A gluing system including the machine

A technology of wrapping the machine and gluing, applied in book binding, adhesive for binding, printing, etc., can solve the problems of glue liquid solidification when exposed to air, difficult to accurately control the amount of glue removal, and freezing of rubber rollers. , to achieve the effect of precise control of glue output, large promotion and application value, and easy repair and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

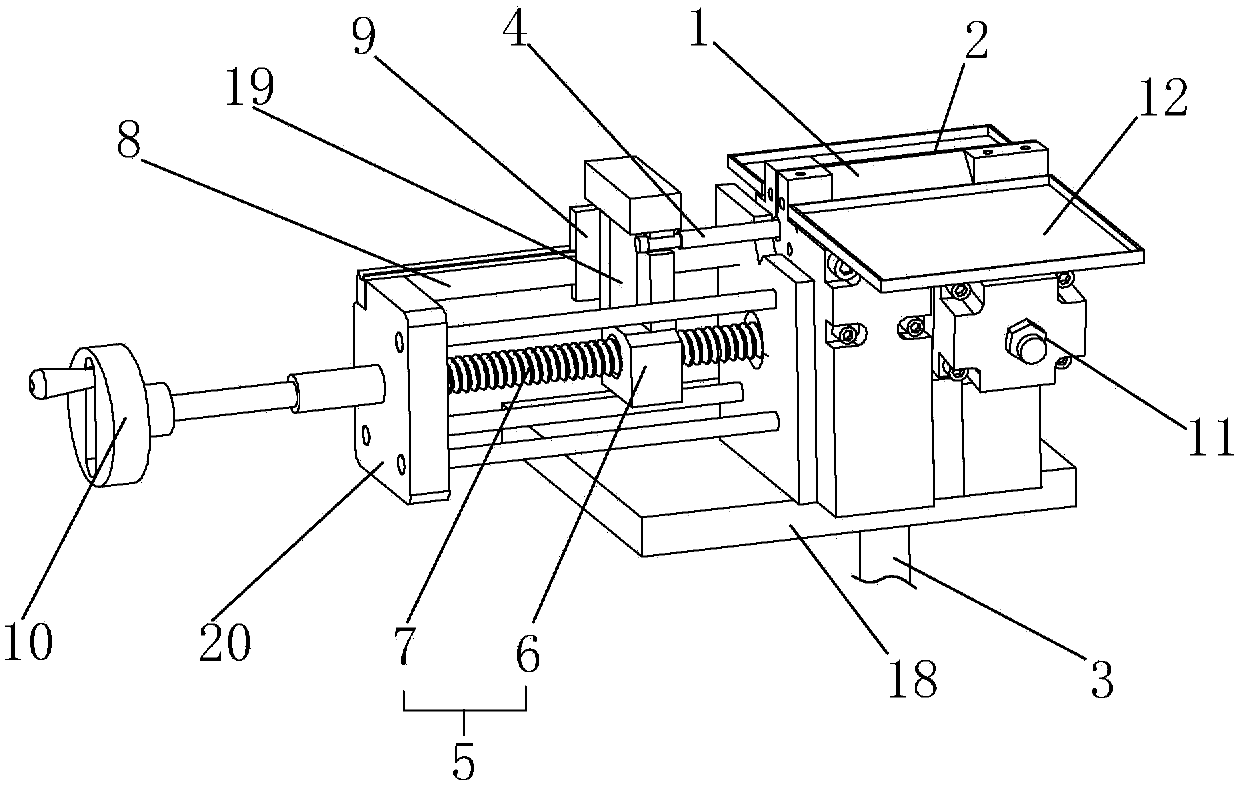

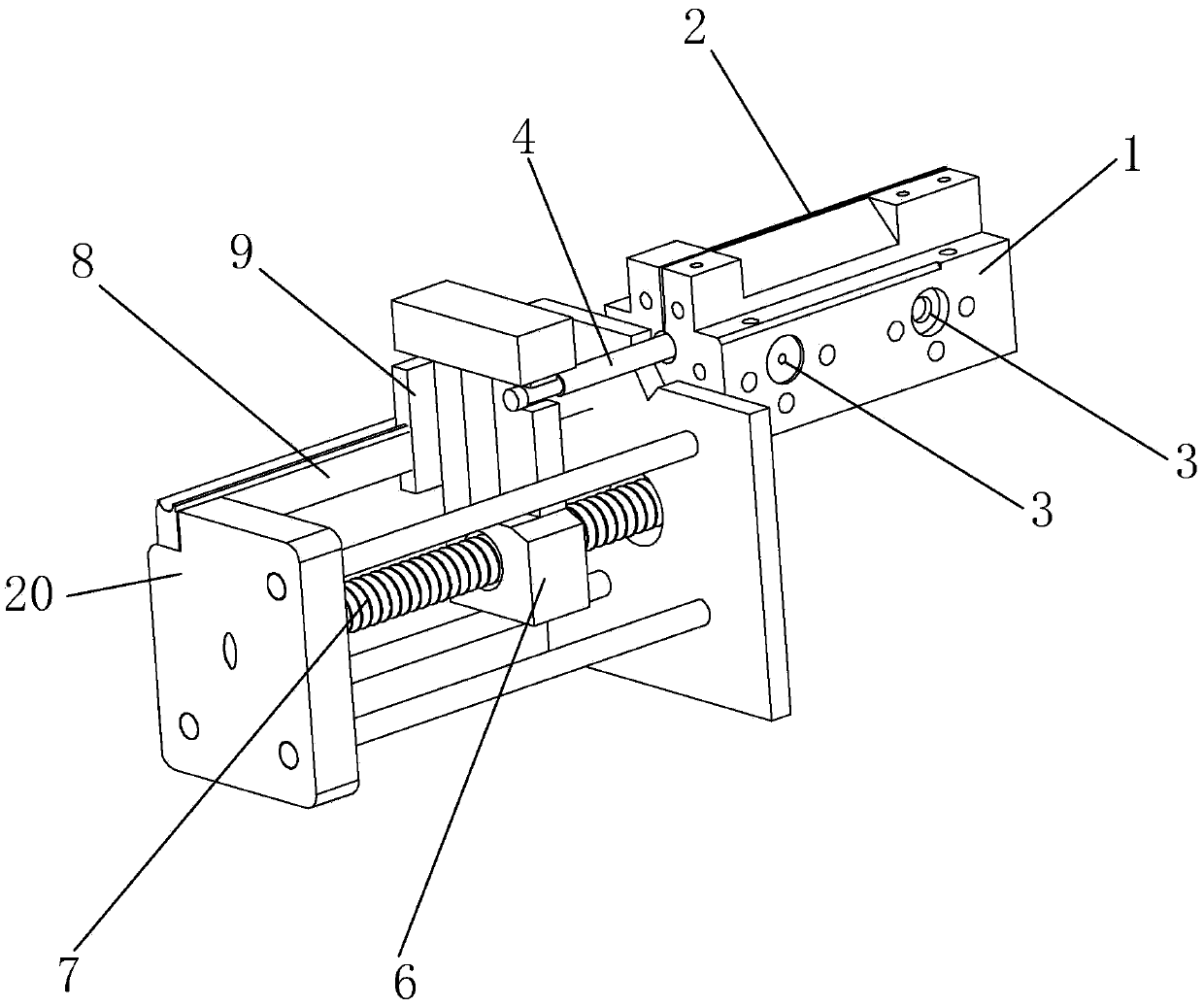

[0042] Embodiment one: see image 3 and Figure 5 , a kind of gluing system of the bag machine, which is arranged on the frame of the bag machine, before the bag body and the receiving mechanism of the bag machine, and after entering the mechanism, the gluing system of the bag machine It includes a glue outlet mechanism and a glue volume adjustment mechanism, among which:

[0043] The glue-discharging mechanism includes a glue-discharging platform 1. The glue-discharging platform 1 is in a "convex" shape as a whole, including an upper part and a lower part. The lower part is a horizontal seat, and the upper part is a raised part. The raised part is located in the middle of the horizontal seat. Steps are formed with the horizontal seat in the left and right directions of the raised part to facilitate the installation of subsequent parts. The glue outlet 1 provides glue for the glue brushing operation of the package machine and paints books or books. The glue outlet 1 The side...

Embodiment 2

[0046] Embodiment two: see image 3 and Figure 5 , a gluing system including the machine, including a gluing mechanism and a gluing volume adjusting mechanism, wherein:

