Xenon target preparation device for reactor irradiation production of I-125 (iodine-125)

An I-125, preparation device technology, which is applied to targets for generating nuclear reactions, transformations in nuclear reactors, electrical components, etc. Controlling the risk of radioactive contamination, efficient and safe preparation, reducing workplace effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

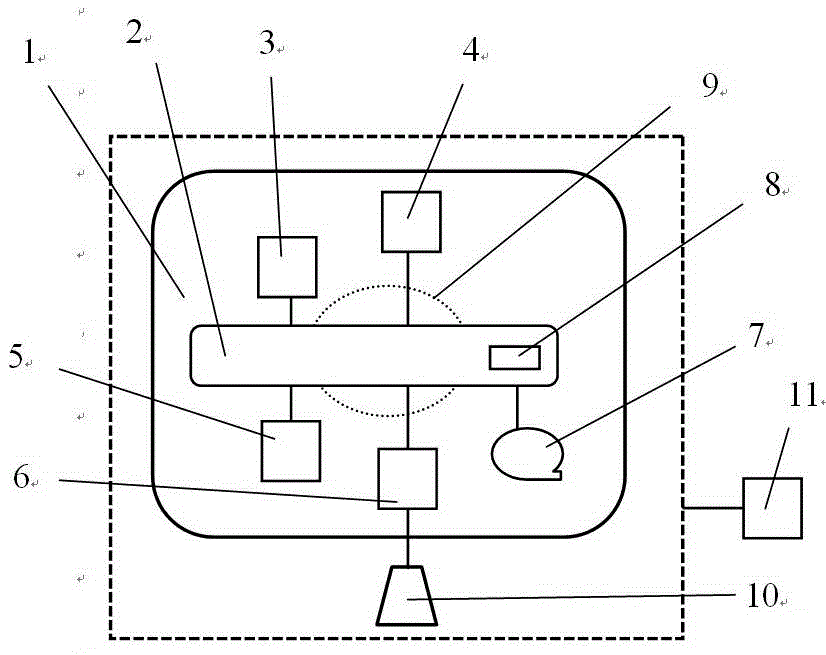

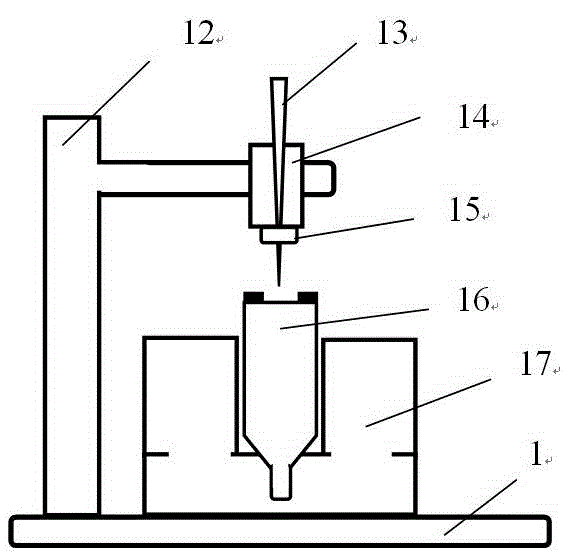

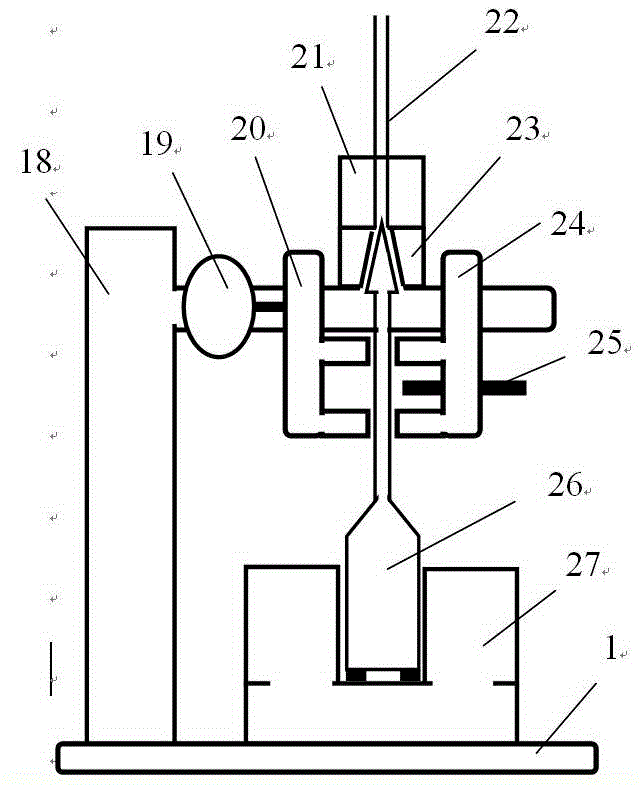

[0022] figure 1 It is a block diagram of the overall structure of a xenon target preparation device for reactor irradiation production I-125 of the present invention, figure 2 It is a structural schematic diagram of the target opener in the present invention, image 3 It is a structural schematic diagram of the solder filling device in the present invention, Figure 4 It is a structural schematic diagram of an air-inverting tank in the present invention. exist Figure 1~Figure 4Among them, the preparation device of the xenon gas target for I-125 production of the present invention includes a stand 1, an air dump tank 2, a target opener 3, a raw material tank 4, a storage device 5, a welding device 6, a vacuum pump 7, a pressure gauge 8. Liquid nitrogen pump 9, fusion welding power supply 10, and controller 11. The connection relationship is that the degassing tank 2, the target opening device 3, the raw material tank 4, the storage device 5, the welding device 6, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com