A kind of roadway one-time forming smooth blasting method

A smooth blasting and roadway technology, which is applied in blasting and other directions, can solve the problems of lower labor productivity and construction progress, complicated procedures, and inability to guarantee the quality of smooth blasting, so as to reduce the amount of secondary repairs, weaken the mutual clamping effect, Improved security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, the excavated rock section is 4.5m wide and 3.6m high, and the depth of each blast hole is controlled to be 2.5m.

[0021] A roadway forming smooth blasting method, firstly excavate the rock formation, and then carry out the following steps:

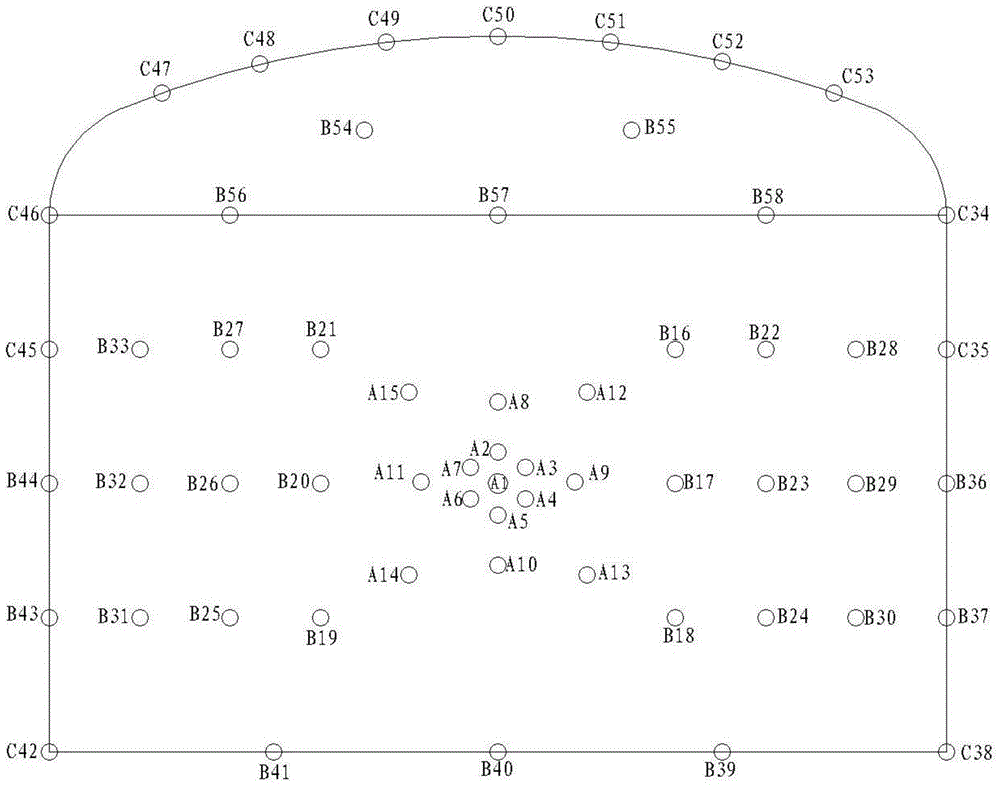

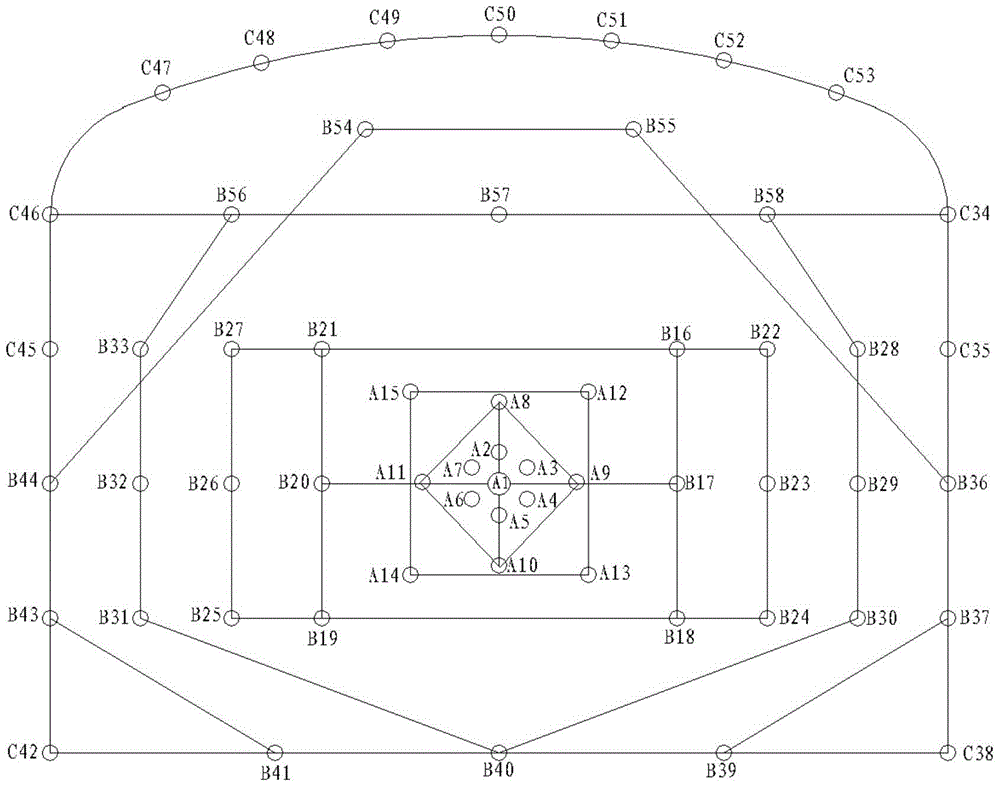

[0022] (1) Layout setting of blast holes: determine the center cut hole A1 on the rock formation, set the first layer of cut holes on the periphery of A1, set the second layer of cut holes around the first layer of cut holes, and set the second layer of cut holes on the periphery of the second layer of cut holes Set the third layer of cutouts around the groove; set the first layer of caving holes around the third layer of cutouts, set the second layer of caving holes outside the first layer of caving holes, and set the third layer of Layer avalanche eyes, set the fourth layer avalanche eyes on the periphery of the third layer avalanche eyes; set a layer of peripheral eyes on the periphery of the fourth layer av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com