Paper added with tobacco stalk and preparation method and device thereof

A tobacco straw and paper technology, applied in the field of papermaking, can solve the problems of affecting the performance of paper, the decrease of paper strength, a large amount of chemical wastewater, etc., and achieve the effects of avoiding the use of chemical reagents, low paper strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

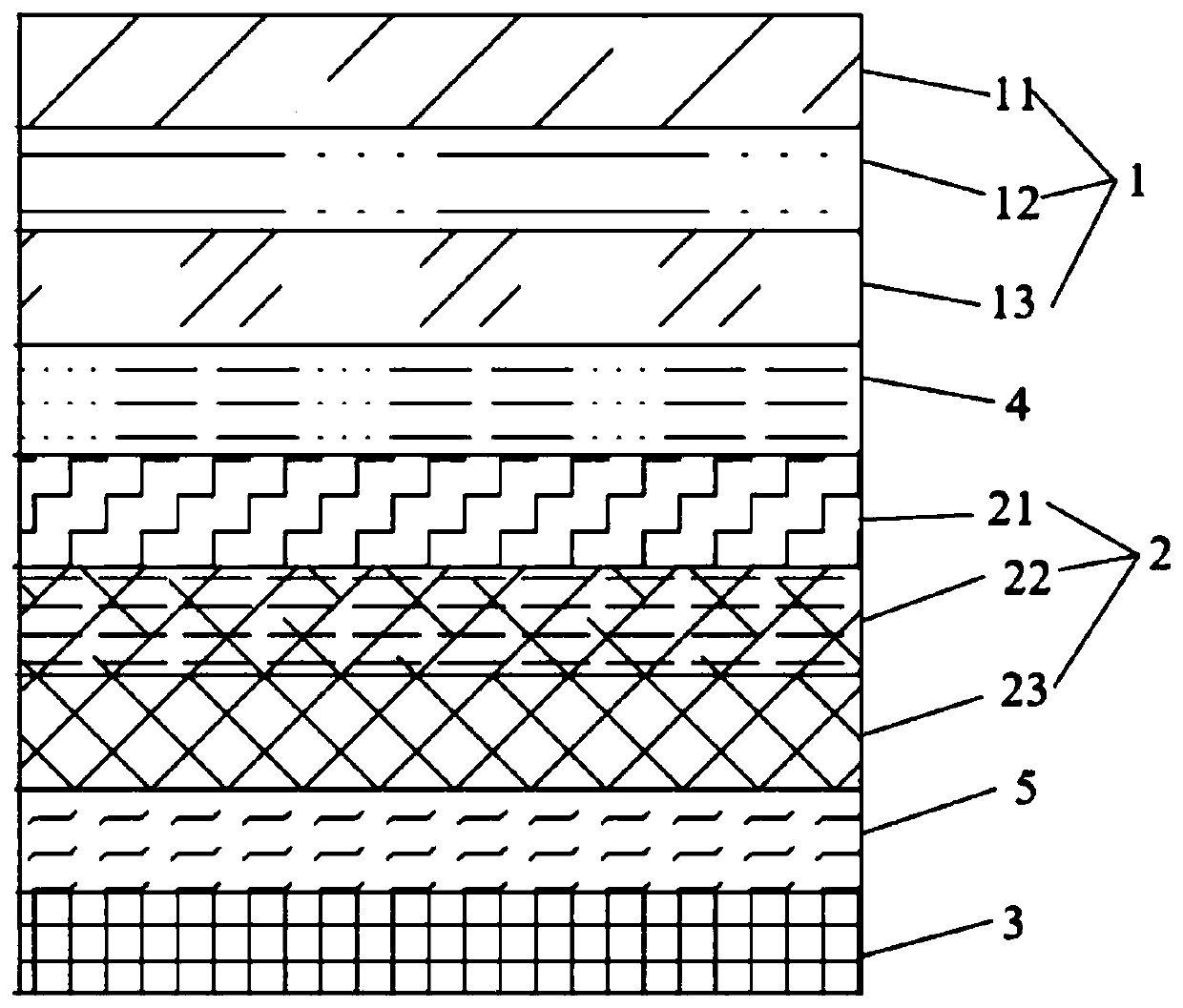

[0043] Such as figure 1 As shown, a paper with tobacco stalks added in this embodiment is sequentially arranged as a coating layer 1, a front sizing layer 4, a base paper layer 2, a back sizing layer 5, and a back coating layer 3, wherein , the coating layer 1 is provided with a surface coating layer 11, a middle coating layer 12, and a bottom coating layer 13 from top to bottom, and the base paper layer is a top paper layer 21, a core paper layer 22, and a bottom paper layer from top to bottom. Layer 23, the surface coating layer 11, the middle coating layer 12, and the bottom coating layer 13 are the layer structure formed by coating the surface paper layer 21 with the same or different coatings for 3 times, and the back coating layer 3 is the coating layer using the same or different coatings. The layer structure formed by coating the paint on the lower surface of the backing paper layer 23, as a specific implementation method, the material coated with the coating layer 1 i...

Embodiment 2

[0056] In the paper with tobacco stalks added in this example, the mass fraction of tobacco stalk powder added to the face paper layer is 0.5%, the rest of the composition is the same as in Example 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0058] In the paper with tobacco stalks added in this example, the mass fraction of tobacco stalk powder added to the face paper layer is 1%, the rest of the composition is the same as in Example 1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com