Glass conveying platform with glass turnover function

A conveying table and glass technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve problems such as unsafe efficiency and achieve the effect of solving the problem of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

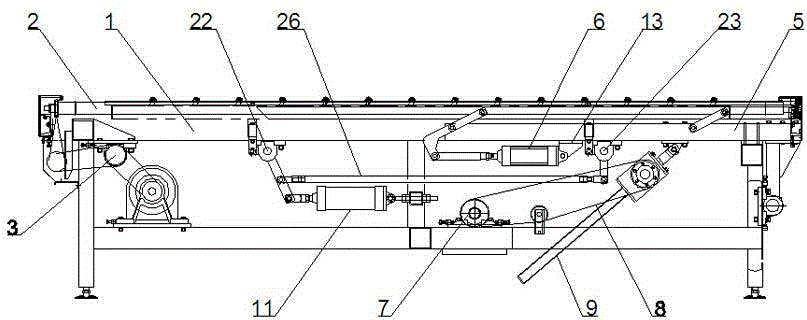

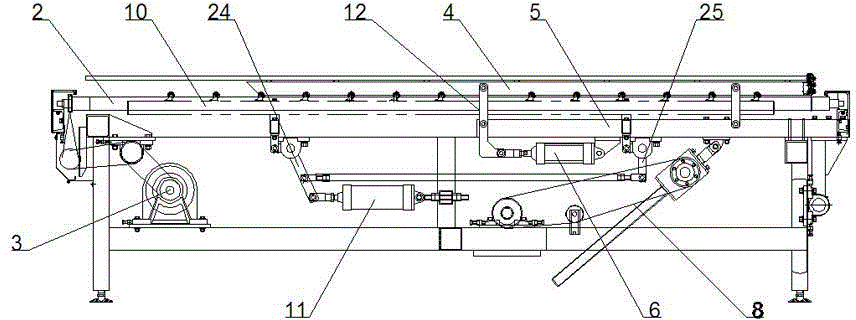

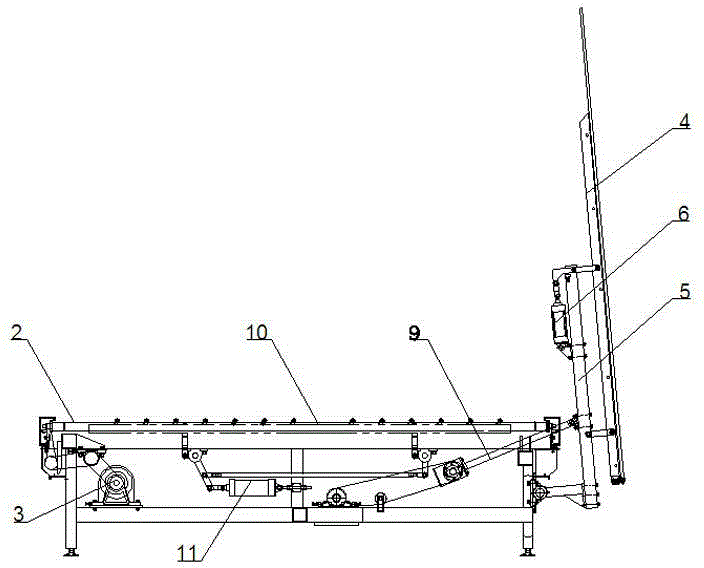

[0020] As shown in the figure: a glass conveying platform with glass turning function, including a frame 1 and a plurality of conveying rollers 2 arranged on the frame 1, and a plurality of conveying rollers 2 are parallel to each other and arranged along the glass conveying direction to form a glass On the conveying surface, the conveying rollers 2 rotate around their respective longitudinal axes through the drive mechanism 3, and the glass conveying table also includes an inverting mechanism for glass inversion, a control mechanism for controlling the inverting mechanism to invert, and transfers the glass from the conveying rollers 2 Move to the turning mechanism or the lifting mechanism that moves the glass from the turning mechanism to the conveying roller 2,

[0021] Described overturning mechanism comprises overturning arm 4, overturning support beam 5, overturning arm transmission assembly and driving cylinder 6, and the above parts are two sets, symmetrically arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com