A method for preparing plywood by using discarded medical masks and plywood

A technology for plywood and masks, which is applied in the joining of wooden veneers, chemical instruments and methods, and manufacturing tools, etc., can solve the problems of difficulty in recycling, increase the burden of environmental pollution, etc., and achieve mechanical properties such as avoiding incineration treatment and gluing strength. Excellent, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare plywood as follows:

[0046] Step 1: Cut off the mask belt and metal nose clip from the discarded medical mask, and take out and flatten the meltblown cloth and non-woven fabric in it.

[0047] In the second step, five 1.5mm thick poplar veneers are selected and placed in an oven at 60° C. to dry for 5 minutes, with a moisture content of about 14%.

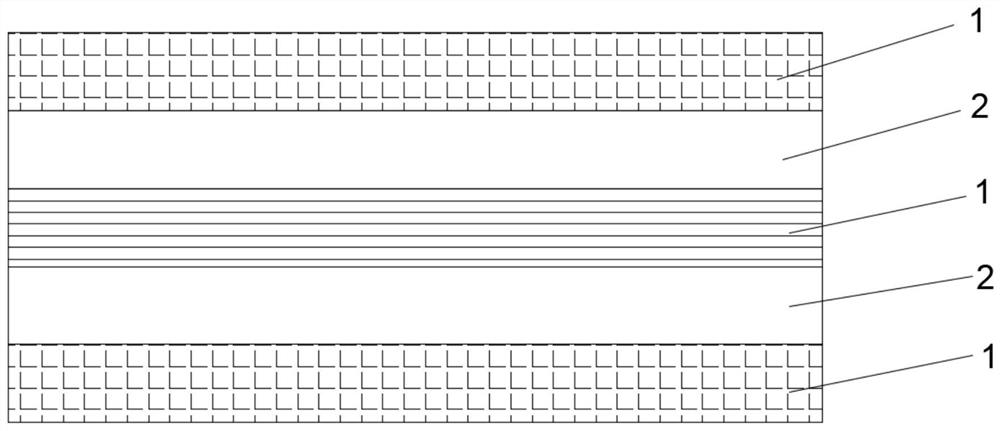

[0048] The third step is to assemble the blank. Place 20g / m between adjacent layers of veneers 2 Meltblown cloth and non-woven fabric, 1% sanding powder, and the adjacent layers of veneer textures are placed perpendicular to each other.

[0049] Step four, hot pressing and activation. The assembled slab was placed in a hot press for hot pressing and voltage activation at the same time. The hot pressing temperature was 165° C., the pressure was 1.0 MPa, the time was 40 s / mm, and the negative electrode voltage was 10 kV.

Embodiment 2

[0051] Prepare plywood as follows:

[0052] Step 1: Discard the medical mask minus the mask strap and metal nose clip, and take out and flatten the meltblown cloth in it.

[0053] In the second step, seven 0.8mm thick eucalyptus veneers are selected and placed in an oven at 60° C. for drying for 10 minutes, with a moisture content of about 8%.

[0054] The third step is to assemble the blank. Place 100g / m between adjacent layers of veneers 2 Discarded meltblown cloth, 10% sawdust powder, and adjacent layers of veneer textures are placed perpendicular to each other.

[0055] Step four, hot pressing and activation. The assembled slab is placed in a hot press for hot pressing and voltage activation at the same time. The hot pressing temperature is 180°C, the pressure is 1.5MPa, the time is 90s / mm, and the negative electrode voltage is 20kV.

Embodiment 3

[0057] Prepare plywood as follows:

[0058] Step 1: Discard the medical mask minus the mask strap and metal nose clip, and take out and flatten the meltblown cloth in it.

[0059] In the second step, three 3.5mm thick fir veneers are selected and placed in an oven at 50° C. for 20 minutes, with a moisture content of about 6%.

[0060] The third step is to assemble the blank. Place 50g / m between adjacent layers of veneers 2 Meltblown cloth, 7% sanding powder, and the adjacent layers of veneer textures are placed perpendicular to each other.

[0061] Step four, hot pressing and activation. The assembled slabs were placed in a hot press for hot pressing and voltage activation at the same time. The hot pressing temperature was 190° C., the pressure was 1.2 MPa, the time was 30 s / mm, and the negative electrode voltage was 15 kV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com