Straw returning device

A straw and outer cover technology, applied in the field of straw returning devices, can solve the problems of complex structure, high cost, and low efficiency, and achieve the effects of protecting the environment, low cost, and avoiding incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

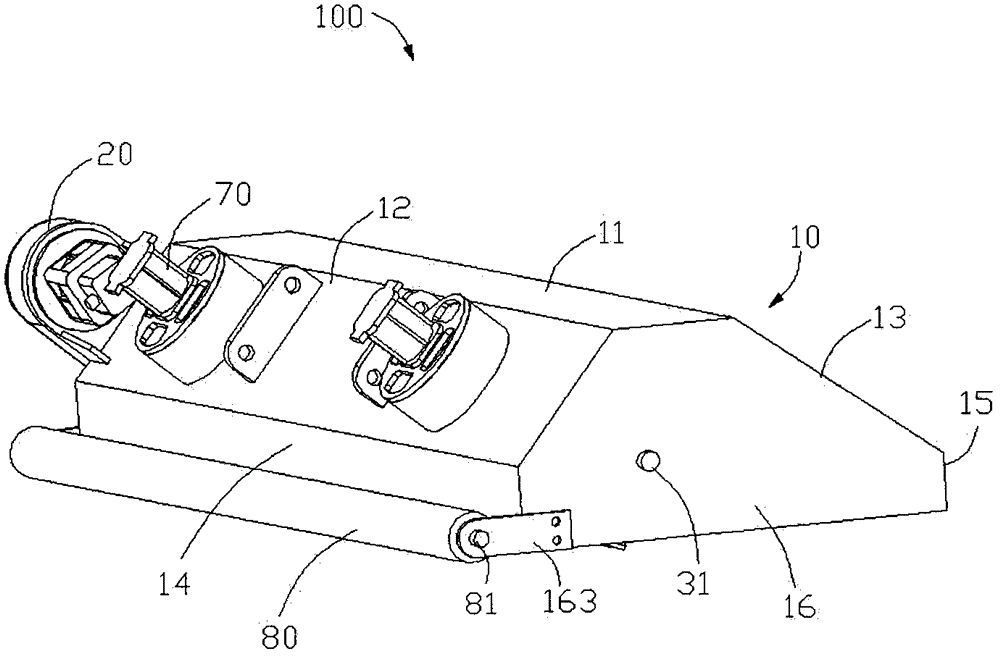

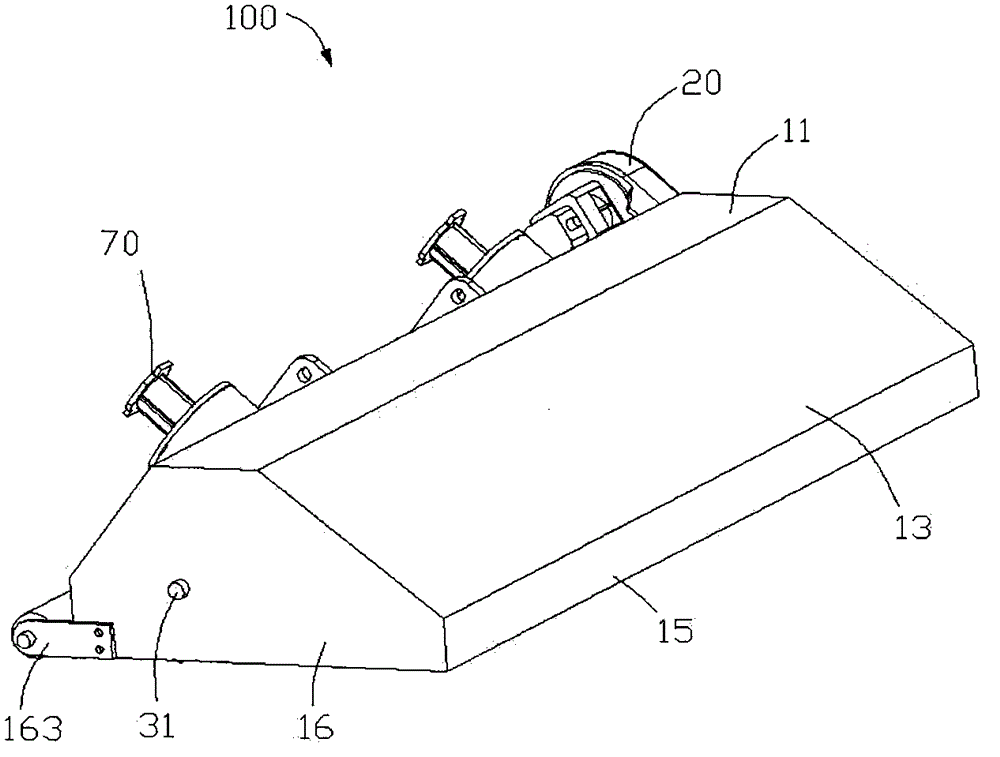

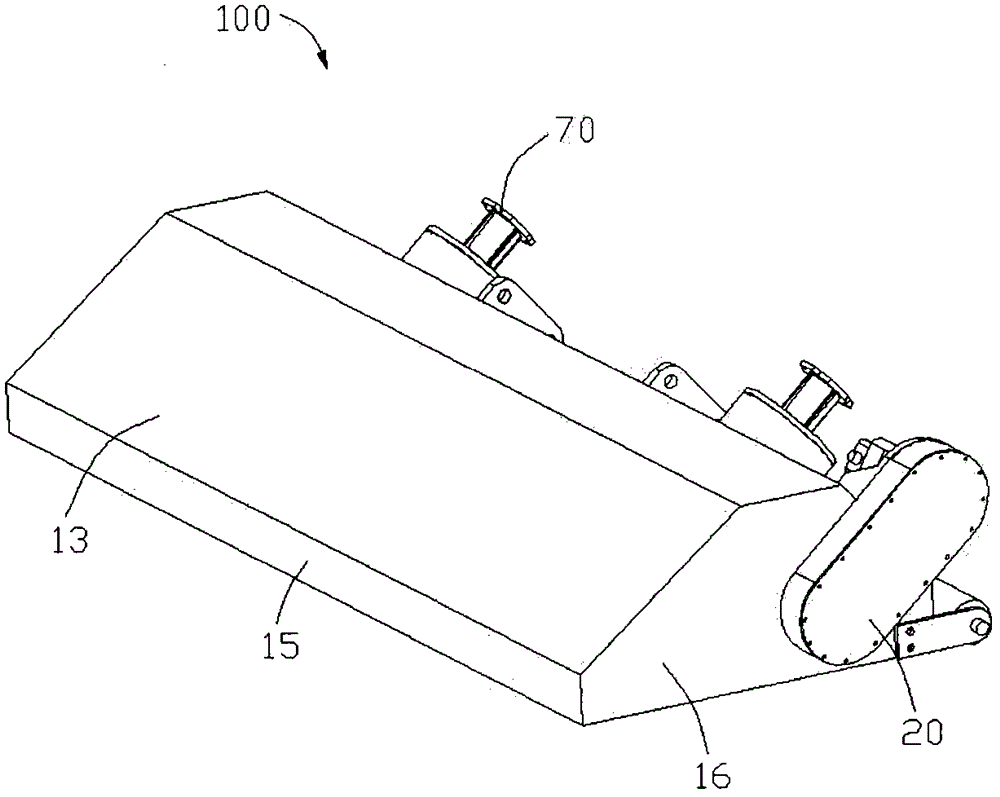

[0027] see Figure 1 to Figure 4 , In a preferred embodiment of the present invention, a straw returning device 100 includes an outer cover 10 , a driving structure 20 , a crushing structure 60 , a plurality of ventilation structures 70 and a leveling rod 80 . The crushing structure 60 includes a rotating rod 30 , a plurality of blades 40 and a plurality of crushing knives 50 . In this embodiment, there are two ventilation structures 70, and the leveling rod 80 is a cylinder. The straw returning device 100 is used to crush various crops, such as straws of corn, cotton, rapeseed, sorghum, wheat, rice, weeds, etc., and is installed on a walking platform, such as a tractor or track wheels.

[0028] The outer cover 10 includes a top panel 11 , a first cover panel 12 , a second cover panel 13 , a front panel 14 , a rear panel 15 and two side panels 16 . The top plate 11, the first cover plate 12, the second cover plate 13, the front plate 14, the rear plate 15, and the two side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com