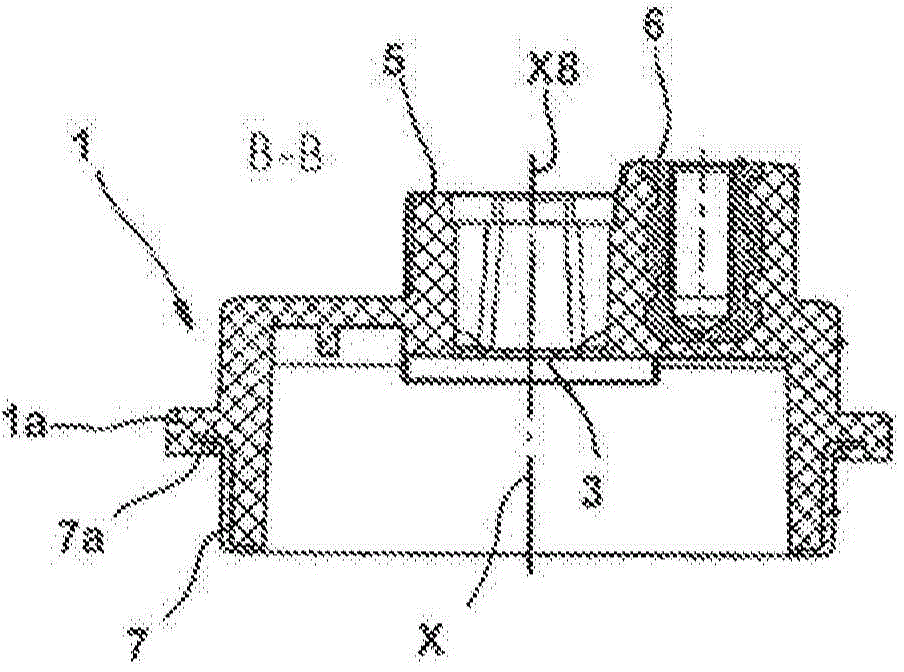

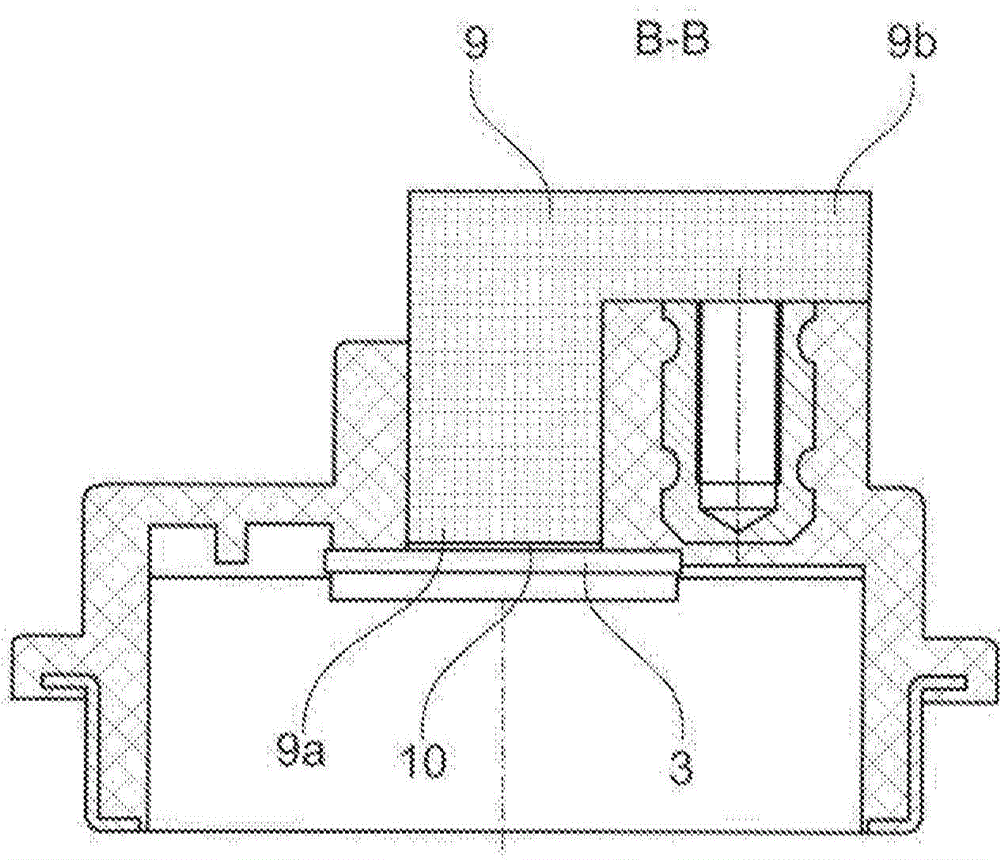

[0032] figure 1 A bearing cap according to the invention is shown in . The bearing cap is used to isolate the bearing inner area from the surrounding environment. The bearing cover comprises an annular edge section 1 spaced apart from the bearing axis X, here in particular concentric with the bearing axis X, which can be seated sealingly in a connection region of the bearing bracket not shown in detail here superior. Furthermore, the bearing cap comprises a cap section 2 which extends in the region surrounded by the annular edge section 1 and is connected to the annular edge section 1 .

[0033] The bearing cover is equipped with a membrane element 3 embodied as a gas-permeable membrane, which enables a pressure equalization between the inner area of the bearing and the surrounding environment. The membrane element is arranged on the opening section 4 . In the cover section 2 , the opening section 4 is formed at a point radially offset from the bearing axis X in the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com