Mixed aerosol spraying device

A mixed gas and aerosol technology, applied in the direction of liquid distribution, etc., can solve the problems of inconvenient and quick mixing of two materials, unsatisfactory users, complicated structure, etc., and achieve the effect of good sealing performance, simple valve structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

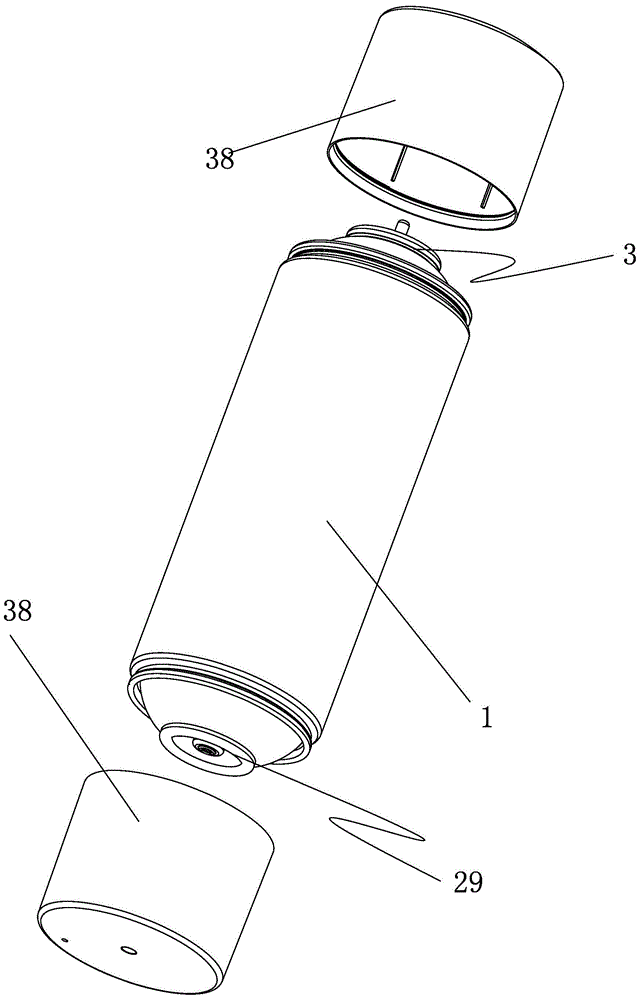

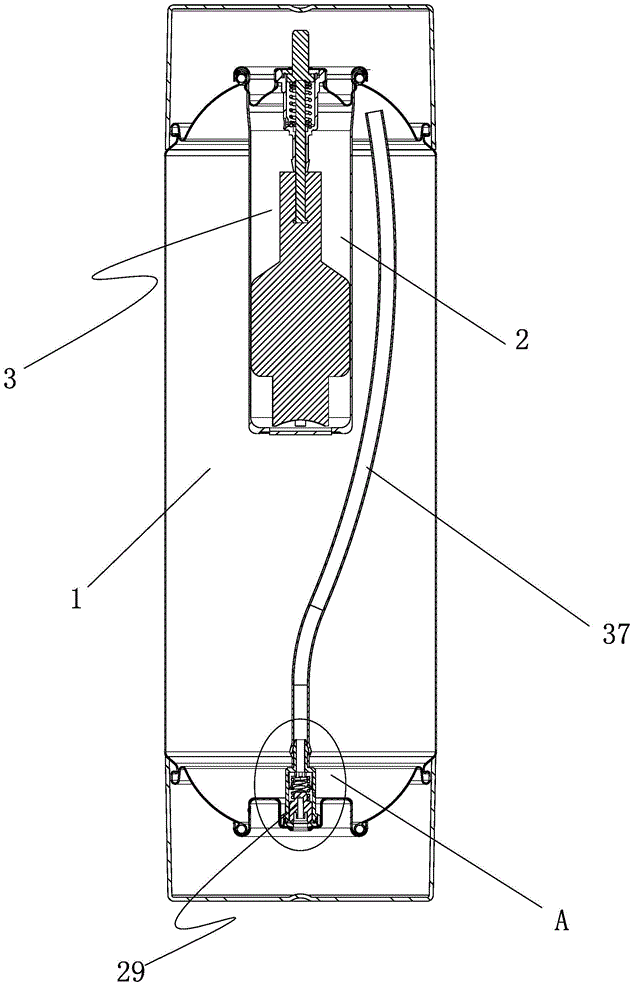

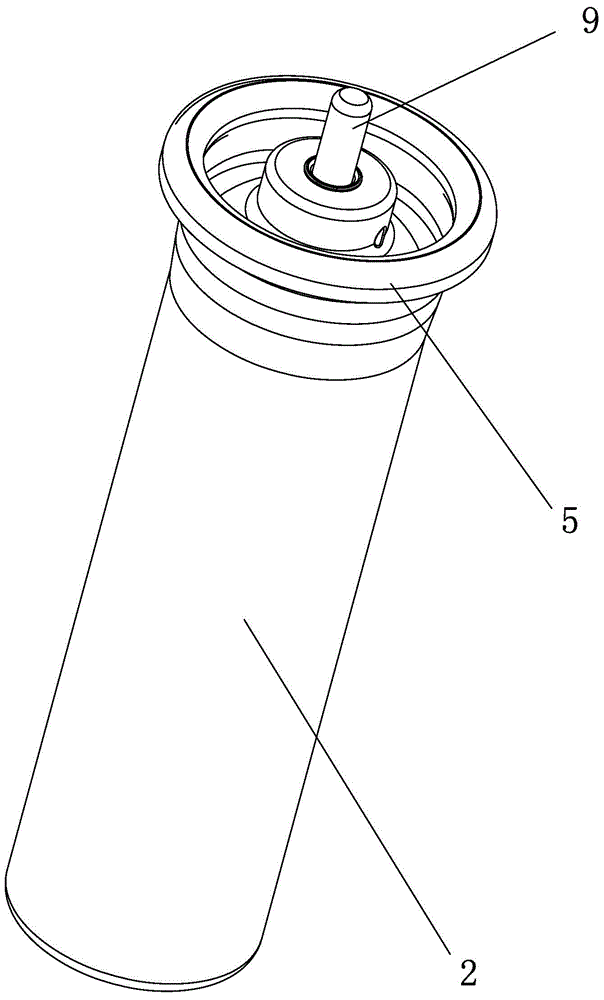

[0026] Such as Figures 1 to 7 A mixed aerosol paint spraying device shown includes a tank body 1 for containing the first material, and an inner container 2 for independently containing the second material is sealed in one end of the tank body 1. In the inner container 2 A piercing valve mechanism 3 capable of piercing the liner 2 to mix the second material with the first material is provided inside, and a spray valve 29 communicating with the tank body 1 is sealed at the other end of the tank body 1 . When the present invention is used, it only needs to press the piercing valve mechanism 3 firmly to pierce the lower end of the inner container 2, and the second material contained in the inner container 2 can be quickly mixed with the first material in the tank body 1, and the mixed material It can be sprayed out through the spray valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com