Box step for overhauling overhead line system of electrified railway

A technology of electrified railway and catenary, applied to ladders, buildings, building structures, etc., to achieve the effect of high practical value, low cost, and convenient daily transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

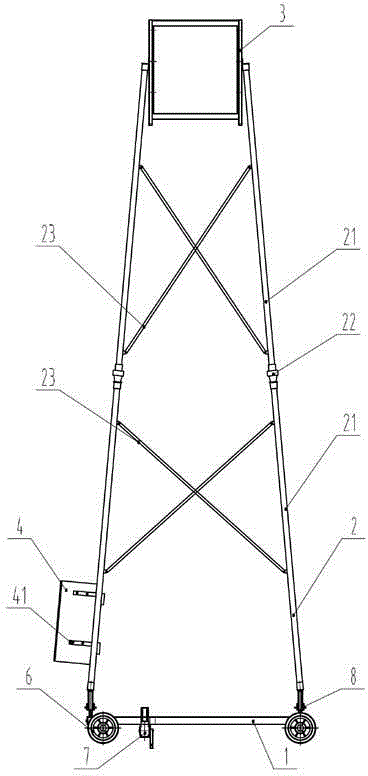

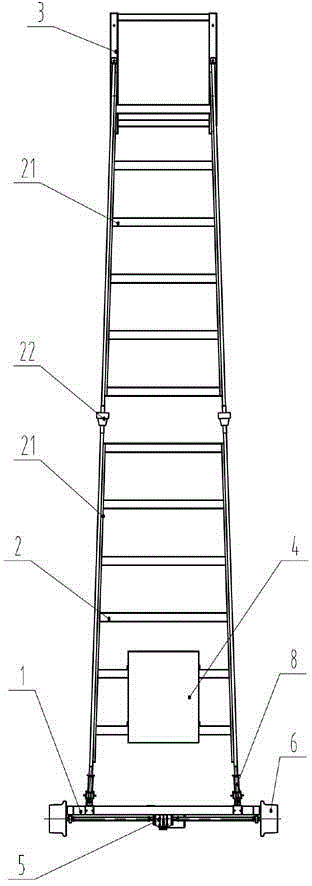

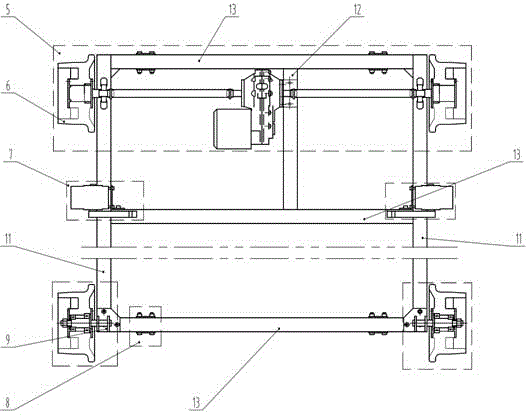

[0025] Such as figure 1 and figure 2 As shown, a kind of vehicle ladder for the maintenance of electrified railway catenary according to the present invention includes a working platform 3, a detachable ladder frame 2 and a ladder car chassis 1, and the working platform 3 is installed on the top of the detachable ladder frame 2, The four columns of the working platform 3 are provided with four through holes from high to low, and are connected with the ladder frame 2 through the through holes, and the height of the working platform 3 can be adjusted through the four through holes. The detachable ladder frame 2 is installed on the ladder car chassis 1, and the working platform 3, the detachable ladder frame 2 and the ladder car chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com