Wooden box notching machine

A technology of corner cutting machine and wooden frame, which is applied in the direction of wood processing equipment, manufacturing tools, mitering working devices, etc., can solve the problems of low defective or scrap rate, high corner cutting efficiency, low processing efficiency, etc., and achieve defective products Or the effect of low scrap rate, high corner cutting precision and high corner cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

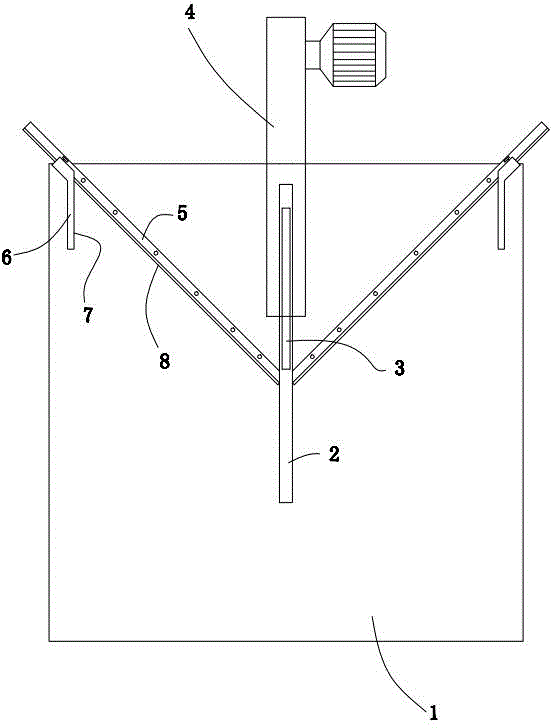

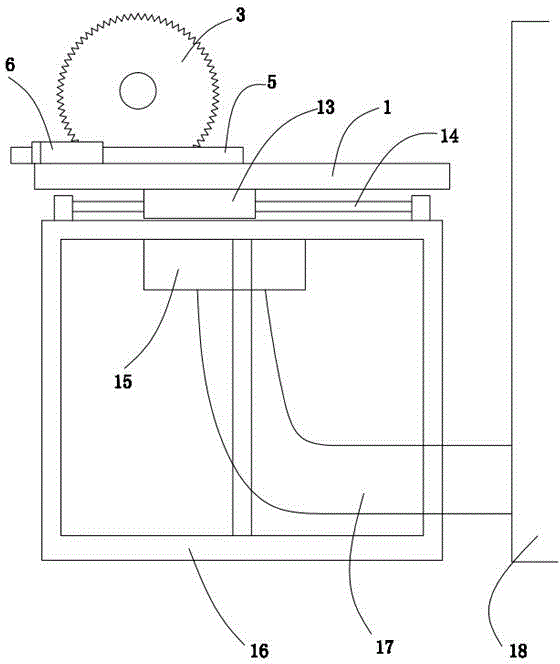

[0027] Embodiment: a kind of wooden frame chamfering machine (see attached figure 1 attached image 3 ), including a frame 16 on which a working table 1 and a cutting tool 4 that can slide relative to the frame are arranged.

[0028] Cutting knife is fixed on the frame, and cutting knife comprises cutting knife 3 and drives the motor that cutting knife rotates. The top of frame is fixed with two parallel guide shafts 14 by bearing, and guide shaft is parallel to cutting knife, and the lower surface of worktop is fixed with guide sleeve 13, and guide sleeve is sleeved on the guide shaft. A slit 2 is arranged on the working table, the width of the slit is adapted to the thickness of the cutting knife, and the position of the slit corresponds to the cut position.

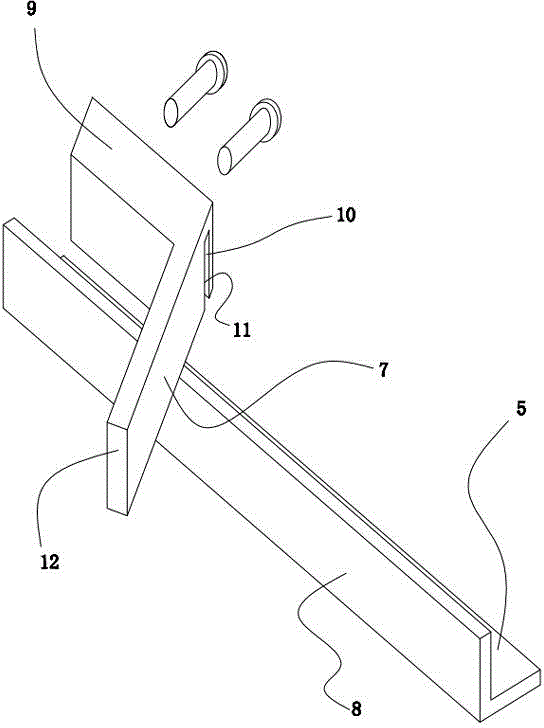

[0029] Two mutually perpendicular retaining bars 5 are fixed on the work table, and the symmetrical lines of the two retaining bars coincide with the cutting knife. The retaining bar is angle steel, one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com