Electron gun abnormality detector and electron gun abnormality detection method

An anomaly detection, electron gun technology, applied to electrode devices and related components, the size/direction of the magnetic field, and the use of magneto-optical equipment for magnetic field measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

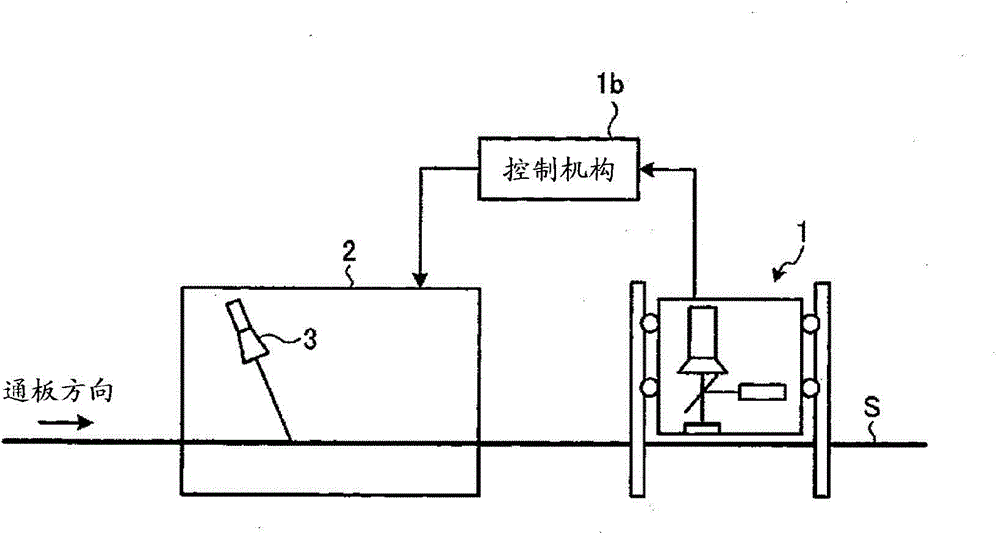

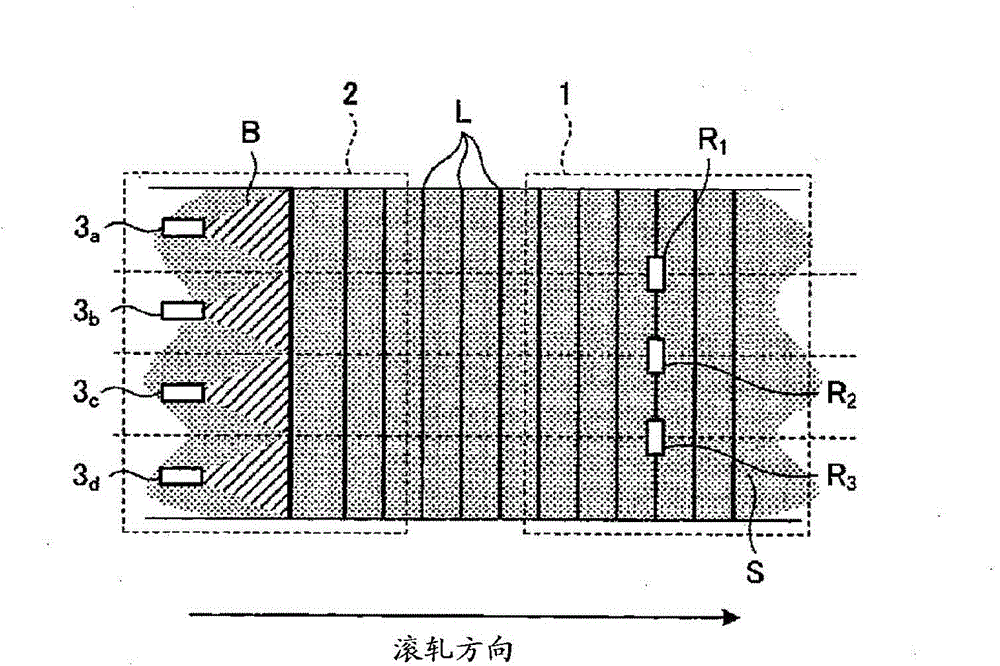

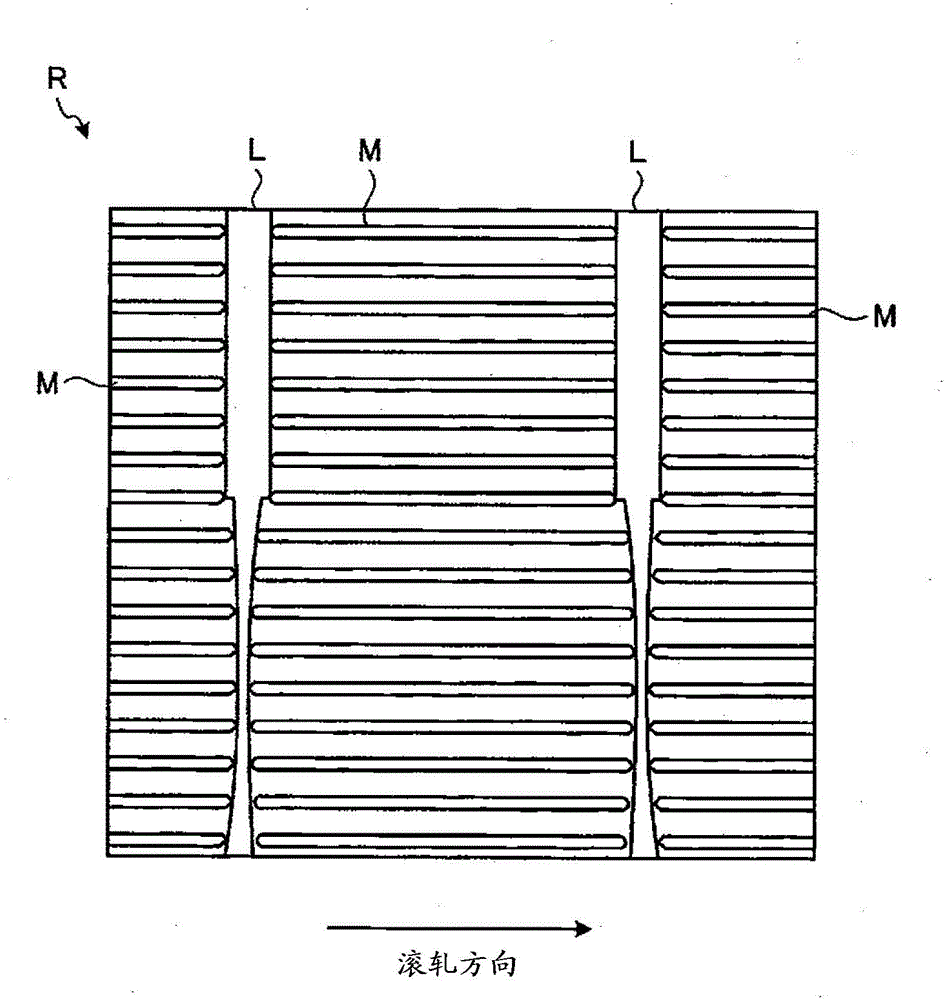

[0062] Next, an operation example of a production line in which abnormality detection processing of the electron gun 3 of the magnetic domain refining device 2 is performed by the electron gun abnormality detection method according to the embodiment of the present invention will be described. Figure 10 as well as Figure 11 It is a graph of the minimum value of the width of the magnetic domain discontinuity detected by the electron gun abnormality detection method according to the embodiment of the present invention.

[0063] Figure 10 Indicates the inspection results of a production line for two days, Figure 11 is from Figure 10 The two-day inspection results of the production line 3 months after the inspection started. The inspection is performed at the time of stop when replacing the coil of the steel sheet S in the production line. in addition, Figure 10 as well as Figure 11 Example combination of diagrams figure 2 Assignment of reference symbols in the inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com