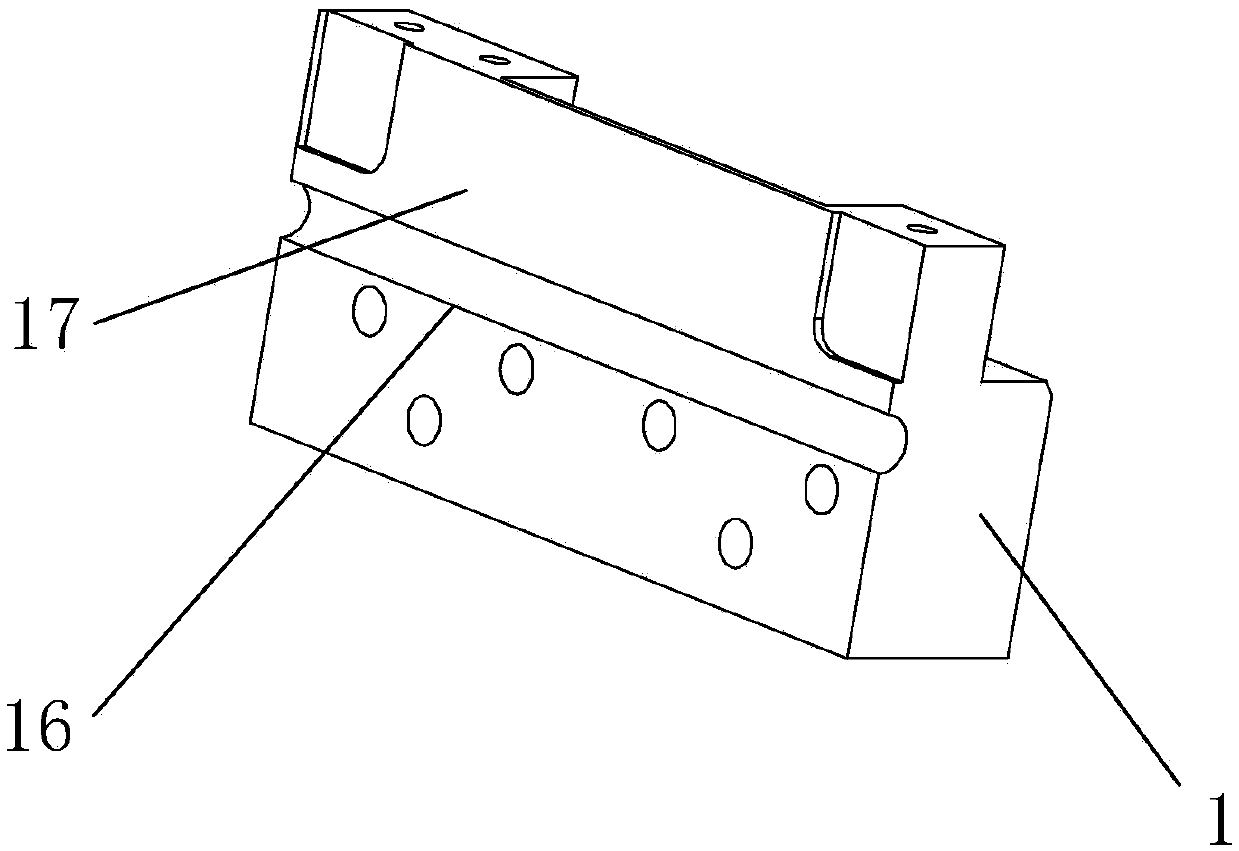

[0047] The glue-discharging mechanism includes a glue-discharging platform 1, which is provided with a glue inlet 3, a glue-discharging groove 2 is opened on the upper part of the glue-discharging platform 1, and a glue storage cavity 16 is opened inside the glue-discharging platform 1 , the glue storage chamber 16 is located at the bottom of the glue outlet tank 2, the glue outlet 17 is between the notch of the glue outlet groove 2 and the glue storage chamber 16, and the glue inlet 3 communicates with the glue outlet tank 2 through the glue storage chamber 16 ;

[0048] The glue amount adjusting mechanism includes an adjustment rod 4, which is inserted in the glue outlet 2, and the adjustment rod 4 is movably connected with the glue outlet 2, and the glue outlet 2 is controlled by the adjustment rod 4 T...

Embodiment 3

[0050] Embodiment three: see image 3 and Figure 5 , a gluing system including the machine, including a gluing mechanism and a gluing volume adjusting mechanism, wherein:

[0051] The glue-discharging mechanism includes a glue-discharging platform 1, which is provided with a glue inlet 3, a glue-discharging groove 2 is opened on the upper part of the glue-discharging platform 1, and a glue storage cavity 16 is opened inside the glue-discharging platform 1 , the glue storage chamber 16 is located at the bottom of the glue outlet tank 2, the glue outlet 17 is between the notch of the glue outlet groove 2 and the glue storage chamber 16, and the glue inlet 3 communicates with the glue outlet tank 2 through the glue storage chamber 16 ;

[0052] The glue amount adjusting mechanism includes an adjustment rod 4, which is inserted in the glue outlet 2, and the adjustment rod 4 is movably connected with the glue outlet 2, and the glue outlet 2 is controlled by the adjustment rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com