Two-ridge-four-column semi-feeding type wheel peanut combine harvester

A combined harvester and semi-feeding technology, which is applied to digging harvesters, harvesters, agricultural machinery and tools, etc., can solve the problems of inflexible walking parts and incomplete fruit picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

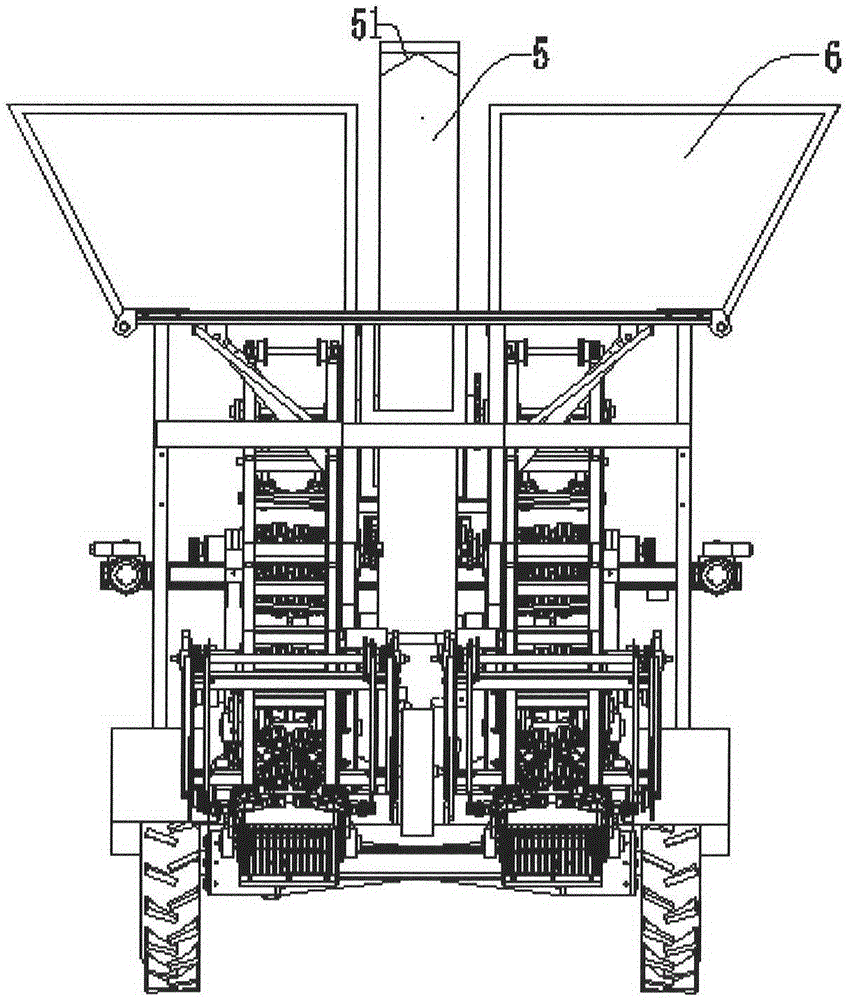

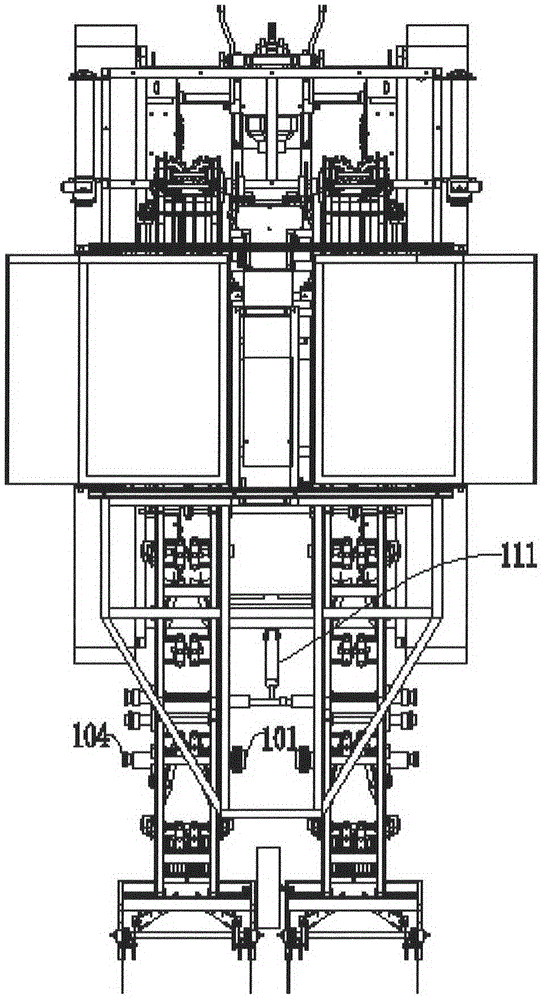

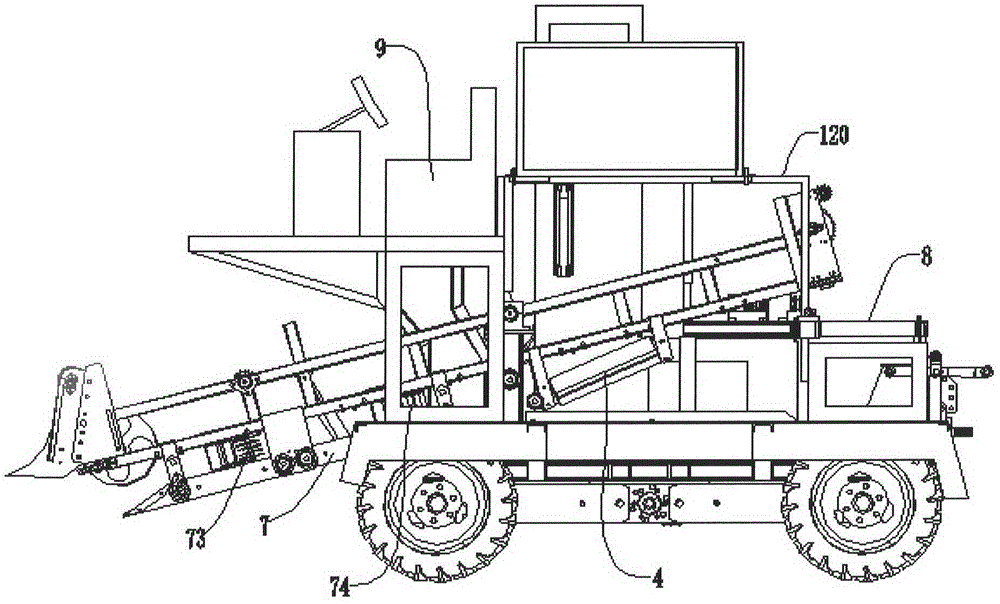

[0019] like Figure 1-5 As shown, the two ridges, four rows and a half feeding type wheeled peanut combine harvester of the present invention includes a power source (not shown in the figure), a control part (not shown in the figure), a transmission connection part, a frame 120, a walking Part 1, digging device (not shown in the figure), grain holding device 2, clamping and conveying part 3, fruit picking device 4, cleaning device (not shown in the figure), lifter 5 and fruit bin 6, also includes a recovery The device 7 is used to carry out secondary collection of the peanuts remaining in the clamping and conveying part 3 and the ground; and the conveyor belt 8 is used to transport the peanut seedlings transported by the clamping and conveying part 3 to the peanut seedling collection place through the transmission belt 8, The recovering device 7 is arranged at the bottom of the clamping and conveying part 3, and the conveyor belt 8 is arranged directly below the end of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com