An accordion soundhole cover capable of self-levelling

An automatic leveling and accordion technology, applied in the directions of accordions, wind instruments, instruments, etc., can solve the problems of cumbersome sound hole cover leveling procedures, difficult effects, poor effects, etc., achieve significant economic and social value, and improve product quality. And the effect of production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

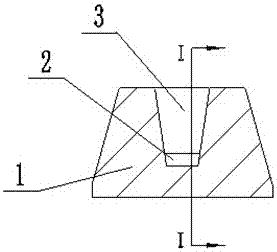

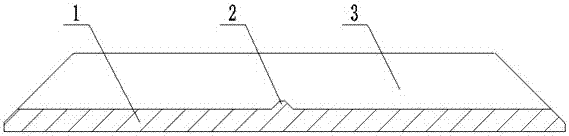

[0018] Such as Figure 1~2 As shown in the present invention, a self-leveling accordion sound hole cover, the sound hole cover body 1 is processed with a key rod groove 3 connected to the key rod 6, and the cross-sectional shape of the key rod groove 3 is bottom An inverted trapezoidal structure with shorter sides, the middle part of the key rod groove 3 is provided with a transverse protrusion 2 perpendicular to the key rod groove 3 .

[0019] When the key rod groove 3 is set as an inverted trapezoidal groove body, since both sides of the key rod groove 3 are sloped surfaces, even if the sound hole cover body 1 is not aligned before installation, when the key rod 6 is pressed down for installation, it will slide down along the slope, thereby Adjust the sound hole cover body 1. Certainly from this principle we know that the width of the bottom edge of the key bar groove 3 must be equal to or slightly greater than the rear diameter or thickness of the key bar 6, and the gap be...

Embodiment 2

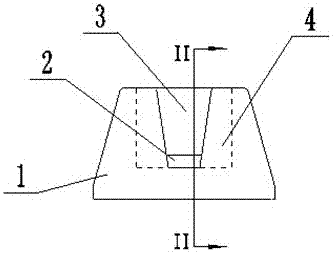

[0022] Such as Figure 3-6 As shown in the present invention, a self-leveling accordion sound hole cover, the sound hole cover body 1 is processed with a key rod groove 3 connected to the key rod 6, and the cross-sectional shape of the key rod groove 3 is bottom An inverted trapezoidal structure with shorter sides, the middle part of the key bar groove 3 is provided with a transverse protrusion 2 perpendicular to the key bar groove 3; the two sides of the key bar groove 3 are processed with symmetrical sizing grooves 4 ; One end of the key rod groove 3 is provided with a plug 5, and the sound hole cover body 1 and the plug 5 are integrally formed.

[0023] On the basis of embodiment 1, in this embodiment, symmetrical sizing grooves 4 are processed on both sides of the lateral protrusion 2 of the key rod groove 3, and the lateral depth of the sizing grooves 4 is 1-4mm, and each is a sizing groove 4. The length along the installation direction of the key rod 6 is 5-15 mm. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com