Device for recycling laminated glass waste material

A laminated glass and waste recycling technology, applied in plastic recycling, recycling technology, solid waste removal, etc., can solve the problems of poor effect, inability to separate film and glass, etc., to achieve uniformity, separation, and structural design Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

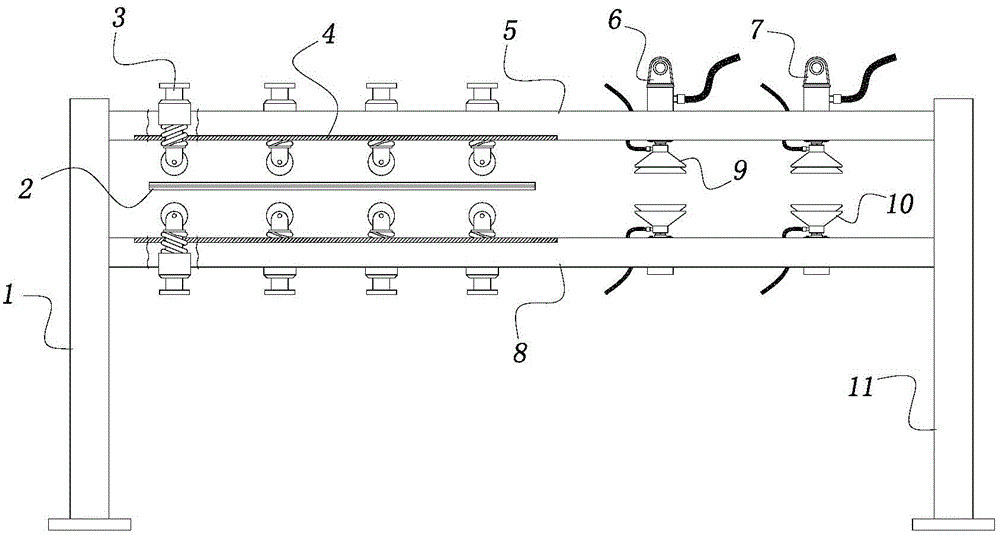

[0009] See figure 1 , the present invention includes a left column 1 and a right column 11 and an upper beam 5 and a lower beam 8 erected between them, the left half of the upper beam 5 and the lower beam 8 constitute a heating section, and the right half constitutes a dismantling section. part. The laminated glass 2 is heated up in the heating section, and the separation between the glass and the film is completed in the dismantling section.

[0010] In the heating section, the lower surface of the upper beam 5 and the upper surface of the lower beam 8 are equipped with electric heating plates 4, and the electric heating plates 4 convert electric energy into thermal energy, so that the space between the heating section, the upper beam 5 and the lower beam 8 The temperature rises and maintains a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com