Large transport airplane control loading simulator

A technology of load simulation and transport aircraft, which is applied in the field of flight simulators, can solve problems such as the inability to simulate elevator trim, the inability to realize the change of the steering column, and the inability to simulate the working conditions of the control system during automatic driving, so as to reduce and eliminate driving fatigue , Improve the effect of flight training benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

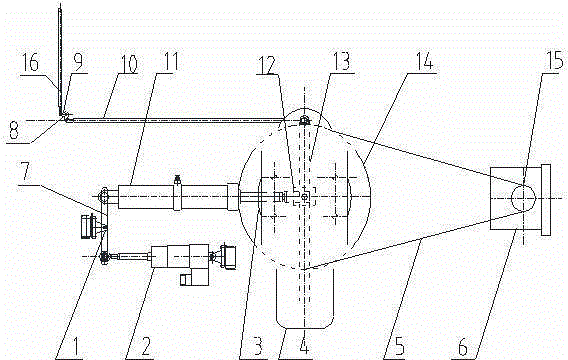

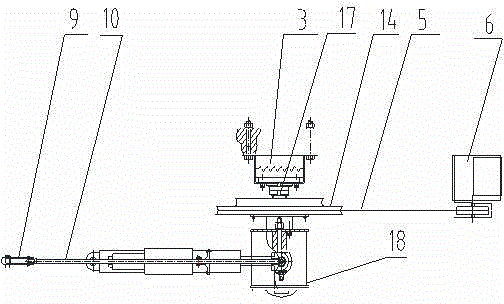

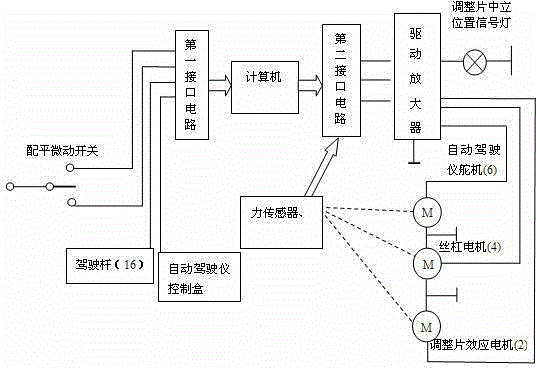

[0029] The implementation process of the present invention will be described below with reference to the accompanying drawings.

[0030] A control load simulation device for a large transport aircraft of the present invention includes a mechanical system and a control system;

[0031] Ⅰ. The composition of the mechanical system is as follows:

[0032] like figure 1 , figure 2 As shown, one end of the transmission rod (10) is connected with one end of the rocker arm (9), the other end of the rocker arm (9) is connected with the driving rod (16), and the other end of the transmission rod (10) is connected with the lead screw (13) connected to the upper end, the rocker arm (9) can rotate around the third fulcrum (8);

[0033] The inner wall of the sliding sleeve engages with the external thread of the lead screw (13) through threads, and there is a bearing in the middle of the sliding sleeve (12). ) drives the lead screw (13) to rotate, the sliding sleeve (12) can move up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com