Method and apparatus for estimating dosing error in a selective catalytic reduction system

A selectivity and error technology, applied in chemical instruments and methods, mechanical equipment, separation methods, etc., can solve the problems of system instability, sensor increasing system complexity and cost, ammonia sensor reliability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] SCR devices can be used in a variety of applications where it is desired to reduce NOx levels in an air stream. Such applications may include, but are not limited to, boilers, gas turbines, and internal combustion engines (eg, diesel engines).

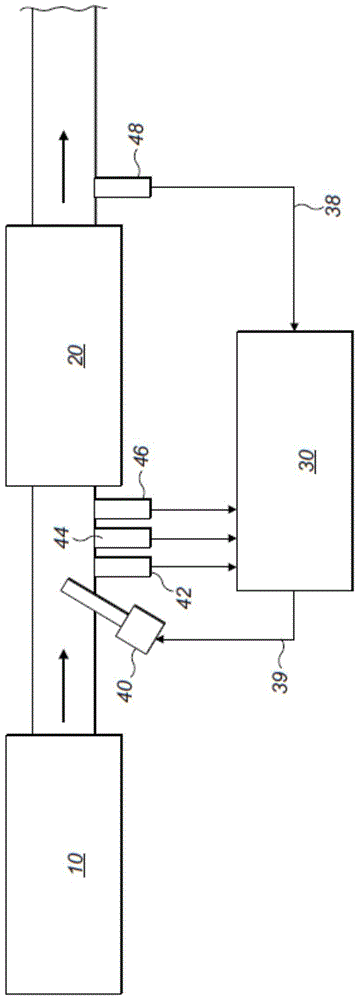

[0024] figure 1 Internal combustion engine 10 is shown with SCR device 20 at the exhaust of internal combustion engine 10 . SCR device 20 in this arrangement may be dosed by injecting urea into the exhaust upstream of SCR device 20 using injector 40 . However, any other suitable dosing agent may alternatively be used, such as anhydrous ammonia or ammonia water, and may be added to the SCR device 20 using any suitable technique known to the skilled artisan, or may be in a separate part of the system (such as Ammonia is formed in the ammonia reactor).

[0025] A first (or upstream) NOx sensor 42 , a mass flow rate sensor 44 and a temperature sensor 46 may be arranged to measure the state of the exhaust gas upstream of the SCR d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com